- Submissions

Full Text

Aspects in Mining & Mineral Science

Development of Bioleaching for Extraction of Metal Values from Low-Grade Ores and Wastes

Pradhan D1*, Sukla LB1, Behera PK2 and Dash S3

1Biofuels and Bioprocessing Research Center, Institute of Technical Education and Research, India

2School of Chemistry, Sambalpur University, India

3Upendra Nath College, Fakir Mohan University, India

*Corresponding author: Debabrata Pradhan, Biofuels and Bioprocessing Research Center, Institute of Technical Education and Research, Siksha ‘O’ Anusandhan (Deemed to be University), Jagamara, Khandagiri, Bhubaneswar-751030, Odisha, India

Submission: April 23, 2021;Published: August 02, 2021

ISSN 2578-0255Volume7 Issue1

Abstract

Exploitation of bacterial activities in the mineral industries and environmental preservation are gaining much attention. Bioleaching is a useful tool to recover different metals from low-grade ores and wastes. It has proved its benefits in terms of cost and environment. It is applied to the heap operation for the processing of the large volume of different low-grade ores. The techno-economic feasibility studies and flow sheet of different sections must be given top priority during its scale up. Further genetic improvement is proposed for the understanding of the cellular metabolism of the microorganisms for the bioleaching purpose. This helps the industries by opening renewed possibilities for mineral processing technology through improved kinetics and other economic benefits. Spectroscopic technologies like Magnetic Resonance Imaging (MRI) & electron microprobe are important tools to support the dissolution mechanism of heavy metals during bioleaching. Further metal recovery process like solvent extraction and electro-winning have been coupled with the bioleaching techniques develops a comprehensive extractive metallurgy to produce the cathode grade metals.

Keywords: Bioleaching; Heap leaching; Solid wastes; Low-grade ore; Magnetic resonance imaging

Introduction

Selective microorganisms have found biotechnological applications for metal recovery. A broad term used in this area of research i.e. bio-mineral processing involves processing of flotation tailings, Run-of-the-Mine (ROM) material, and low/intermediate to high-grade ores etc. [1-3]. The application of microorganism for metal recovery has already been established for gold, copper, zinc and cobalt. Wide ranges of microorganism are involved in this process and the underlying mechanisms responsible for metal dissolution are now well known [4]. Metal dissolution using microbes is followed by hydrometallurgical processing of bioleach liquors such as through solvent extraction and electrowinning techniques [5,6]. These methods are used to purify the leach liquors and deposit the metal of interest. The most advanced bio-hydrometallurgical units are the heap Bio Leaching (BL) operations used to process lower grade ores [7-10]. This technique is becoming more and more popular due to its economical and eco-friendly advances compared to other technologies [11,12]. For successful operation of the bio-hydrometallurgical operations, the techno-economic feasibility studies and flow sheet of different sections like ore preparation, crushing, screening, bio-heap leaching, solvent extraction and electro winning are required to be developed [13-18].

Copper Heap Bioleaching

With the increased demand for copper, it has become necessary for the minerals industry to process the low-grade ores, overburden and mine tailings for its production. For the dissolution of copper from different resources, techniques like in-situ, dump and heap leaching have been applied. Nowadays heap BL is a developed technology and successfully applied for extraction of copper from different secondary sulfides. Heap BL is favored because of its numerous advantages such as simple infrastructure, shorter startup times and larger volumes of wastes being processed at lower capital and operating costs. An example of such an approach is the heap BL tests carried out at CSIR-IMMT, India. Heap BL at 15 and 30ton scales was undertaken at CSIR-IMMT for processing of the lean copper ores. About 0.09% dissolution of copper from the ore body per day was obtained from the leaching experiments. The bioleach liquor obtained after leaching was processed through solvent extraction and electro-winning [10,19-22]. The process was scaled up at different stages from lab scale shake flaks followed by column BL scale, 15 & 30ton and finally to 1000ton scale at the mine site.

