- Submissions

Full Text

Annals of Chemical Science Research

Challenges and Accomplishments of TD-NMR in Industry 4.0

Martelozo CD and Alberto CL*

Department of Embrapa Instrumentação, Brazil

*Corresponding author: Alberto CL, Department of Embrapa Instrumentação, Brazil

Submission: March 25, 2019;Published: March27, 2019

ISSN : 2688-8394 Volume1 Issue2

Opinion

Nuclear magnetic resonance (NMR) is a spectroscopic and imaging technique used in chemistry, physics, biology, medicine, agriculture and in food, biotechnology, pharmaceutical, petroleum and polymer science and technology. The application of NMR can be divided in three great areas: magnetic resonance imaging (MRI) that is widely used in medical diagnostic, highresolution NMR spectroscopy (HR-NMR) that is a powerful method to determine structure and dynamic from small molecules to large molecules, such as proteins and nuclei acids. Both MRI and HR-NMR are based on heavy, bulk and high field superconducting magnets and the instruments are expensive and have to be installed in a controlled environment. The third class of NMR instruments is known as low field NMR or low-resolution NMR or more precise time domain NMR (TD-NMR).

The TD-NMR instrument is based on small, light and low field (>0.7T) permanent magnet, much cheaper the MRI or HR-NMR instruments and are less demanding in controlled environment and therefore can be used not only in laboratories but also in factories floor [1]. TD-NMR methods have been used as alternative to time consuming, laborious wet chemical methods. The main advantages of TD-NMR analysis are high velocity, minimum sample preparation, non-solvent or chemical waste, non-destructive and minimum dependence on analyst. Therefore, it has been used for quality control in industries and now, the method has been providing also real time process control, what comes straight to the Industry 4.0 goal [2]. The 4.0 industry was proposed in 2011 at the Hannover messes fair an initiative sponsored and encouraged by the German government in association with technological companies, universities and research centres. It calls for the complete decentralization of the control of productive processes and a proliferation of intelligent interconnected devices throughout the production and logistics chain.

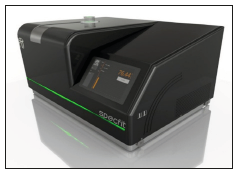

The nine pillars of Industry 4.0 are: Internet of Things (IoT), big data, cloud computing, cybersecurity, autonomous robots, system integration, augmented reality, simulation, additive manufacturing (3D printing). TD-NMR is related with at least 6 of those pillars and we will use the palm oil extraction industry as example of it. The equipment Spec FIT Palm Oil [Figure 1], developed in partnership between the NMR company Fine Instrument Technology and Embrian (Brazilian Corporation for Agricultural Research) is dedicated to measure oil content in the feedstock (bunches and fruits), in by-products, residues and the final products. Most of the measurements is performed in less than one minute and the analyses, in the process line, takes approximately 15 minutes, depending of the company process. Therefore, the measurements are fast enough for tuning the equipment’s during the processing (online). For example, if the TD-NMR analysis of fibres, obtained after the pressing process shows 12% of oil and a tuned press is capable to remove the oil down to 7%, this means the untuned press results in 5% of loss. For a press extractor that process 15 tons of palm fruits per hour, this means a huge loss. Before the TD-NMR analysis, the oil content in the fibres was determined by wet chemical method based on solvent extraction using Soxhlet equipment. This measurement is performed in several steps, requiring sample preparation, extraction with solvent for several hours, evaporation of solvent and weight of the extracted oil. Furthermore, the accuracy of method is strong dependent on the analyst. However, the major problem is that the results comes hour after processing and large amount of palm oil have been discarded in the fibre. Therefore, with fast NMR results, the press can be rapidly tuned, avoiding losses, enhancing efficiency and consequently, more palm oil can be produced from the same amount of feedstock. The sample manipulation for NMR analysis can be easily automated by robots and the results can be uploaded in the cloud and integrated with intelligent extractor machines to obtain the maximum yield. The digital TD-NMR data can also provide the efficiency history of the company yield, and if linked with data like palm oil price, can be related with the financial company history. So, the manager can use the data for a lot of important parameters of the company performance. In this example, we have Internet of Things (IoT), big data, cloud computing, cybersecurity, autonomous robots and system integration. Prove enough that TD-NMR is an important tool for Palm Oil Industry 4.0.

