- Submissions

Full Text

Annals of Chemical Science Research

Trends on the Mechanical and the Optical Properties of Papers Affected by the Inorganic Additives Determined by Ash on Ignition at 900 °C and a Thermodynamic Model Applied for their Tensile Strength

Chryssou Κ*, Stassinopoulou M and Lampi E

General Chemical State Laboratory, Β΄ Chemical, Greece

*Corresponding author:Chryssou Κ, General Chemical State Laboratory, Β΄ Chemical, Greece

Submission: March 30, 2021;Published: April 19, 2021

Volume2 Issue3April, 2021

Abstract

The extremely rapid increase in the use of A4 and A3 photocopiers and printers in recent years and some printing problems observed in them make it imperative to continue and intensify the controls carried out on copy paper samples by the General Chemical State Laboratory in Greece. Samples of photocopy papers were brought to the laboratory and their mechanical and optical properties were tested. The construction of technical specifications in collaboration with other bodies of the public sector will continue to achieve effective protection of the public and private sectors, and of the consumer public in general. Action should be taken to inform those involved in the production, import and marketing of photocopier paper and the consumer in particular about the requirements of the appropriate technical specifications and the potential risks of using unsuitable paper in modern laser printers.

Keywords: Tensile strength; Ash on ignition at 900 °C; Pick picking IGT; CIE whiteness; Inorganic additives; Public sector

Introduction

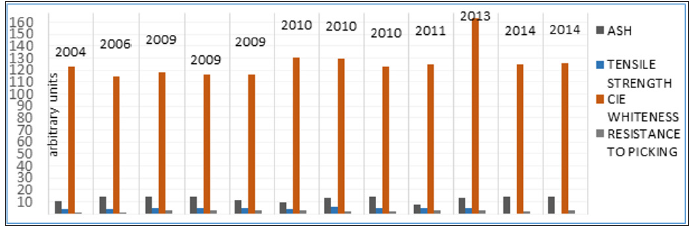

A series of samples of photocopy papers A4 and A3 were brought to the GCSL from both the public and private sectors. The percent (%w/w) ash content on ignition [1] for these papers was determined during the whole year 2018. Then, the same samples were tested for their tensile strength [2] and the pick picking of the paper by an IGT tester [3], as well as for their CIE whiteness values [4,5] (Figure 1). The tensile strength, tearing resistance and folding of a paper are improved with cationic starch, or with resins of wet strength. Increased content of filling matter leads to inferior strength of the raw material of paper, but it helps to the transfer of the pigment coating to the raw material. Pigment is the major component of a pigment coating. The principal pigment is kaolin, sometimes referred to as china clay. Other pigments include calcium carbonate, titanium dioxide, aluminum trihydrate, amorphous silicas and silicates, talc, zinc oxide, barium sulfate and plastic pigments [6,7] & (Table 1). Analyses carried out in the past years from 2004 -2014, on photocopy papers A4 and A3, have shown that a trend was followed, to a better tensile strength, and better pick picking of the paper, as well as a high CIE whiteness value, accompanied to a high %w/w ash content. This trend was not followed only for the pick picking of the paper, between years 2004-2014 (Figure 2).

Figure 1: Graphical representation of the parameters tested ash, tensile strength, CIE whiteness, resistance to pick picking for the year 2018.

Figure 2: Graphical representation of the parameters tested on the paper samples, such as ash on ignition, tensile strength, CIE whiteness, and printability, for years 2004-2014.

Table 1: The values of the parameters of the percent ash on ignition, the corresponding values of the tensile strength, CIE whiteness, and printability of the paper, for the 46 samples tested during the year 2018.

For the year 2018, the trend was not followed for the tensile strength of the paper samples but was followed for the pick picking of the papers and their whiteness value, to actually increase their value as the ash content increased. For the analyses carried out during 2018, it was found that the tensile strength of the paper samples tested was depended more on the intermolecular bonding forces and the strength of the fibers of the papers than the inorganic additives. This means that the higher tensile strength was because mainly of the effect of hydrogen bonding. Generally, the amount and quality of the bonds of the paper fibers are important and affect the tensile strength. The essence of the hydrogen bond in cellulose is that the adjacent hydroxyl groups have a strong attraction for each other which may reach 5kcal/mole. Thus, a bond of fibers of high level is required to forbid the disruption or the parting of the fibers during the printing of the paper which is the final result of the paper’s use. The tensile strength is a combination of factors such as the flexibility, the bonding strength and the fiber strength. These factors are dependent on the type of fibers of the paper, the length and thickness of the fibers, the pattern of the fiber network, the number of bonds, and the strength of the individual bonds [8-10].

