- Submissions

Full Text

Aspects in Mining & Mineral Science

Formation of a Park of Dump Trucks for Open Pit Mining

Glebov AV*

Candidate of engineering sciences, Deputy director on scientific questions, Federal state budget establishment the Institute of Mining, Ural branch Russian academy of sciences (IM UB RAS)

*Corresponding author: Glebov Andrey Valerjevich, Candidate of engineering sciences, Deputy director on scientific questions, Federal state budget establishment the Institute of Mining, Ural branch Russian academy of sciences (IM UB RAS), Russia

Submission: July 25, 2019;Published: August 08, 2019

ISSN 2578-0255Volume3 Issue3

Abstract

Principle theses of the methods on forming optimum structure heavy load dump trucks fleet in open pit automobile facilities are adduced. The methods provides calculation of statistic indices of fleet operation according to age groups, standard sizes and to each vehicle within the group; these indices analysis and processing for the purpose of defining weight-average dump truck age; prediction and planning their writing-off according to wear and replenishment the fleet with new, modernized models including.

Keywords: Open pit automobile transport; Transportation; Manufacturing cost; Operation conditions; Dump truck middle age; Optimization the structure of dump truck fleet

Introduction

The imprint parameters of large load-carrying capacity open pit dump trucks (output, annual run, manufacturing cost of rock mass transportation, etc.) vary owing to their wear and on a time basis of their exploitation. Since the fleet of technologic dump trucks in the running open pits truck fleet consists of the cars of different standard size and periods of exploitation, the important and acute problem securing efficient load-trucking is launching up-to-date scientifically grounded methods of forming and sustaining optimal structure of trucks fleet , its renewal, modernization and repair maintenance. The general view of interaction the indices of efficient truck fleet operation (Figure 1) with its structure could be introduced in the form of the scheme [1] where N3 = {N1, N2, …, Nn} – the dump trucks number according to groups of standard size; Q = {Q1, Q2, .., Qn}–the annual volume of rock mass transportation or transport work performed by trucks of each group; {З = З1, З2, …, Зn} – operating costs (expenses) on trucks groups mainte-nance: C = {C1, C2, …, Cn}–specific operating costs (З/Q), or the cost of a transport work unit (1 t-km).

Figure 1:Structure of efficient truck fleet operation

Methods

The operating costs (total and specific) should be determined statistically or by way of calculations both for the trucks fleet at large and for each trucks group and each unit within the group, since such method of approach makes it possible to carry out state analysis of the fleet of different age and type, perform grounded prognosis of its wear renewal or modernization. For this purpose the open pits truck fleet should take accurate stock of each truck operation on a vast group of parameters. The calculation method is expedient to be applied in investigations, that is, for launching long-term strategy of improving and forming the structure of an open pit trucks fleet. Statistic data have spread enough values for dump trucks even of one age group and load-carrying capacity but impartially reflect all the problems connected with technological motor transport exploitation at the plant, the standard of production arrangement and changing prices on material resources including. In connection with this, the statistic method is widely used in trucks fleets for current estimation of each truck state, planning writing off inefficiently operating trucks (as a rule, those, having exhausted self-fatigue life) and purchasing new ones, of other standard sizes and marks including.

The trucks fleet structure should be selected according to two principle criteria:

a) performing the given volume of rock mass transportation or transport work;

b) specific cost of rock mass transportation or transport work secure profitableness of a motor-transport plant.

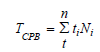

A truck output and a manufacturing cost of rock mass transportation therefore are the functions of the period of its exploitation. In connection with this, the output of trucks operating fleet could be described in the form of a function Q = f(tсрв). The average weight truck age in the feet is determined by the expression:

where: n is the number of trucks age groups; t is the truck age

of i-group, Ni is the number of trucks in i-group; N is the number

of trucks in the fleet. Identically it can be presented that C = f(tсрв),

where C is a specific manufacturing cost of rock mass transportation

or a cost of a transport work unit. Thus, both the above mentioned

criteria can be presented in the form of constraints Q = f(tсрв)≥Q3

and С = f(tсрв)≤Cд, where Q3 is the given annual haulage or transport

work volume, Cд is maximum admissible specific manufacturing

cost of transportation. The output of trucks haulage work and

manufacturing cost are influenced not only by age and standard

size but also by the conditions of trucks operation in an open pit.