Inside Bio-Heap Imaging

Magnetic Resonance Imaging (MRI) is a new technique to know the leaching behavior inside the heaps during operation. The MRI uses radio waves and strong magnetic fields to produce detailed images inside of the heap. It has a large tube consists of several powerful magnets. Various MRI techniques were used to take the image of aqueous flow fields in the heap loaded with low-grade ore. The leach solution inside the heap influences its contact with the ore particles, in consequences it controls the performance of heap. Another imaging technique is Spin Echo Single Point Imaging (SESPI). The SESPI is the most robust imaging method for the study of heap leaching containing copper ore. A bioremediation process was used to investigate the removal of Co(II) from aqueous solution. In this process, an MRI protocol rapidly obtained multiple 2D spatially resolved Co(II) concentration maps [23]. The MRI technique described the details evolution of both axial and radial concentration profiles, which further determined the total column capacity. The results represented the first concentration maps describing the bioremediation of metal ion from the contaminated water. Sometime electron microprobe techniques are helpful as important tool to evaluate the dissolution mechanism of different heavy metals during BL process.

Bioleaching of REEs

Rare Earth Elements (REEs) are increasingly important for a variety of technologies. The recycling of REEs from different scrap offers an opportunity to secure their supply in the European regions. The REEs content is very low in the above secondary resources (1000-1500ppm). The low content REEs is a challenge for the research community to recover. Different hydrometallurgical techniques including BL have great potential for the recovery of REEs in a low-cost and eco-friendly way [24-27].

Bioleaching of WEEEs

The Waste Electrical and Electronics Equipment’s (WEEEs) are the promising sources of different critical metals like lamp phosphors and magnet swarf. Presently different BL processes have been applied for dissolution of individual metal from WEEEs. However, the knowledge of the individual components must be evaluated in order to develop a process for a mixed WEEE stream. The main challenge is overcoming the dilution effect of the mixed WEEEs containing a variety of contaminants. The microwave leaching or BL have shown promising for leaching of valuable metals from WEEEs [28-31].

Bioleaching of Waste Catalysts

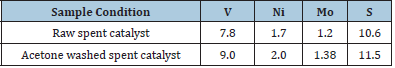

Huge quantity metal catalysts are extensively used in the refinery industries. The catalysts contain different metals such as V,Ni,Mo,Co,Fe, etc to increase the efficiency of different production. They lose their physical properties after several cycles of operation and being discarded as wastes [32-41]. The metal values present in the wastes are very important for the metal industries. The waste catalysts have been categorized into hazardous waste. Therefore, they need some metal reclamation processing followed by the safe disposal. Conventional extractive metallurgy techniques have been used to recover metal values from the waste catalyst. Due to several environmental problems associated with the above traditional methods, BL has shown promising for the metal recovery from the waste catalysts [35,36]. The BL process to recover metals like Ni, V and Mo from a typical waste catalyst of Korean Petroleum Company was conducted [37]. The as procured waste catalysts were washed with acetone using a soxhlet. The composition of the waste before and after acetone wash is listed in Table 1 [12]. Two acidophilic bacteria (iron and sulphur oxidizer) were used for the dissolution of metals values from the waste. Both the acidophiles leached 98.5, 95.6 and 46.2% (w/w) of Ni, V and Mo, respectively.

Table 1: Composition of the spent refinery catalyst in %.

Conclusion

BL is a revolutionary technique to recover metals from their low-grade ores. It offers an economical alternative for the mining industry while high grade ores are being depleted. The process is simple, environmentally friendly, cheaper to operate and maintain when compared to traditional pyrometallurgical processes. A reflection of the great interest in using biological methods for the recovery of metals from waste can be the number of appearing studies. Biological leaching has been conducted in the presence of variety microorganisms and in a wide range of waste-carrying base, special and precious metals. In many cases promising results of metals extraction were obtained. Problems associated with metal toxicity towards microorganisms have been solved by their adaptation to high concentration of heavy metals. Although many problems associated with the selection of the optimum process parameters still remain to be resolved, increased efficiencies of bacterial leaching operations, make these processes more competitive in relation to conventional methods.

Acknowledgement

The authors are grateful to Prof (Dr.) M.R. Nayak, President, Siksha ‘O’ Anusandhan (Deemed to be University), Bhubaneswar for providing infrastructure and encouragement throughout.

References

- Pradhan D, Ahn JG, Kim DJ, Lee SW (2009) Effect of Ni2+, V4+ and Mo6+ concentration on iron oxidation by Acidithiobacillus ferrooxidans. Korean Journal of Chemical Engineering 26(3): 736-741.

- Pradhan D, Kim DJ, Ahn JG, Park KH, Lee SW (2008) Waste recycling through biological route-A Review. Journal of Korean Institute of Resources Recycling 17(2): 3-15.

