- Submissions

Full Text

Annals of Chemical Science Research

Experimental Evaluation of Physical Characteristics of Nano Crude Oil with the Aim of Enhanced Oil Recovery

Haniyeh Zare1, Mehdi Bosaghzadeh1 and Frshad Farahbod2,*

1Department of Chemical Engineering, Esfarayen university of technology, Iran

2Department of Chemical Engineering, Firoozabad Branch, Islamic Azad University, Iran

*Corresponding author:Frshad Farahbod, Department of Chemical Engineering, Firoozabad Branch, Islamic Azad University, Iran

Submission: October 19, 2022;Published: November 02, 2022

Volume3 Issue2November , 2022

Abstract

The choice of operating conditions in the oil industry depends on the characteristics of the processed and produced oil. Knowledge of the fluid flow of oil at different pressures and temperatures is essential for the construction of appropriate equipment as well as process management. This is especially important for a new type of oil that contains nanoparticles. The laboratory results show that a small increase in the number of nanoparticles has a positive effect on the amount of thermal diffusivity coefficient. In addition, the integration of nanoparticles with crude oil increases the kinetic capacity of molecules. Also, increasing the volume percentage of nanoparticles added to light and heavy crude oil from 0.0 to 0.8 leads to an average increase of 7.6% in the electrical conductivity coefficient of the oil. The results show that the heat capacity of light and heavy crude oil varies from 4256 to 4457 J/kg. C and 4476 to 5002 J/kg. C, respectively. Moreover, the heat capacity of light and heavy nano-oils is changing from about 4285 to 4496 J/kg. C and 4494 to 5021 J/kg. C, respectively.

Keywords: Crude oil; Thermoelectric; Kinetic properties; Nanoparticles; Dimensional numbers

Introduction

The need for oil has been a major factor in many of the wars of the twentieth century, including World War II. During these wars, oil facilities, which were one of the most important and strategic assets, were heavily bombed. The German invasion of the Soviet Union was aimed at capturing Baku’s oil fields. Because it could provide more needed oil resources for the besieged German army. Oil exploration in North America in the early twentieth century led to the United States becoming a major oil producer in the mid-twentieth century. Although US oil production peaked in the 1960s, the Saudi Arabia and the Soviet Union surpassed the United States in oil production. Today, about 90% of the fuel needs of vehicles are met by oil. The oil also accounts for 40 percent of total energy consumption in the United States. But it is only responsible for providing 1% of its electricity generation. The oil, as a portable and dense source of energy, provides the fuel needed by most vehicles. In addition, oil is the base and raw material of many industrial chemicals. Therefore, it is considered one of the most important goods in the world. Russia, Saudi Arabia and the United States are the top three oil producers. In recent years, the development and advancement of micro-technologies has led to the manufacture and equipment’s production on a micro and nano scale that is used in various industries. The use of nanoparticles as a surface enhancer can also improve the performance of cooling and heating systems. Due to the more stable nature of nano compared to its pioneer generation (including micro and millimeter particles) as well as its extremely high thermal conductivity, nanoparticles can significantly increase the heat transfer coefficient in different cases. The results show that when the amount of thermal energy is much higher than the momentum energy, the coefficient of friction will depend on the concentration of nanoparticles. Also, the heat transfer of nanofluid in channels has attracted the attention of many researchers due to its promising applications. Numerically, the researchers showed that constant heat flux boundary conditions can be used to analyze heat and fluid flow in microfluidic systems. Also, the Nusselt number correlation for the fully developed laminar flow is extended as a function of two dimensionless parameters, including the byte number and the relative conductivity. The American Petroleum Institute classifies fluids based on their rheological behavior. Accordingly, all fluids are classified as Newtonian or non-Newtonian fluids. Fluid mechanics will also study the forces involved in both static and flowing fluids. Hence fluid flow theory is often well established. While the fully developed slow current is still theoretically achieved, a current with other properties, such as turbulent flow, must rely on laboratory and experimental relationships. It should be noted that all the fluid flow in the pipe has a zero-velocity profile in the pipe wall, due to the non-slip condition to the maximum in the center of the pipe. Therefore, in this research, nanotechnology has been used to investigate the thermoelectric properties of high- and low-density oils.

Materials and Method

API grade of crude oil

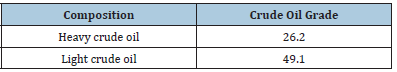

The feed used in this research is two types of light and heavy crude oil. The American standard grade of crude oil used in this study is classified according to the Table 1.

