- Submissions

Full Text

Advancements in Civil Engineering & Technology

Hydraulic Efficiency and Economic Efficiency of Pumps

Zohrab Samani*

Professor of Civil Engineering, NMSU, Las Cruces, USA

*Corresponding author:Zohrab Samani, Professor of Civil Engineering, NMSU, Las Cruces, USA

Submission: January 24, 2024;Published: February 01, 2024

ISSN: 2639-0574 Volume6 Issue1

Opinion

In water resource related industry, pumps are used to deliver water from one point to another or to create pressure in a water system. Typically, an engineer designs a system to deliver a certain amount of water from one source to another. The next step is to select a pump to deliver that amount of water with the highest pump efficiency. The problem with this approach is that what shows up as pump efficiency is really hydraulic efficiency and not economic efficiency. A pump with high hydraulic efficiency is not necessarily the best choice. What really matters in the end is how much it costs to get the water from a source to a destination. Hydraulic efficiency is different than economic efficiency.

Economic Efficiency

Economic efficiency (ECE) is defined as the amount of water pumped to a system per unit amount of energy used in the process.

The economic efficiency (ECE) can be calculated using the following methodology:

Volume of water pumped = Q2*T (1)

In which:

Q2= Outflow from the pump which is equal to inflow to the system.

T= Duration of pumping

The amount of energy used by the pump the above-described volume of water is:

Energy = (Q1*H)/(E*T) (2)

Where:

Q1= Inflow to the pump which is the discharge rate at which the pump is operating

H= Operating head

E= pumping efficiency

The economic efficiency (ECE) can therefore be calculated as: ECE = (Q1*T)/(Q2*H/E*T) = (Q1/Q2)*(E/H) (3)

Where the inflow to the pump (Q1) is the same as the outflow (Q2), then ECE can be defined as: ECE= E/H (4)

The energy used per unit of water pumped can be calculated as: Energy per unit of water pumped = l/ECE (5)

Using the concept of economic efficiency, one could easily evaluate the economic advantage or disadvantage of alternative design options.

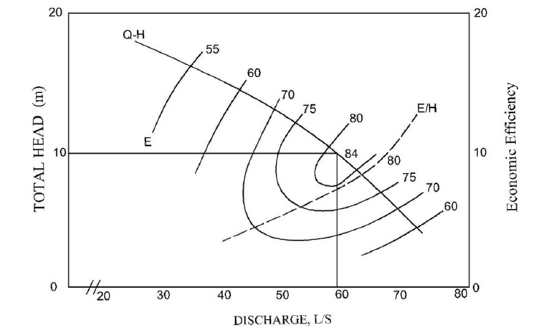

Hydraulic Efficiency and Economical Efficiency of a centrifugal pump is shown in Figure

In Figure 1 shown below, the pump characteristic curves are shown along with pump efficiency and economic efficiency. A typical designer may think that this pump should be operating at discharge rate of 60 L/s, and efficiency of 84 percent. However, from an economic point of view, it is better for this pump to operate on the right side of the hydraulic efficiency. In fact, the further away from the peak efficiency, the better.

Figure 1:Hydraulic Efficiency and Economical Efficiency of a centrifugal pump.

Economic Efficiency in a Municipal Water Distribution System

The concept of economic efficiency may be of significance in municipal water systems with well pump stations in the distribution system, which does not have off-peak energy rates. Normally these pump stations for primary production are designed for hydraulic operating conditions that satisfy peak day demand, but in practice the pump is actually operating against a dynamic demand system. In such a system, the sequence of pump operation should arrange such that the pumps with highest ECE turns on first and if the demand is not met, the second to highest ECE should be turned on, In practice however the pump with smallest discharge rate is turned on followed by the second smallest discharge rate and this practice result in higher energy cost for the municipality.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)