- Kim DJ, Pradhan D, Park KH, Ahn JG, Lee SW (2008) Effect of pH and temperature on iron oxidation by mesophilic mixed iron oxidizing microflora. Materials Transactions 49(10): 2389-2393.

- Pattanaik A, Sukla LB, Pradhan D, Samal DPK (2020) Microbial mechanism of metal sulfide dissolution. Materials Today Proceedings 30(2): 326-331.

- Pradhan D, Kim DJ, Sukla LB, Pattanaik A, Lee SW (2020) Evaluation of molybdenum recovery from sulfur removed spent catalyst using leaching and solvent extraction. Scientific Reports 10: 1960.

- Pradhan D, Pattanaik A, Samal DPK, Sukla LB, Kim DJ (2020) Recovery of Mo, V and Ni from spent catalyst using leaching and solvent extraction. Materials Today Proceedings 30(2): 322-325.

- Pattanaik A, Sukla LB, Pradhan D (2020) Biological opportunity for beneficiation of low-grade bauxite. Journal of Advanced Microbiology 4(2): 129-136.

- Samal DPK, Sukla LB, Pattanaik A, Pradhan D (2019) Extraction of gold from electronic scraps: A biohydro metallurgical process overview. Biointerface Research in Applied Chemistry 9(5): 4362-4367.

- Sukla LB, Pattanaik A, Pradhan D (2019) Advances in beneficiation of low-grade bauxite. In: Chesonis C (Edt.), Light Metals The Minerals, Metals & Materials Series, Springer-Nature, pp. 3-10.

- Rao KS, Mishra A, Pradhan D, Chaudhury GR, Mohapatra BK, et al. (2008) Percolation bacterial leaching of low-grade chalcopyrite using acidophilic microorganisms. Korean Journal of Chemical Engineering 25: 524-530.

- Pradhan D, Kim DJ, Ahn JG, Gahan CS, Chung HS, et al. (2011) Comparison of bioleaching kinetics of spent catalyst by adapted and unadapted iron oxidizing bacteria-effect of pulp density; particle size; temperature. Korean Journal of Metals and Materials 49(12): 956-966.

- Pradhan D, Patra AK, Kim DJ, Chung HS, Lee SW (2013) A novel sequential process of bioleaching and chemical leaching for dissolving Ni, V, and Mo from spent petroleum refinery catalyst. Hydrometallurgy 131-132: 114-119.

- Pradhan D, Sukla LB, Pattanaik A, Samal DPK, Biswal T, et al. (2021) Improvement in metal dissolution from spent catalyst by adapted Acidithiobacillus ferrooxidans. Biointerface Research in Applied Chemistry 11(1): 7794-7803.

- Pradhan D (2021) Bioleaching of Cu and Zn from complex sulfide using an isolated iron oxidizing bacteria. Letters in Applied Nanobioscience 10(1): 1825-1832.

- Samal DPK, Sukla LB, Pattanaik A, Pradhan D (2020) Mineralization of phosphorous by phosphate solubilizing microbes affects soil properties. Inglomayor 18: 1-9.

- Samal DPK, Sukla LB, Pattanaik A, Pradhan D (2020) Role of microalgae in treatment of acid mine drainage and recovery of valuable metals. Materials Today Proceedings 30(2): 346-350.

- Pattanaik A, Sukla LB, Pradhan D (2019) Bio-beneficiation possibility of low-grade bauxite. International Research Journal of Industrial and Environmental Biotechnology 2(1): 301-325.

- Samal DPK, Sukla LB, Pattanaik A, Pradhan D (2019) Advances in bio-hydrometallurgy: A review. International Research Journal of Industrial and Environmental Biotechnology 2(1): 221-262.

- Pattanaik A, Samal DPK, Sukla LB, Pradhan D (2021) Advancements and use of omic technologies in the field of bioleaching: A review. Biointerface Research in Applied Chemistry 11(3): 10185-10204.

- Pradhan D, Kim DJ, Sukla LB, Pattanaik A, Samal DPK (2019) Bacterial leaching of chalcopyrite concentrates using Acidithiobacillus ferrooxidans. Inglomayor 16: 1-9.

- Sukla LB, Mittal N, Pattanaik A, Pradhan D (2018) Microbial dephosphorization of LD slag. Journal of Sustainable Planet 9(4): 62-69.

- Pattanaik A, Sukla LB, Pradhan D (2018) Applications of genetic engineering in bioleaching. Journal of Sustainable Planet 9(3): 15-25.