Table 1:The composition of crude oil

Properties of zinc oxide

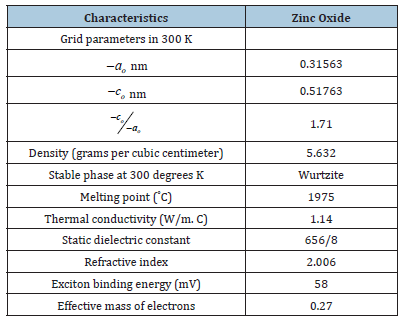

The Zinc oxide nanoparticles have been used in this work due to their wide and varied applications. The Zinc is an essential mineral that is non-toxic in low concentrations. The data show a good relationship between health and appropriate concentrations of zinc oxide compounds (Table 2).

Table 2:Physical properties of zinc oxide.

Method of preparation of zinc oxide nanoparticles

The Zinc metal is used to make a solution containing one molar of Zn2+. Therefore, first the Zn2+ solution is purified, then a type of 0.05M active surfactant, as well as approximately 10% ethanol, is mixed with the Zn2+ solution under ultrasonic conditions. The produced solution is shaken at regular intervals, regularly. Then, the same reactants are mixed with a molar solution of sodium carbonate under similar conditions. The two produced aqueous solutions are mixed, proportionally. The reconstituted solution is shaken under ultrasonic conditions for half an hour [1-4]. Then, another active surfactant is added to the resulting solution and mixed again for half an hour. The resulting solution is then filtered and rinsed several times with pure water and ethanol under ultrasonic conditions, alternately. Finally, the synthesized material is dried for 50 minutes at 80 °C.

Laboratory equipment

The laboratory equipment includes a mixer tank, adiabatic test tube, and electric heater, which has been used to investigate the thermoelectric behavior of light and heavy crude oil. At the first, the crude oil is mixed with zinc oxide nanoparticles in an ultrasonic device (400 W and 180 min.) [5-9]. Then, heavy and light crude nano-oil is mixed in a mixing tank and then passed through an electric heater until the temperature reaches the range of 30 to 84 degrees Celsius. The digital sensors installed on the set-up transmit the obtained parameters to the control box. Finally, nano crude oil is collected in a tank. All variables are obtained for one type of crude oil and then the whole set is drained and washed by water flow injection.

Results and Discussion

The experiments were performed to investigate the thermoelectric properties and behavior of light and heavy nanooil compared to simple crude oil. In this study, thermo-physical properties such as: electrical conductivity, density, viscosity, thermal conductivity, thermal diffusivity and specific heat were investigated.

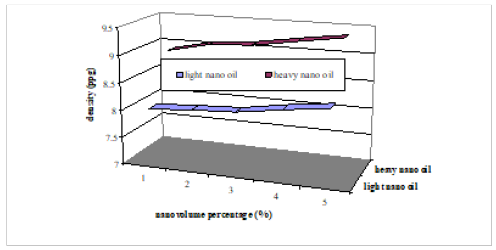

The effect of nanoparticle volume percentage on density

The effect of adding zinc nano oxide on the density value is shown in the Figure 1. Increasing the volume percentage of nanoparticles increases the amount of density. Results show, the accumulated mass per unit volume increases. Changes in the volume percentages of nanoparticles from 1 to 5 percent increase the density from 8 to 8.34lb/gallon for light oil and also from 8.9 to 9.36lb/gallon for heavy nano oil. The experimental results show that the average increase in density with the addition of zinc oxide nanoparticles is about 9.6% [10-14].

Figure 1:Effect of nanoparticle volume percentage on nano-oil density.

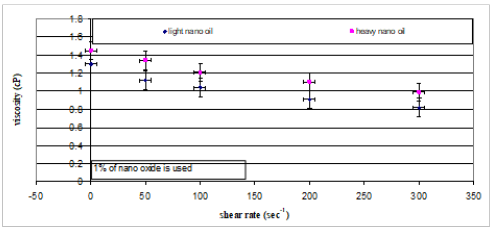

Investigation of the viscosity of nano-oil

The Figure 2 shows the dynamic viscosity value against the shear rate. Increasing the shear rate reduces the amount of dynamic viscosity for both nano-oil samples. The shear rate varies from 0.0 to 300 (1/s) and the dynamic viscosity varies from 1.3 to 0.82cP for light nano-oil and 1.45 to 0.99cP for heavy nano-oil. The experiments show that increasing the shear rate reduces the dynamic viscosity by an average of about 28%. In addition, the decrease in the amount of dynamic viscosity may be related to the interaction between oil and nanoparticles [15-17].

