- Submissions

Full Text

Annals of Chemical Science Research

Synthesis and Characterization of Chitosan/Hemicellulose Eco-Friendly Film

Yiğit Efe Nas*

Bahçeşehir Science-Technology High School, Hevsel Campus, Turkey

*Corresponding author:Yiğit Efe Nas, Bahçeşehir Science-Technology High School, Hevsel Campus, Diyarbakır, Turkey

Submission: June 19, 2023;Published: July 07, 2023

Volume4 Issue2July , 2023

Abstract

In this study, films were obtained from bio-based polymers using a simple and green method. The films have been prepared by hemicellulose (HC) and chitosan (CN) with glycerol as plasticizer. They were obtained via the solvent-casting method and characterized in terms of structural and thermal properties by Fourier transform infrared spectroscopy (FT-IR) and Thermogravimetric Analysis-Derivative Thermogravimetry Analysis (TGA-DTA) and Differential Scanning Calorimetry (DSC).

Introduction

Packaging is essential for extending food’s shelf life, managing gas exchange and slowing down oxidative reactions. The majority of materials used in packaging today are nonrenewable resources, like petroleum-based polymers, which not only results in resource waste but also poses substantial environmental issues [1].

In 2019, the world produced 360 million tons of plastic, with disposable goods accounting for half of that total. Due to their physicochemical characteristics and commercial viability, synthetic polymers have been used in a number of industries. However, if petroleum-derived polymers are disposed of improperly, their low biodegradability is one of the major causes contributing to the degradation of ecological conditions. To replace or supplement synthetic packaging, there is currently growing interest in using renewable and biodegradable (polysaccharides, lipids, or protein) packaging materials [2]. As a main component of plants, hemicellulose is a renewable, biodegradable and environmental-friendly biomass resource. It is a polysaccharide consisting of five- and six-carbon monosaccharides units, such as xylose, arabinose, glucose, mannose galactose and so on [3].

