- Submissions

Full Text

Aspects in Mining & Mineral Science

The Effects of Quenching Temperature on Mechanical Strength in Micro Alloyed Steel with Boron

Filho AI1*, Monteiro de Souza W2, Vilarim da Silva R1, Ribeiro Martins JB2 and da Cruz Lima LX2

1Federal Institute of Espírito Santo, University in Vitória, Brazil

2Global R&D South America-ArcelorMittal, Canada

*Corresponding author: André Itman Filho, Federal Institute of Espírito Santo, University in Vitória, Espírito Santo, Brazil

Submission: August 17, 2020;Published: December 06, 2021

ISSN 2578-0255Volume8 Issue1

Abstract

Oil Country Tubular Goods (OCTG) steels are used in the form of tubes in the casing column of the oil well walls and exhibit martensitic structure after quenching and tempering. Due to the high cost of chromium, nickel and molybdenum, an alternative is the replacement of these elements by boron, which increases the hardenability. In order to maintain the efficiency of boron in solution it is necessary to add titanium to form Titanium Nitrides (TiN), which inhibit austenitic grain growth and avoid the formation of boron nitride. In the present study samples of a coil were quenched at 850 and 1050 °C. The microstructures, hardness, yield stress, tensile strength and elongation were obtained and Lepera reagent was used to visualize the martensite after quenching. The results show that the hardness, yield stress and tensile strength at the temperature of 850 °C are higher than 1050 °C and elongation is less.

Keywords: Boron steels; Titanium nitride; Auto-tempering martensite; Hardenability

Materials and Methods

Ten samples with dimensions of 300.0x35.0mm were cut from a sheet with a thickness of 7.5mm in the longitudinal direction of rolling. Afterward, five specimens were quenched in an electric furnace at 850 and five at 1050 °C for 30 minutes. The tensile test was carried out in a universal hydraulic test machine with a capacity of 500kN and strain gauge with measurable deformation of 50mm and pulled with 1mm per minute constant strain speed according API SPEC 5CT-12 standard. After tensile tests the samples were prepared following conventional metallographic methods. The microstructures were observed by Scanning Electronic Microscope (SEM) after attack with Lepera reagent. The Vickers hardness with load of 10kgf were obtained in all specimens considering the ISO 6507-1 standard. Results represent the average of five measurements in each test piece, under all conditions of quenching.

Results

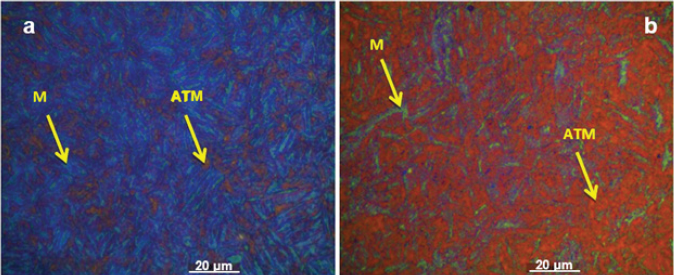

Figures 1a & 1b, show the martensite laths (blue color) and auto-tempering martensite (brown color) after quenching at 850 and at 1050 °C. Figures 1a & 1b, show the martensite laths (blue color) and auto-tempering martensite (brown color) after quenching at 850 and at 1050 °C.

Figure 1: Blue regions of martensite laths (M) and brown regions of Auto-Tempering Martensite (ATM). Quenching at 850 °C (a) and 1050 °C (b) - (Lepera, OM).

Discussion

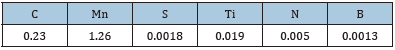

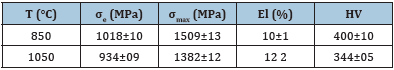

The chemical compositions shown in (Table 1) and the weight ratio Ti/N equal 3.8 indicates that all nitrogen is connected to titanium, and the boron stay free in solid solution to be effective in the formation of martensite laths after quenching [1,2]. The microstructures of martensite laths is favored by quenching temperatures above 800 °C in boron steels [3]. With regard to hardness Vickers, in (Table 2), the value at 1050 can be explained by greater amount of auto-tempering martensite formed in the cooling to room temperature that reduces the hardness of the steel. The auto-tempering microstructure is associated with the migration of carbon and carbide precipitation at the martensite. The characterization is possible with Lepera reagent attack that shows the initial martensite (blue color) and the auto-tempering martensite (brown color). It is likely that increased solubility of carbon in austenite favors the higher amount of auto-tempering martensite4. As regards elongation, the values always increase with reduces the tensiles. Meanwhile, according to literature, the presence of auto-tempering martensite improves the plasticity of the steel [4].

Table 1: Partial chemical composition of the micro alloyed steel (% in weight).

Table 2: Yield strength (σe), tensile strength (σmax), elongation and hardness values after quenching (average of five values).

Conclusion

a. After quenching, auto-tempering martensite promotes

the values reduction of hardness, yield strength and tensile

strength of the steel;

b. Lepera reagent and Vickers microhardness measurements

allow the identification of auto-tempering martensite.

Acknowledgment

The authors thank Global R&D South America - ArcelorMittal for the steel samples used in this work.

References

- Ghali SN, EL-Faramawy HS, Eissa MM (2012) Influence of boron additions on mechanical properties of carbon steel. Journal of Minerals and Materials Characterization and Engineering 11(10): 999-995.

- Shen Y, Hansen SS (1997) Effect of the Ti/N ratio on the hardenability and mechanical properties of a quenched-and-tempered C-Mn-B steel. Metallurgical and Materials Transactions A 28: 2027-2035.

- Frantov II, Golovanenko SA, Moiseev BA, Burnyashev II (1980) Influence of heat treatment on the effectiveness of microalloying of pipe steels. Metal Science and Heat Treatment 22: 842-845.

- LI C, Yuan G, Ji F, Ren D, Wang G (2016) Effects of auto-tempering on microstructure and mechanical properties in hot rolled plain C-Mn dual phase steels. Materials Science & Engineering A 665: 98-107.

© 2021 Filho AI. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)