Figure 2:Relationship between shear rate and viscosity of nano-oil.

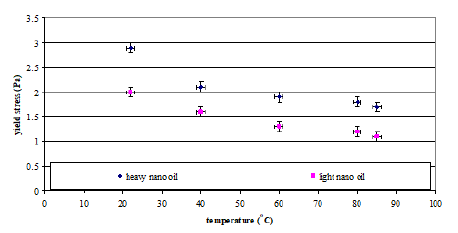

Investigation of nanofluid yield stress

The Figure 3 shows the relationship between temperature and yield stress. The laboratory results show that yield stress decreases with increasing temperature from 22 °C to 85 °C. The yield stress change is 1.1 to 2 Pa for light nano-oil and 1.7 to 2.9 Pa for heavy nano-oil. Two experimental relationships are expressed to predict the yield stress in terms of operating temperature. The regression of these two empirical relationships is close to one. Hence, the accuracy of the curves is very good. Operational data indicate that the average difference between the yield stress of light and heavy nano oil is 39.6%.

Figure 3: Effect of temperature on nano-field yield stress.

The relationship between yield stress and nano volume percentage is shown in the Figure 4. The results show that this correlation is positive. These changes and differences are identified for heavy and light nano-oils and the regressions are presented in this figure. The average difference between the two curves is 25.2%, approximately. The regression of the first curve defined for heavy nano oil is equal to 0.95464 and the regression of the second curve which is related to light nano oil is equal to 0.9408.

Figure 4:Effect of nanoparticle volume percentage on yield stress.

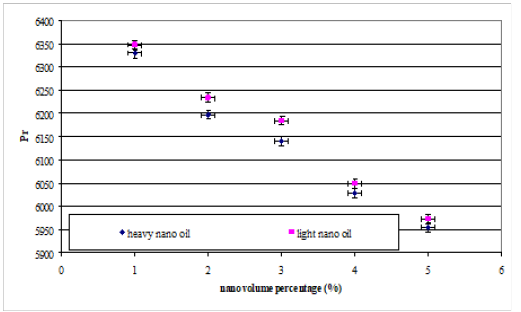

Investigation of Prandtl number for heavy and light nano oil

The change in Prandtl number in terms of volume percentage changes of nanoparticles is shown in the Figure 5. The obtained results in this figure show that the trend of both curves for light and heavy nano-oil is decreasing and can be predicted by logarithmic function. The proposed curve regression is 0.931 for light nano oil and 0.9654 for heavy nano oil. The changes in the Prandtl number value for both heavy and light nano-oils are shown in the figure above. Laboratory data show that sometimes a decrease in the amount of Prantel may be observed in both light and heavy nanooils. Experiments show that the addition of nano-zinc oxide reduces the amount of Prandel. Also, the average deviation between Prantel number values in ordinary crude oil and nano oil is about 0.85%.

Figure 5: Effect of nanoparticle volume percentage on nanoparticle Prandtl number..

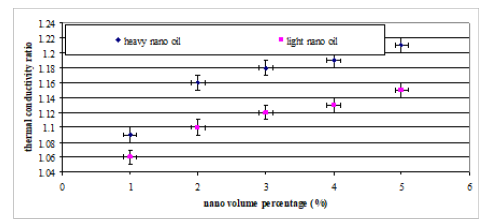

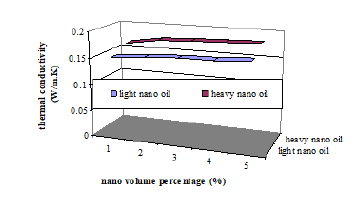

Investigation of thermal conductivity and thermal diffusivity

The change in the thermal conductivity ratio of light and heavy nano oils versus the volume percentage of nano is shown in the Figure 6. The experimental data show that the thermal conductivity ratio is greater than one. It means that the ratio of thermal conductivity values for light and heavy nano-oil is improved. This ratio is 0.1 to 1.15 for light nano oil and 1.09 to 1.21 for heavy nano oil. Results illustrate the average difference between the values of the two curves is approximately 5.2%.

Figure 6: Effect of nanoparticle volume percentage on thermal conductivity ratio

The Figure 7 shows the effect of adding zinc oxide nanoparticles on the amount of thermal conductivity with temperature change. In this experiment, the volume percentage of nanoparticles varies from 1 to 5. The studies show that increasing the volume percentage of nanoparticles usually increases the energy transfer capacity of materials. Therefore, it increases the thermal conductivity from 0.15 to 0.164 W/m2K for light nano-oil and 0.165 to 0.182 W/ m2K for heavy nano-oil. Increasing the volume percentage of nanoparticles shows a similar increasing effect on the thermal conductivity of nano-oil. The presence of zinc nano-oxide as a metal nano-oxide as well as the presence of free electrons in metal particles increases the kinetic energy of light and heavy nano-oil, which is well shown in the above diagram. The studies show that the use of nanoparticles increases the thermal conductivity by an average of about 9%.