- Fagan MA, Sederman AJ, Harrison STL, Johns ML (2013) Phase distribution identification in the column leaching of low-grade ores using MRI. Minerals Engineering 48: 94-99.

- Pradhan D, Panda S, Sukla LB (2018) Recent advances in indium metallurgy: A review. Mineral Processing and Extractive Metallurgy Review 39(3): 167-180.

- Pradhan D, Sukla LB, Kim DJ (2018) Characterization and pretreatment of spent petroleum refinery catalyst for its biodissolution. Inglomayor 14: 2-13.

- Sukla LB, Pradhan D (2017) Microbial leaching of oxidic nickel ore: a review. Journal of Sustainable Planet 8(4): 29-40.

- Sukla LB, Pradhan D, Panda S (2017) Biotechnological utilization of microbes for eco-friendly recovery of metals. Journal of Sustainable Planet 8(2): 16-24.

- Kim DJ, Pradhan D, Chaudhury GR, Ahn JG, Lee SW (2009) Bioleaching of complex sulfides concentrate and correlation of leaching parameters using multivariate data analysis technique. Materials Transactions 50(9): 2318-2322.

- Pradhan D, Pal S, Sukla LB, Chaudhury GR, Das T (2008) Bioleaching of low-grade copper ore using indigenous microorganism. Indian Journal of Chemical Technology 15: 588-592.

- David DJ, Pradhan D, Das T (2008) Evaluation of iron oxidation rate of Acidithiobacillus ferrooxidans in presence of heavy metal ions. Mineral Processing and Extractive Metallurgy 117(1): 56-61.

- Sukla LB, Pattanaik A, Samal DPK, Pradhan D (2021) Microbial leaching for recovery of nickel and cobalt from lateritic ore: A review. In: Anderson C (ed) (2021) Ni-Co. The Minerals, Metals & Materials Series. Springer-Nature, pp. 207-217.

- Kim DJ, Pradhan D, Ahn JG, Lee SW (2010) Enhancement of metals dissolution from spent refinery catalysts using adapted bacteria culture-Effects of pH and Fe(II). Hydrometallurgy 103(1-4): 136-143.

- Pradhan D, Kim DJ, Ahn JG, Chaudhury GR, Lee SW (2010) Kinetics and statistical behavior of metals dissolution from spent petroleum catalyst using acidophilic iron oxidizing bacteria. Journal of Industrial and Engineering Chemistry 16(5): 866-871.

- Pradhan D, Kim DJ, Chaudhury GR, Lee SW (2010) Bio-dissolution of Ni, V and Mo from spent petroleum catalyst using iron oxidizing bacteria. Journal of Environmental Science and Health, Part A 45(4): 476-482.

- Pradhan D, Mishra D, Kim DJ, Chaudhury GR, Lee SW (2009) Dissolution kinetics of spent petroleum catalyst using two different acidophiles. Hydrometallurgy 99(3-4): 157-162.

- Pradhan D, Kim DJ, Baik SB, Lee SW (2011) Extraction of valuable metals from spent desulfurizing catalyst. Journal of Korean Institute of Resources Recycling 20: 48-54.

- Patra AK, Pradhan D, Kim DJ, Ahn JG, Yoon HS (2011) Review on bioleaching of uranium from low-grade ore. Journal of Korean Institute of Resources Recycling 20(2): 30-44.

- Pradhan D, Kim DJ, Ahn JG, Lee SW (2010) Microbial leaching process to recover valuable metals from spent petroleum catalyst using iron oxidizing bacteria. WASET-International Journal of Chemical and Molecular Engineering 4: 232-236.

- Pradhan D, Mishra D, Kim DJ, Ahn JG, Chaudhury GR, et al. (2010) Bioleaching kinetics and multivariate analysis of spent petroleum catalyst dissolution using two acidophiles. Journal of Hazardous Materials 175(1-3): 267-273.

- Pal S, Pradhan D, Das T, Sukla LB, Chaudhury GR (2010) Bioleaching of low-grade uranium ore using Acidithiobacillus ferrooxidans. Indian Journal of Microbiology 50(1): 70-75.

- Pradhan D, Kim DJ, Chaudhury GR, Sohn JS, Lee SW (2010) Dissolution kinetics of complex sulfides using acidophilic microorganisms. Materials Transactions 51(2): 413-419.

© 2021 Pradhan D. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)