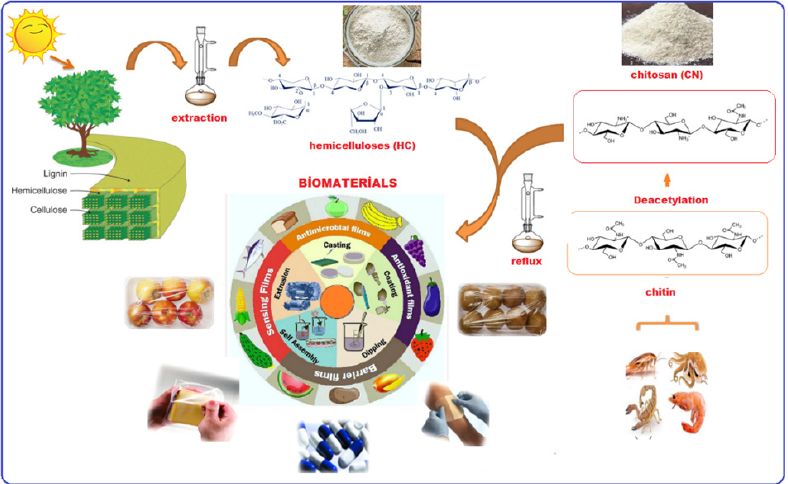

Biobased materials such as hemicellulose, a water-soluble polysaccharide with lower molecular weight from plants and byproducts of pulping industry, have attracted much attention for fruits and vegetables preservation purposes. Hemicellulose-based films exhibit better gas barrier property, especially for oxygen. Meanwhile, hemicellulose could easily combine with other materials due to its small molecular weight [4]. Additionally, it has also been reported that hemicellulose films have strong oxygen barrier qualities that can extend the shelf life of produce and food. However, water absorption originating from the hydroxyl groups of hemicellulose could cause the gas barrier and mechanical properties of hemicellulose materials to drastically deteriorate in a high humidity environment. Many studies are focused on enhancing the hydrophobicity and mechanical properties of hemicellulose film, including chemical modification, in order to overcome these disadvantages and expand the application of hemicellulose in a high humidity environment [3]. Chitin, one of the most abundant natural polymers, can be obtained from exoskeletons of crustaceans and the cell wall of fungi. Its derivate chitosan (CN) offers intrinsic antimicrobial property, non-toxic, biodegradable and outstanding designability properties to be a suitable candidate for the active packaging films [5]. Biobased polymers are ideal materials for replacing petroleum-based polymers due to their renewability, biodegradability and environmental friendliness. Furthermore, hemicelluloses-based films exhibited excellent oxygen barrier property due to their ability to form a dense macromolecular network via the hydrogen bonds, which contributes to the application of hemicelluloses in food-packaging [1]. Scheme 1 shows the obtaining and some applications of hemicellulose and chitosan films. In this paper, the edible film was prepared with hemicellulose and chitosan and characterized by FTIR spectroscopy, TGA-DTA and DSC.

Scheme 1:The obtaining and applications of hemicellulose and chitosan films.

Materials and Methods

Chemicals

Low molecular weight chitosan was purchased from Sigma- Aldrich. Hemicellulose was obtained from a local company in Turkey. Acetic acid (%1) and glycerol were used as solvents and plasticizers, respectively. Purified water was used to prepare the acetic acid solution. They were used without further purification.

Preparation of the films

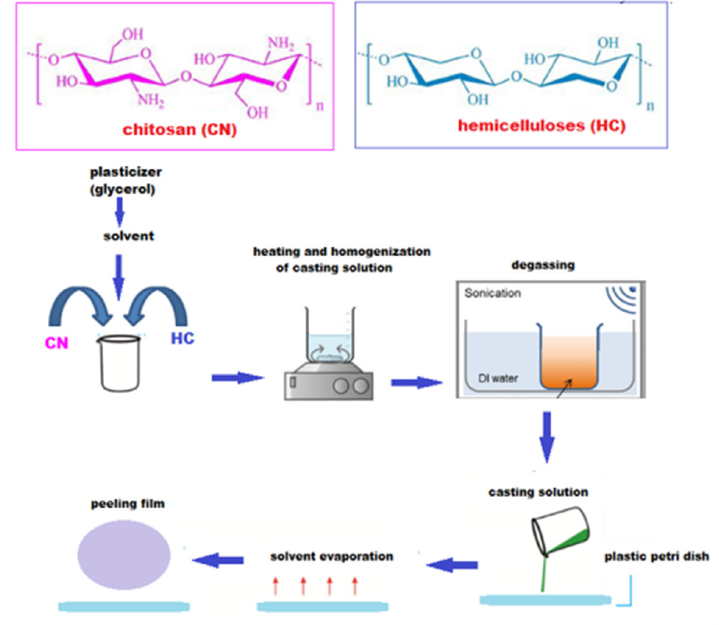

2% (w/v) chitosan solution was prepared in 1% (v/v) of aqueous acetic acid under magnetic stirring at 800 rpm at 40 °C for 2h. 2% (w/v) hemicellulose solution was prepared in 1% (v/v) of aqueous acetic acid under magnetic stirring at 60 °C for 2h until the solids were almost completely dissolved. The obtained solution was degassed using an ultrasound bath (15 minutes, at room temperature). The specified amount of glycerol (30% (w/w) based on the mass of chitosan or hemicellulose) was added to the above solutions as plasticizer. The chitosan and hemicellulose solutions were mixed with the quality ratio of 1:1. The prepared solutions were cast onto acrylic plates and dried at 40 °C for 24h. The dried films were peeled from the casting plates and stored in desiccators [1, 6-8] (Scheme 2).

Scheme 2:Representation of solution cast synthesis of CN/HC film.