Figure 7: The effect of volume percentage of nanoparticles on the amount of thermal conductivity.

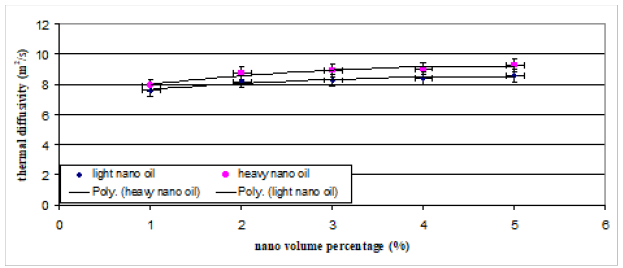

Investigation of thermal diffusivity of heavy and light nano oil

The thermal diffusivity ratios for light and heavy nano-oils are 1.07 to 1.25 and 1.03 to 1.16, respectively. The experimental results show that the thermal diffusivity ratio in 1 to 2% by volume of nanoparticles is increasing sharply and this ratio in 2 to 5% by volume of nanoparticles is almost constant and linear. The Figure 8 shows the relationship between the ratios of thermal diffusivity to the volume percentage of nanoparticles.

Figure 8:The effect of nanoparticle volume percentage on the thermal diffusivity ratio of nano-oil.

The Figure 9 shows the effect of the volume percentage of nanoparticles on the amount of thermal diffusivity. An increasing trend in the amount of thermal diffusivity has been obtained for both nano-oil samples. This behavior is predictable according to the definition of the quantity of thermal diffusivity. The results show that changes in the volume percentage of nanoparticles have a positive effect on the amount of thermal conductivity and a negative effect on density and heat capacity. Therefore, increasing the number of nanoparticles has a positive effect on the amount of thermal diffusivity.

Figure 9:Effect of nanoparticle volume percentage on thermal diffusivity.

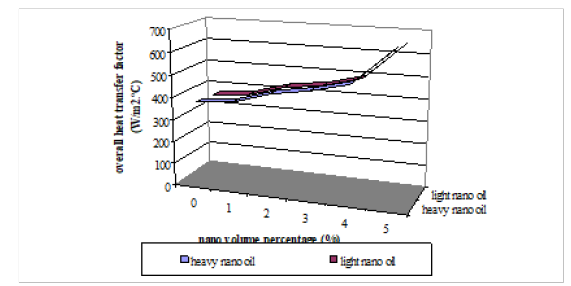

Investigation of overall heat transfer coefficient

The overall heat transfer coefficient is measured in Figure 10. Both defined functions to express the overall heat transfer behavior are exponential. Also, the regression of two curves for light nano oil and heavy nano oil is 0.9056 and 0.9248, respectively. Operational data show that with increasing volume of nanoparticles, the kinetic ability of fluid molecules also increases.

Figure 10:Effect of nanoparticle volume percentage on thermal diffusivity.

In this study, the use of nano zinc oxide in oil has been investigated. The effect of adding nanoparticles with different weight percentages to the oil stream has been investigated, experimentally. In this work, some important thermoelectric and physical properties of light and heavy nano-oil have been measured. In addition, some dimensionless groups usable in hydrodynamics and heat transfer calculations are presented. Also, the effect of geometric conditions and number of nanoparticles on dimensionless groups and physical thermal properties of crude oil has been investigated. Finally, the following results are obtained: increasing the volume percentage of nanoparticles added to light and heavy crude oil from 0.0 to 0.8 leads to an average increase of 7.6% in the electrical conductivity coefficient of the oil. The results show that the heat capacity of light and heavy crude oil varies from 4256 to 4457 J/kg. C and 4476 to 5002 J/kg. C, respectively. Moreover, the heat capacity of light and heavy nano-oils is changing from about 4285 to 4496 J/kg. C and 4494 to 5021 J/kg. C, respectively.

