- Submissions

Full Text

Annals of Chemical Science Research

The Film Random Laser Doped with Core-Shell Structure Ag Spheres

Songtao Li1,2*, Min Zhao1,2, Yuwei Wang1,2 and Zhi Ren1,2

1Department of Mathematics and Physics, North China Electric Power University, China

2Heibei Key Laboratory of Physics and Energy Technology, North China Electric Power University, China

*Corresponding author:Songtao Li, Department of Mathematics and Physics and Heibei Key Laboratory of Physics and Energy Technology, North China Electric Power University, Baoding, 071003, China

Submission: April 05, 2023;Published: April 12, 2023

Volume3 Issue5April , 2023

Abstract

A chemical reduction method is employed to fabricate the core-shell structure Ag spheres. The ink of Rhodamine 6G, Polyvinyl Alcohol and Ag spheres is spin coated on a silicone slab, and the film random laser doped with core-shell structure Ag spheres is fabricated after solidification. The Ag spheres are employed as scattering particles, and the film of R6G and PVA work as active material layer. Irradiated by the pump beam, the random laser emission is with the threshold of about 12.55mJ/cm2. This reduction method is a cheap way to fabricate Ag spheres and benefits the applications of random lasers.

Keywords:Ag sphere; Reduction; Random laser

Introduction

Lawandy et al. [1] reported the lasing emission in strongly scattering media in 1994 and random lasers have been studied wildly in the world. The merits of random lasers, such as miniature in volume and simplicity in structures [2-4], attract the researchers to design and fabricate many types of random lasers. The semiconductor nanoparticles [5], conjugated polymer films [6], organic dye-doped gel films [7], metal nanoparticles or nanostructures [8-10] are introduced into the new-type random laser. The nanoparticles of Ag and Au are commonly reported [11]. However, silver or gold is a kind of noble metal and expensive. In this work, a reduction method is employed to fabricate the core-shell structure Ag spheres and the Ag spheres made by a cheap way provide a scattering mechanism in the film random laser.

Fabrication

The silica sphere with the mean diameter of 150μm is weighed 0.25g and blended with 1.5ml AgNO3 water solution of 3% mass concentration in a beaker. And then the 3% silver ammonia solution is titrated until the solution in the beaker is clear. 2ml glucose solution with 5% concentration is added and the beaker is water-bathe heating for 2 minutes. The reduced Ag nanoparticles deposit on the surface of silica spheres. Thus, the silica sphere is core and the Ag layer is shell. The Ag sphere with core-shell structure is fabricated. The Polyvinyl Alcohol (PVA) is dissolved in water at the concentration of 40mg/ml and the Rhodamine 6G (R6G) is dissolved in the PVA solution at the mass-volume ratio of 3mg: 1ml. The spheres with coreshell structure are blended with the R6G PVA solution at the mass-volume ratio of 0.4mg: 1ml. Final the ink contains the spheres with core-shell structure, R6G, PVA and water. The ink is spin coated at the rotating speed of 500r/min for 60s on a silicone slab with a dimension of 15mm*15mm. A film random laser is fabricated after water is removed in a drying box at room temperature.

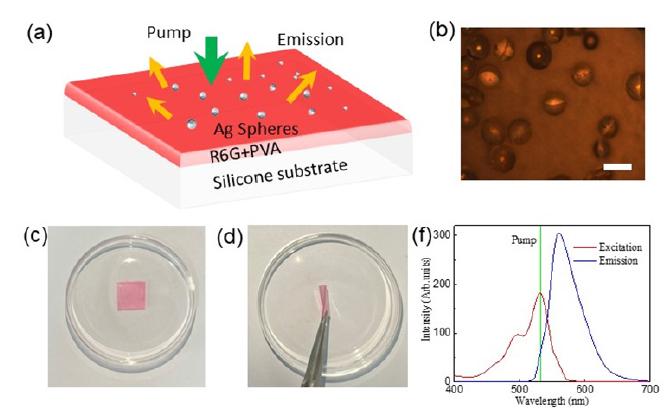

The diagram of the film random laser is shown in Figure 1(a). PVA works as film-forming agent and the R6G is active material. The core-shell structure Ag spheres disperse in the active material layer of R6G and PVA. Figure 1(b) shows the optical micrograph of core- shell structure Ag spheres. Some Ag spheres disperse in the active material layer of 200μm. The front view and the side view of the sample are demonstrated in Figure 1(c & d). The excitation and the emission of R6G are measured by a Fluorescence spectrometer (Hitachi, F7100) and plotted in Figure 1(f). The pump beam of 532nm is just in the absorbance band, benefiting R6G emission.

