- Submissions

Full Text

Advancements in Civil Engineering & Technology

Feasibility Study of Using Thermally Modified Silica-Manganese Slag as Coarse Aggregates in Concrete

Pengfei Wu1,2,4, Xiaoyan Huang3, Junhong Mo4, Pingfeng Fu1,2 and Wen Ni1,2*

1School of Civil and Resource Engineering, University of Science and Technology Beijing, China

2Key Laboratory of the Ministry of Education of China for High-efficient Mining and Safety of Metal Mines, University of Science and Technology Beijing, China

3Beike Yunhong Environmental Technology (Beijing) Co., Ltd, China

4Ningxia Jiyuan Juntai New Material Technology Co., LTD, China

*Corresponding author:Wen Ni, School of Civil and Resource Engineering, University of Science and Technology Beijing and Key Laboratory of the Ministry of Education of China for High-efficient Mining and Safety of Metal Mines, University of Science and Technology Beijing, China.

Submission: March 20, 2023;Published: April 11, 2023

ISSN: 2639-0574 Volume5 Issue4

Abstract

This paper reports the results of using thermally modified silica-manganese slag (TMSS) as coarse aggregates in concrete. The results showed that TMSS is composed of crystalline minerals after thermal modification. The leaching concentration of heavy metals in TMSS is lower than the index limit specified for drinking water sources, indicating that TMSS is environmentally safe to use in concrete. The TMSS coarse aggregate has excellent physical and mechanical properties, and its performance indicators meet the requirements of Chinese national standard. The fluidity and compressive strength of concrete prepared with TMSSCA are comparable to those with natural gravel aggregate.

Keywords:Thermally modified; Silica-manganese slag; Coarse aggregate; Concrete

Introduction

Silica-manganese slag(SS) is a by-product of smelting manganese silicon alloy and 1.2 tons of manganese silicon slag will be generated for every 1ton of manganese silicon alloy produced. The annual discharge of SS in China is about 10 million tons, almost all of which are in a stockpiled state. The massive storage of SS poses a serious threat to the surrounding ecological environment [1]. How to realize the resource utilization of SS is an urgent problem to be solved for the sustainable development of the silicon manganese alloy industry.

The use of SS as concrete aggregate has a promising application prospect. Water quenched SS has fine particles and cannot be used as aggregate in ordinary concrete. Relevant literatures [2-3] has reported the study of using air-cooled SS as coarse aggregate for concrete. Wong KS et al. [2] found that SS has weak adhesion to cement hydration products and the use of SS as aggregate reduces the compressive and tensile strength of concrete by 9.2% and 17.5%, respectively. Patil AV et al. [3] studied the use of air-cooled SS as coarse aggregate for road concrete. The results showed that the sharp edges and corners of the crushed air-cooled SS cannot ensure the smoothness of road concrete after plastering. Due to the high content of glass phase, the surface of air-cooled SS after crushing is smooth and can be sharp, so it is not suitable for direct use as aggregate for concrete.

In this paper, the feasibility of using thermally modified SS (TMSS) as coarse aggregate for concrete was preliminarily studied. SS was modified by slow cooling process and its mineral composition and environmental safety were studied. Basic characteristics of TMSS coarse aggregate (TMSSCA) were studied and the workability and mechanical properties of TMSSCA concrete and natural coarse aggravate (NCA) concrete were compared.

Materials and Experimental Procedures

Raw materials

The hot melt silicon manganese slag is taken from the slag outlet of a smelting furnace of a ferroalloy company. The raw materials used in the preparation of concrete include cement, ASTM Class F fly ash, fine aggregate, coarse aggregate, poly-carboxylic acid superplasticizer and water. Cement is an ordinary Portland cement (OPC) with a strength grade of 42.5N. Fine aggregate is natural sand with a fineness modulus of 2.6. Coarse aggregate includes NCA and TMSSCA with a continuous grading of 5-20mm.

Experimental procedures

The hot melt SS was directly transferred from the slag outlet of the smelting furnace to a cast iron slag ladle preheated to 800 ℃ and was kept for 24 hours in the cast iron slag ladle. Subsequently, the SS was taken out of the cast iron slag ladle and naturally cooled to obtain TMSS. TMSSCA with a grading of 5-20mm was prepared by crushing and sieving process. The mineral composition of TMSS was characterized by X-ray diffraction (XRD). Leaching solution of TMSS was prepared in accordance with the Chinese environmental protection industry standard [4] and concentration of heavy metal ions in the leaching solution was detected by inductively coupled plasma-mass spectrometry. Physical and mechanical properties of TMSSCA were characterized according to Chinese national standard [5].

Raw materials were well mixed according to the mixture proportions. The fresh concrete was caste into molds(100 mm × 100 mm × 100 mm) after slump test. All specimens were demolded after 24h of casting and then cured in a moisture room at 20 ± 2 C and 90 ± 2% relative humidity (RH) until 3 days, 7 days and 28 days. Three specimens at each age were used for compressive strength by a testing machine at a loading rate of 6 kN/s.

Mixture proportions

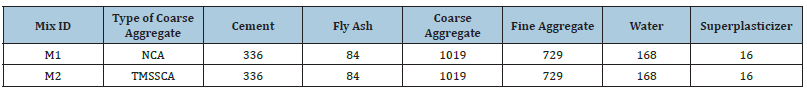

Table 1 shows the mixture proportions of concrete investigated in this study. Mixture M1 and M1 were prepared with NCA and TMSSCA as coarse aggregate respectively.