Constant open pit depth, haulage distances and extent of hoisting

cause intensive rise of specific transport expenses. Therefore, it is

necessary to use both criteria at a time when planning writing off

wear and purchasing new trucks. This is to be done to sustain average

weight age of trucks in the fleet and compensate the output fall at

the expense of purchasing vehicles of new standard sizes (with due

regard for purchasing price). The admissible manufacturing cost

is by this described by the C point. If the latter is defined by C1>С,

then it is provided with trucks of the t1 average weight age. But in

this case the given Q>Q1 output won’t be performed and the plant is

obliged to secure the trucks t average weight age proceeding from

the given output. If the admissible manufacturing cost of transport

works is C2

The third step is collecting information and determining empiric dependences. As it has been mentioned above, keeping accurate and informative documentation on each truck, standard sizes, and age groups is of paramount importance for regulation current work of open pit motor fleets and accumulation unbiased statistic data for the purpose of analysis, prognosis, planning and forming the optional structure of a motor fleet. The fourth step: In the process of statistic information processing the plots of changing annual specific manufacturing cost of 1 ton rock mass transportation (or the cost of 1 t-km transport work) as well as the output for a definite period of time are constructed. In terms of these plots the empiric dependence between these indices and the years of exploitation is determined, being described by C and Q functions. The fifth step is forming a dump trucks fleet. The fleet can be formed of new vehicles and ones, being in former use, thus the proposed criteria make it possible to regulate once-only capital investments rate as well as to distribute them evenly on a time basis. Besides, it is expedient to forecast a motor-transport fleet for the period not more than 5-7 years. For this period the existing trucks models will be modernized, as well as new ones will be designed having higher load-carrying capacity and with new power units, etc., up-to-date dynamics of science, technique and technology progress indicates this.

Conclusion

The plan of trucks fleet forming, that is, writing off wear and purchasing new ones is laid in terms of tсрв criterion, but having selected the best truck among one-class models according to competitiveness criterion, it cannot be affirmed that it will operate identically efficient in the mining technical conditions of exploitation that are changing as far as an open pit’s depth increases. Besides, every independent truck possesses its reliability indices and service life consequently. In virtue of objective and subjective causes, originating in the process of a dump truck operation in open pits, not each of them is far from exhausting its specific resource with satisfactory technical-economic indices. The question often arises on writing off trucks ahead of time because of poor efficiency of their operation. Thus, for final motor fleet forming it is necessary to calculate economically efficient and technically safety (rational) service life of each dump truck. The methods of approach brought forward in the given article can be employed for fleet forming of extraction-loading equipment and other mining technique.

Halloysite nanotubes typically are natural clay minerals with a unique hollow nanotubular structure includes two-layered aluminosilicate. Hydroxyl groups are a presence at the surface of HNTs, and large pore volume makes them the best candidates for the modification with organic and inorganic materials to enhance loading capacity. Modified halloysite by organosilane seems to be a versatile host for loading several functional guests or functional groups. One of the most effective methods for modified halloysite is to use the dendritic compound. In this mini-review, the various methods of modified halloysite by amine dendritic polymer via convergent and divergent method were investigated. In the divergent method, dendritic amine groups add onto HNTs by the Michael addition of methyl acrylate (MA), and then the amineterminated were grown onto the surface step by step. In the convergent method, the silane groups were replaced by carboxylic groups, and then HNTs-COOH were grown by dendritic materials. In another convergent synthetic method, amine-terminated dendrimers were reacted by HNTs-MA. The result shows that the convergent method has fewer steps than the divergent method, and its results lead to saving cost and energy.

References

- Glebov AV, Karmaev GD (2010) The basic principles of a mining plant automobile fleet forming. Mining Equipment and Electro-Mechanics 7: 37-41.

- Smirnov VP, Lel Yu I (2002) The theory of open pit heavy-load motor transport. Yekaterin burg: UB RAS, Russia. p. 355.

- Kuleshov AA (1980) Powerful shovel-automobile open pit systems, p. 317.

- Glebov AV (2008) The methods of estimation the standards of geotechnique consuming qualities and competitiveness (by the example of open pit dump trucks). Mining Equipment and Electro-Mechanics 5: 49-55.

- Yakovlev VL, Terinburg Y (2001) Estimation standards of geo-technique consuming qualities and competitiveness of open pit dump trucks models for the purpose of choosing the best for the Aihalsky. Mining- Metallurgical Works (MMW) IM UB RAS, Russia. p. 30.

© 2019 Glebov Andrey Valerjevich. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)