The experimental results show that the thermal diffusivity ratio in 1 to 2% by volume of nanoparticles is increasing sharply and this ratio in 2 to 5% by volume of nanoparticles is almost constant and linear. The studies show that increasing the volume percentage of nanoparticles usually increases the energy transfer capacity of materials. Therefore, it increases the thermal conductivity from 0.15 to 0.164 W/m2K for light nano-oil and 0.165 to 0.182 W/m2K for heavy nano-oil. The laboratory results show that yield stress decreases with increasing temperature from 22 °C to 85 °C. The yield stress change is 1.1 to 2 Pa for light nano-oil and 1.7 to 2.9 Pa for heavy nano-oil. The shear rate varies from 0.0 to 300 (1/s) and the dynamic viscosity varies from 1.3 to 0.82cP for light nanooil and 1.45 to 0.99cP for heavy nano-oil. The experiments show that increasing the shear rate reduces the dynamic viscosity by an average of about 28%.

<References

- Zhou Cuihong, Wang Yanying, Huang Xintong, Wu Yupeng, Chen Jiarui (2020) Optimization of ultrasonic-assisted oxidative desulfurization of gasoline and crude oil. Chemical Engineering and Processing-Process Intensification 147: 107789.

- Riyahin M, Montazeri GM, Jamoosian L, Farahbod F (2014) PVT-generated correlations of heavy oil properties. Petroleum science and technology 32(6): 703-711.

- Farahbod F, Farahmand S (2017) Introduction of novel process for sweetening of sour crude oil: Optimization of process, Journal of Energy Resources Technology 139(2): 022907.

- Alheety Mustafa A, Al-Jibori Subhi A, Karadağ Ahmet, Akbaş Hüseyin, Ahmed Mukhtar H (2019) A novel synthesis of MnO2, nanoflowers as an efficient heterogeneous catalyst for oxidative desulfurization of thiophenes. Nano-Structures & Nano-Objects 20: 100392.

- Ghaderi A, Abbasi S, Farahbod F (2018) Synthesis, characterization and photocatalytic performance of modified ZnO nanoparticles with SnO2 Materials Research Express 5(6): 065908.

- Abbas Mohammmed Nsaif, Ibrahim Suha Answer (2019) Catalytic and thermal desulfurization of light naphtha fraction. Journal of King Saud University-Engineering Sciences 32(4): 229-235.

- Farahbod F, Farahmand S (2015) Experimental and theoretical study of fluidized bed for SO2 recovery as sulfur from effluent gases from sulfur production unit. Fuel 156: 103-109.

- Sinhmar Pankaj S, Gogate Parag R (2019) Ultrasound assisted oxidative deep-desulfurization of dimethyl disulphide from simulated turpentine. Ultrasonics Sonochemistry 63: 104925.

- Kazerooni MRM, Farahbod F (2016) Experimental investigation of Sulphur removal from LPG: new aspect. Journal of Environmental Science and Technology 9(1): 164-169.

- Fadhil Mustafa H, Ammar Saad H, Abdul Jabbar Marwa F (2019) Microwave-assisted catalytic oxidative desulfurization of gasoil fuel using synthesized CuO-ZnO nanocomposites. Journal of Fuel Chemistry and Technology 47(9): 1075-1082.

- Zhou Jing (2018) Adaptive PI control of bottom hole pressure during oil well drilling. IFAC-Papers Online 51(4): 166-171.

- Ojinnaka Marcellinus A, Beaman Joseph J (2018) Full-course drilling model for well monitoring and stochastic estimation of kick. Journal of Petroleum Science and Engineering 166: 33-43.

- Junttila Juho, Dijkstra Noortje, Aagaard-Sørensen Steffen (2018) Spreading of drill shearings and sediment recovery of three exploration wells of different ages, SW Barents Sea, Norway. Marine Pollution Bulletin 135: 224-238.

- Hu Song, Han Hengda, Syed-Hassan Syed Shatir A, Zhang Yani, Wang Yi, et al. (2018) Evolution of heavy components during sewage sludge pyrolysis: A study using an electrospray ionization Fourier transform ion cyclotron resonance mass spectrometry. Fuel Processing Technology 175: 97-103.

- Lindsay Gordon, Hay John, Glen Norman, Shariatipour Seyed (2018) Profiling and trending of coriolis meter secondary process value drift due to ambient temperature fluctuations. Flow Measurement and Instrumentation 59: 225-232.

- Loyola-Fuentes José, Jobson Megan, Smith Robin (2019) Fouling modelling in crude oil heat exchanger networks using data reconciliation and estimation of unmeasured process variables. Computer Aided Chemical Engineering 46: 1033-1038.

- Loyola-Fuentes José, Smith Robin (2019) Data reconciliation and gross error detection in crude oil pre-heat trains undergoing shell-side and tube-side fouling deposition. Energy 183: 368-384.

© 2022 Frshad Farahbod. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)