Characterization techniques

The CN/HC film was characterized by Fourier transform infrared spectroscopy (FT-IR) and thermogravimetric analysis (TGA) and differential scanning calorimetry (DSC). Infrared spectra of the CN/ HC film were obtained from a Perkin Elmer FT-IR spectrometer equipped with ATR sampling in the range from 4000 to 400cm-1. Thermal study of CN/HC film was conducted using Perkin Elmer Diamond Thermal Analysis. The TGA-DTA measurements were performed between 20 and 400 °C (in N2, 10 °C /min). DSC analyses were carried out between 25 and 300 °C (in N2, 10 °C/min) using a Perkin Elmer Pyris Sapphire DSC.

Results and Discussion

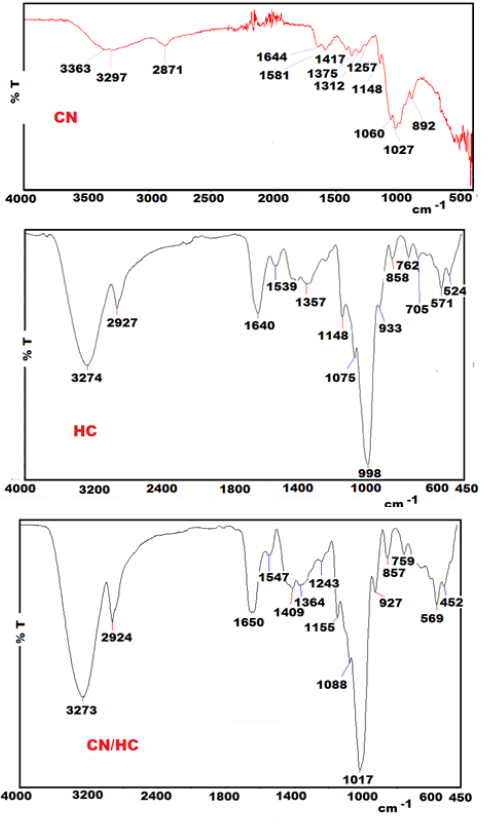

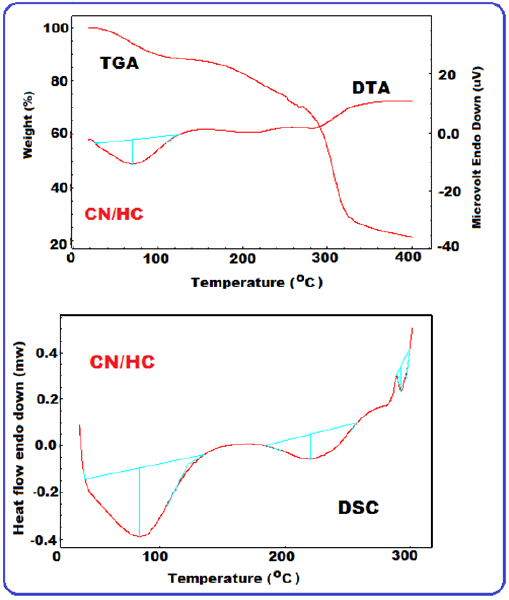

Figure 1 shows FT-IR spectra of the chitosan (CN), hemicellulose (HC) and CN/HC film. The chemical structure of CN/HC film was approved from FT-IR. The spectrum of CN exhibits a broad peak at 3363cm-1 attributed to O–H and N–H stretching, 2871cm-1 for aliphatic C–H stretching, 1644cm-1 for C–O stretching of amide I band, 1581cm-1 for N–H stretching of amide II band, 1257cm-1 for amide III band, 1148cm-1 for asymmetric stretching of C-O-C groups, 1060-1030cm-1 for C–O stretching of the C-OH groups and 892cm-1 for CH2 bending of the saccharide structure, which are in agreement with previously reported data [1,9]. The peak at 1640cm-1 is originated from -COO of hemicelluloses. The signals at 1075 and the broad peak at 3374cm-1 are related to C–O–C stretching vibration and with the –OH stretching, respectively [1,8]. The C–O–C stretching vibration of the film was broadened and shifted to 1088cm-1, owing to the overlap of the ether bond in both hemicelluloses and chitosan. This indicated that the hemicellulose and chitosan were miscible due to the strong hydrogen bonds and electrostatic interactions between the polymer chains [1]. The TGA–DTA and DSC curves of the CN/HC film are given in Figure 2. The initial degradation temperatures (Ton) of CN, HC (powder) and CN/HC have been found to be 270, 65 and 70 °C, respectively. Furthermore, temperature values weight losses of 20% (T20) and 50% (T50) were determined 279, 200 and 220 °C and 335, 300 and 315 °C for CN, HC (powder) and CN/HC respectively. Tg (glass transition temperature-softening temperature) of the HC (powder) and CN/HC are calculated from their DSC curve and found as 73 and 81 °C. CN/HC film is thermally more stable than raw hemicellulose due to the strong hydrogen bonds and electrostatic interactions between the hemicelluloses and chitosan [1].