Table 1:Mixture proportions of concrete (kg/m3).

Results and Discussion

Characteristics of TMSS

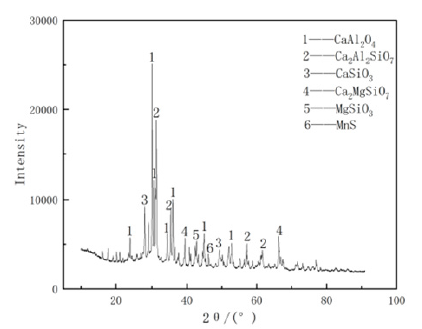

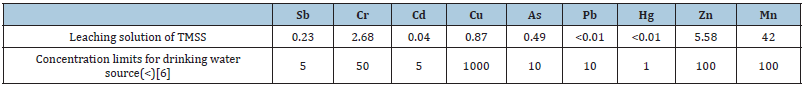

XRD pattern of TMSS is given in Figure 1. As shown in Figure 1, The TMSS is mainly composed of crystalline mineral phases, including CaAl2O4, Ca2Al2SiO7, CaSiO3, Ca2MgSiO7, MgSiO3, MnS, etc. The detection results of heavy metal concentration in the leaching solution of TMSS are shown in Table 2. From Table 2, it can be seen that the concentration of heavy metals in the leaching solution of TMSS is lower than the limit for drink water source specified in the national standard [4]. The results show that the TMSS will not cause heavy metal leaching hazards and is environmentally safe.

Figure 1:XRD pattern of TMSS.

Table 2:Detection results of heavy metal concentration in the leaching solution of TMSS (10-3mg/L).

Characteristics of TMSSCA

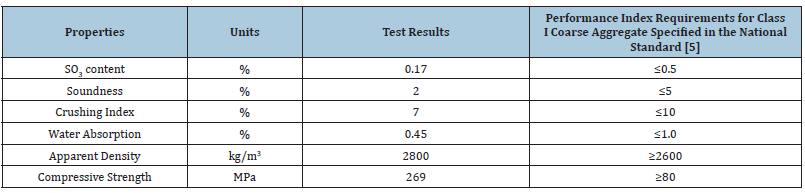

Test results of properties including SO3 content, soundness, crushing index, water absorption, apparent density, compressive strength of TMSSCA and performance index requirements for Class I coarse aggregate specified in Chinese national standard [5] were shown in Table 3. As shown in Table 3, properties of TMSSCA examined in this study are superior to requirements specified in Chinese national standard [5]. The compressive strength of TMSSCA reaches 269MPa, which is far higher than the standard requirement of 80MPa. Thus, the results showed that TMSSCA is suitable for using as coarse aggregates in concrete.

Table 3:Test results of properties of TMSSCA.

Concrete with TMSSCA

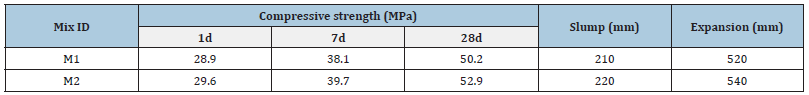

Test results of workability and compressive strength of concrete respectively using TMSSCA and NCA as coarse aggregates are shown in Table 4. As can be seen from Table 4, under the same mix ratio, the slump and expansion of TMSSCA concrete slurry are greater than those of NCA concrete slurry. This is mainly due to the fact that the surface water absorption of TMSSCA aggregate is lower than that of natural crushed stone aggregate, thereby improving the fluidity of fresh concrete. The compressive strength of TMSSCA concrete at various ages is slightly higher than that of NCA concrete. Therefore, the use of TMSSCA to prepare concrete with workability and compressive strength comparable to those of concrete prepared with NCA is demonstrated.

Table 4:Workability and compressive strength of concrete.

Conclusion

The feasibility of using TMSS to prepare coarse aggregate has been preliminarily confirmed in this paper. The hot-melt SS can be modified by slow cooling to adjust its phase to crystalline mineral phase. The leaching concentration of heavy metals from TMSS is lower than the limit value specified for drinking water sources, indicating its environmental safety. TMSSCA shows excellent properties including SO3 content, soundness, crushing index, water absorption, apparent density and compressive strength. The fluidity and compressive strength of concrete prepared with TMSSCA can be comparable to that of NCA concrete. This study shows the potential use of SS, while further study are still needed to investigate the influence of incorporating TMSSCA on the durability of concrete.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgement

The authors wish to express their gratitude to the funding supplied by the National Key Research and Development Program of China [grant number 2020YFC1807804].

References

- Liu Q, Li J, Lu Z, Li X, Jiang J, et al. (2022) Silicomanganese slag: Hydration mechanism and leaching behavior of heavy metal ions. Construction and Building Materials 326: 126857.

- Ting MZY, Wong KS, Rahman ME, Joo MS (2020) Mechanical and durability performance of marine sand and seawater concrete incorporating silicomanganese slag as coarse aggregate. Construction and Building Materials 254: 119195.

- Patil AV, Pande AM (2011) Behaviour of silico manganese slag manufactured aggregate as material for road and rail track construction. Advanced Materials Research 255: 3258-3262.

- HJ 557 (2010) Solid waste. Extraction procedure for leaching toxicity. Horizontal vibration method.

- GB/T 14685 (2022) Pebble and crushed stone for construction.

© 2023 Wen Ni. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)