A thermodynamic model for the tensile strength measurement of the papers tested in the laboratory

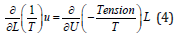

A thermodynamic formalism then can be presented here by consideration of the physical properties of a paper band or better a paper strip used in the testing of its tensile strength. Let us suppose that we are building a descriptive model for the properties of the paper band used in the testing of the tensile strength. The paper band consists of a bundle of long-chain paper fibers. The quantities here of the macroscopic interest are the length L, the tension T, the temperature T, and the energy U of the paper strip. The length L plays a role analogous to the volume V (L ~ V), while the tension T plays a role analogous to the negative pressure (T~-P) (1). The main component of paper is a cellulose polymer. Cellulose is an organic compound with the formula (C6H10O5) n a polysaccharide consisting of a linear chain of several hundreds to many thousands of β (1→4) linkage D-glucose units. Αn analogue then of the mole number can be associated with the number of glycose monomer units in the paper band. That number is not generally variable and it can be taken here as a constant. A qualitative representation of the experimental observation can be summarized in two properties: First, at constant length the tension T increases with the temperature T. Second, the energy is observed to be essentially independent of the length, at least for lengths shorter than the “elastic limit” of the paper strip, a length corresponding to the straightening of the glucose (polymer) chains. The simplest representation of the latter observation can be represented by the following equation:

Where, c is a constant and Lo is the unstretched length of the paper strip.

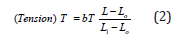

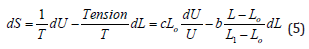

The linearity of the length with tensile tension between the unstretched length Lo and the elastic limit length L1, can be represented by the following equation:

Where, Lo < L < L1, and b is a constant.

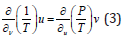

The insertion of the factor T of the temperature in this equation (rather than T2) is dictated by the thermodynamic condition of consistency of the two equations of state. That is as in the equation:

Where, u and υ are the molar quantities of the energy U and the volume V respectively.

In an analogous way, the following equation can be derived:

Which dictates the linear factor T in equation (2).

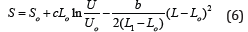

Then we can derive the following equation:

Where, S is the entropy of one glucose polymer chain and the fundamental equation may be written, after integration of the molar equation as,

This fundamental equation (6) is constructed on the basis of the qualitative of information, and it can represent the empirical properties reasonably. This model of the paper strip or the paper band illustrates the manner in which thermodynamics can guide us towards an elementary model building.

Conclusion

The above study showed that there must be more controls, and tests in the laboratory, for the photocopy papers sold in the market. Also, notification to all the parts involved in the chain of importing and trade of paper, as well as to the consumers, to comply with the quality technical standards already set, and the dangers involved with the use of papers which do not actually conform to them.

References

- ISO 2144-2015: Paper, board and pulps - Determination of residue (ash) on ignition at 900 °C.

- ISO 1924-2/2008: Paper and board-Determination of tensile properties–Part 2: Constant rate of elongation method (20mm/min).

- ISO 3783-2006: Paper and board-Determination of resistance to picking-Accelerated speed method using the IGT-type tester (electric model).

- ASTM E313-10: Standard practice for calculating yellowness and whiteness indices from instrumentally measured color coordinates.

- ISO 11476/2000: Paper and board –Determination of CIE whiteness, C/2° (indoor illumination conditions).

- Fardim P (2000) Paper and surface chemistry part 2-coating and printability. Institute of Quimica: 1-13.

- Fardim P (2000) Paper and surface chemistry part 1-fiber surface and wet end chemistry. Institute of Quimica: 1-14.

- Pulp and Paper, Chemistry and Chemical Technology, In: Casey JP(Ed.), 3rd (edn), Volumes 2-4.

- Murray SG (1996) Dyes and fluorescent whitening agents for paper. Paper Chemistry, Chapman & Hall, pp. 161-193.

- Kauffman GB (1981) Advanced inorganic chemistry; A comprehensive text. In: Cotton FS, Wilkinson G(Eds.), 4th (edn), John Wiley & Sons.

© 2021 Chryssou Κ. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)