Figure 1:FT-IR spectra of chitosan, hemicellulose and CN/HC film.

Figure 2:TGA-DTA and DSC curves of the CN/HC film.

Conclusion

The plasticized chitosan/ hemicelluloses edible films were successfully prepared in this work. The bio-based packaging films can be used as alternative eco-friendly materials to reduce the impact of synthetic or non-biodegradable plastics on the environment.

Acknowledgements

The author is thankful to thank Dicle University, Faculty of Science, Department of Chemistry (Diyarbakır of Turkey) for experimental studies. This study was conducted under the consultancy of by Associate Professor Hatice KARAER YAĞMUR. The author thanks her for her contribution.

References

- Jiyuan X, Ruirui X, Lu Z, Tongqi Y, Runcang S (2019) Plasticized hemicelluloses/chitosan-based edible films reinforced by cellulose nanofiber with enhanced mechanical properties. Carbohydrate Polymers 224: 115164.

- Lucio M, Carmen C, Ricardo P (2020) Effect of glycerol and sorbitol concentrations on mechanical, optical, and barrier properties of sweet potato starch film. NFS Journal 20: 1–9.

- Tingyao L, Renfeng Z, Yuxin L, Xinliang Z, Kai L, et al. (2022) Effect of the high barrier and hydrophobic hemicellulose/montmorillonite film on postharvest quality of fresh green asparagus. Industrial Crops & Products 187:115509.

- Zeshan T, Renfeng Z, Yuxin L, Jiasai X, Xinliang Z, et al. (2021) Hemicellulose-based nanocomposites coating delays lignification of green asparagus by introducing AKD as a hydrophobic modifier. Renewable Energy 178: 1097-1105.

- Zhengguo W, Xiujie H, Yi-Chen L, Hanzhen X, Xiaoying W (2018) Novel chitosan films with laponite immobilized Ag nanoparticles for active food packaging. Carbohydrate Polymers 199: 210–218.

- Yuxin L, Bing S, Zhongliang W, Yonghao N (2016) Mechanical and water vapor barrier properties of bagasse hemicellulose-based films. Bio Resources 11(2): 4226-4236.

- María E Castelló, Pablo S Anbinder, Javier I Amalvy, Pablo J (2018) Production and characterization of chitosan and glycerol-chitosan films. Materials Research Society 3: 3601-3610.

- Ying G, Xian Ming Q, Ge Gu C, Feng P, Run Cang S (2016) Facile approach to prepare drug-loading film from hemicelluloses and chitosan. Carbohydrate Polymers 153: 542-548.

- Joydeep D, Nirmla D (2021) Preparation, optimization and characterization of chitosan-sepiolite nanocomposite films for wound healing. International Journal of Biological Macromolecules 186: 244-254.

© 2023 Yiğit Efe Nas. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)