Figure 1:(a)The diagram of the film random laser; (b) the optical micrograph of core-shell structure Ag spheres; (c) and (d) the front view and the side view of the sample, respectively. (f) the excitation and the emission of R6G. The white scale bar denotes 200μm.

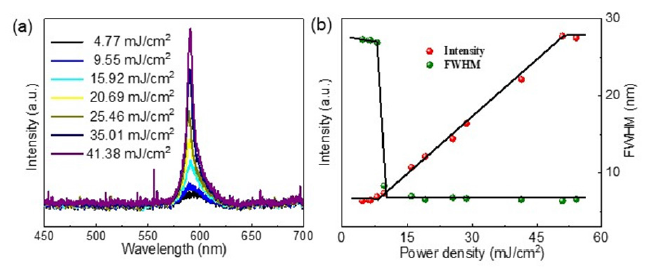

The film random laser is pumped by a frequency-doubled neodymium-doped yttrium aluminum garnet (Nd: YAG) pulsed laser, with a wavelength of 532nm, 30-ns laser pulses at a repetition rate of 10Hz and with pulse energy up to 50mJ. The Spectra of the random laser emissions is centered at approximately 590nm, with a fullwidth at half maximum (FWHM) of about 6nm. In Figure 2, the pump beam directly irradiates the sample and the emission is collected by a spectrometer (Maya 2000 Pro, Ocean Optics). The intensity of the output laser as a function of the pump power density, indicating a pump threshold of about of 12.55mJ/cm². The pump threshold of film random laser with Ag spheres is about of 12.55mJ/cm2, lower than 18.2mJ/cm² which is the pump threshold of film random laser without Ag spheres. So, the Ag sphere works as scatter particles, and reduces the pump threshold.

Figure 2:The Spectra of the random laser emissions at various pump power densities. (b) The intensity of the output lasing and FWHM as a function of the pump power density, indicating a pump threshold of about 12.55mJ/ cm2.

Conclusion

A chemical reduction reaction is employed to decompose AgNO3 and Ag deposits on silica spheres. The Ag layer is deposited on the surface of silica spheres; thus, the core-shell structure Ag spheres are fabricated. This method is a cheap way to fabricate the Ag spheres. The film random laser doped with core-shell structure Ag spheres is fabricated by a spin coating method and a drying process. The random laser emission is with the threshold of about 12.55mJ/cm2. This reduction method is a cheap way to fabricate Ag spheres and benefits the applications of random lasers.

References

- Lawandy NM, Balachandran RM, Gomes ASL, Sauvain E (1994) Laser action in strongly scattering media. Nature 368(6478): 436-438.

- Wiersma D (2008) The physics and applications of random lasers. Nat Phys 4(5): 359-367.

- Wiersma DS, Cavalieri S (2001) Light emission: A temperature-tunable random laser. Nature 414(6865): 708-709.

- Vanneste C, Sebbah P, Cao H (2007) Lasing with resonant feedback in weakly scattering random systems. Phy Rev Lett 98(14): 143902.

- Cao H, Zhao YG, Ho ST, Seeling EW, Wang QH, et al. (1999) Random laser action in semiconductor powder. Phys Rev Lett 82(11): 2278-2281.

- Frolov SV, Gellerman W, Ozaki M, Yoshino K, Vardeny ZV (1997) Cooperative emission in pi-conjugated polymer thin films. Phys Rev Lett 78(4): 729-732.

- Meng X, Fujita K, Zong Y, Murai S, Tanaka K (2008) Random lasers with coherent feedback from highly transparent polymer films embedded with silver nanoparticles. Appl Phys Lett 92(20): 201112.

- Heydari E, Flehr R, Stumpe J (2013) Influence of spacer layer on enhancement of nano-plasmon-assisted random lasing. Appl Phys Lett 102(13): 133110.

- Zhai T, Zhang X, Pang Z, Su X, Liu H, et al. (2011) Random laser based on waveguided plasmonic gain channels. Nano Lett 11(10): 4295-4298.

- Meng X, Fujita K, Moriguchi Y, Zong Y, Tanaka K (2013) Metal-dielectric core-shell nanoparticles: Advanced plasmonic architectures towards multiple control of random lasers. Adv Opt Mater 1(8): 573-580.

- Wang Y, Shi X, Sun Y, Zheng R, Wei S, et al. (2014) Cascade-pumped random lasers with coherent emission formed by Ag-Au porous nanowires. Opt Lett 39(1): 5-8.

© 2023 Songtao Li. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)