Figure 1:TD-NMR equipment spec FIT palm oil..

Similar TD-NMR application can be used in others industry. In polymer industry the TD-NMR methods can be used to measure the oil content in processed fibres (spin finish), the polymerization reaction to measure the unreacted monomers, the polymer crystallinity; In pharmaceutical and cosmetic industries it has been used to measured moisture and fat content, fluorine content in toothpaste, the presence of polymorphism in solid drugs; in food industry TD-NMR has been used to measure the moisture and oil content, oil drop size in emulsion such as mayonnaise and salad dressing, solid fat content (SFC) in margarine and butter; in petroleum industry the hydrogen content in fuel, the porosity in reservoir rocks, oil viscosity; in agriculture it has been used to measure the oil content and oil quality in seeds, sugar content in fruits, fat content in raw and processed meat, moisture content in soils, adulteration of vegetable oil among many other applications.

The applications of NMR are a fast-growing area and many new methods and applications have been published each year. Therefore TD-NMR application is open new opportunities for process control in many industries helping automatic and quality control and quality assurance. However, these revolution in analytical and automation process are not always welcome. Even with all those advantages, it is not easy to convince the user that TD-NMR is better or has the same level of accuracy as the reference method. Comparison between the results are not always as expected or because the reference method has no accuracy, or because there is no parameter to compare. Simple question as: “what is the method’s standard deviation” or “what is the method’s repeatability” has no answer leading to blind comparisons. Recently, chemometrics has showing itself as a powerful tool helping on this question with mathematics results proving that the correlation is good or not, but even a good correlation sometimes is not enough to the user with no scientific arguments [3]. The last resource in that case is to develop validate and certificated methods. A good example is the solid fat content (SFC) measuring using NMR that replaced completely the dilatometry technique. SFC is a quality parameter for oil and fats products directly related with the final product in food industry like margarine, chocolate, ice cream etc. The curve generated by SFC in different temperature called solid curves and represents the melting profile of the material. This interferes straight to the tasty and texture of the final product. Because of that, almost all industries that produce or use oil and fat as raw material has an NMR in the quality control lab. For that, Bruker, the developer of the technique, had a hard work to develop what is today an AOCS [4], ISO, IUPAC and others recognized normative and now NMR is synonymous of solid curve or SFC. In any way, convincement requires time and effort that goes far beyond scientific problems, but this in not only TD-NMR challenge, it is a step of innovation process. SFC was probably the first innovation process using TD-NMR and palm oil one of the most recently, but not last. The manufactures have to be always updated in tendency and combining it efforts with science leads to beautiful innovations like TD-NMR in Industry 4.0.

References

- Colnago LA, Fabiana DA, André AA, Rodrigo BVA, Allan AL, et al. (2014) Why is inline NMR rarely used as industrial sensor? challenges and opportunities. Chemical Engineering Technology 37(2): 191-203.

- https://www.forbes.com/sites/bernardmarr/2018/09/02/ wh a t - i s - i n d u s t r y- 4 - 0 - h e re s - a - s u p e r - e a sy- ex p l a n a t i o n - fo r - anyone/#36cf62959788

- Geladi P (1992) Herman wold, the father of PLS. Chemometrics and Intelligent Laboratory Systems 15(1): 7-8.

- (2017) AOCS Official Method Cd 16b-93. Solid Fat Content (SFC) by Low- Resolution Nuclear Magnetic Resonance, Direct Method.

© 2019 Alberto CL. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)