- Submissions

Full Text

Advancements in Civil Engineering & Technology

The Engineering Study on the Use of Crushed Stone Aggregate and Crusher Dust Mixes in Flexible Pavements of Karachi-Hyderabad Motorway, Sindh, Pakistan

Pathan MA1* and Pathan MM2

1CP & A Geology University of Sindh Jamshoro, Pakistan

2Department of Environmental Engineering & Management, Pakistan

*Corresponding author: Mushtaque Ahmed Pathan, CP & A Geology University of Sindh Jamshoro, Pakistan

Submission: November 25, 2019;Published: February 18, 2020

ISSN: 2639-0574 Volume4 Issue1

Abstract

The development of the country is directly related with the better road communication from mega cities to rural villages. Pakistan is a developing country and has started a grand network of highways, superhighways and motorways in all four provinces along with Kashmir and Northern and northwestern regions bordering china and Afghanistan. Highway Flexible pavements are the most commonly used form of pavements and have four component layers namely Sub-grade, Sub-base and base and surface courses, which are constructed of materials like natural soils, sand, morrum etc., are considered to be costly in terms of construction as well as maintenance. The result of plastic fine sand their sticky characteristics in natural soils hampered the performance of the pavement. To reduce the impact of failures alternative materials are to be investigated. In this connection an attempt is made by using Crushed Stone Aggregate and Crusher Dust as road component materials. Gradation mixes were prepared to meet the specifications of National Highway Authority Pakistan and subjected for various geo-technical characterizations such as gradation, compaction, strength etc. According to the results of strength values of compacted crusher dust and Crushed Stone mixes have been evaluated through a series of CBR tests by varying the crusher dust and sand contents from 10% to 60%. On the other hand, the suitability of compacted crusher dust as a road base and sub-base materials have been verified in accordance with N H A P specifications and findings that 20-30% in place of sand can satisfy the materials used as sub-base and base courses [1-3].

Keywords: Pavement; Highway; Void ratio; CBR; Construction

Introduction

The National Highway Authority (NHA) was created, in 1991, through an Act of the

Parliament, for planning, development, operation, repair and maintenance of National

Highways and Strategic Roads specially handed over to NHA by the Federal Government or by

a Provincial Government or other authority concerned [4]. NHA is custodian of 39 national

highways/motorways/expressway/strategic routes having a total length of 12,131kms. This

is 4.6% of total national road network i.e. 263,775kms, however, it carries and covers 80%

of commercial traffic and N-5 which is bloodline of Pakistan, carries 65% of this load in the

country. Being custodian of Highway assets of Pakistan’s road network, NHA is committed to

provide safe, modern and efficient transportation system. It has been proved as the backbone

of Highway network (Countrywide Motorway Network Map), National Highways functions as

the backbone of Pakistan’s transportation system, plays an important role in the development

of micro and macro economy and also developed the national integration by increasing the

social and economic dependence among the Provinces [5].

The overall performance of a pavement reflects the proper functioning of the consecutive

component layers of a road pavement. The design model, life of the pavement, durability and

maintenance cost can be explained by the selection of materials and their characterization. In

the construction of highways major component layers are Sub-base, Base courses and their

functions are directly reflecting the function of Sub-grades. Before this natural soil, sands,

gravel material and Morrum can be frequently used as sub-base materials. The presence of

plastic fines and their sticky characteristics hampered the performance of the pavements due to its imbibition’s of moistures and yields continuous plastic strains.

To avoid these component layers, reduce thrust on sub-grade and

to improve the drainage performance of the sub-base course and

durability of the pavement as a whole alternative material like

crusher dust fly ash pond ash etc, can be studied. In this study an

attempt has been made for the utilization of mechanically stabilized

crushed stone and crusher dust mixes as sub-base and base courses

[6].

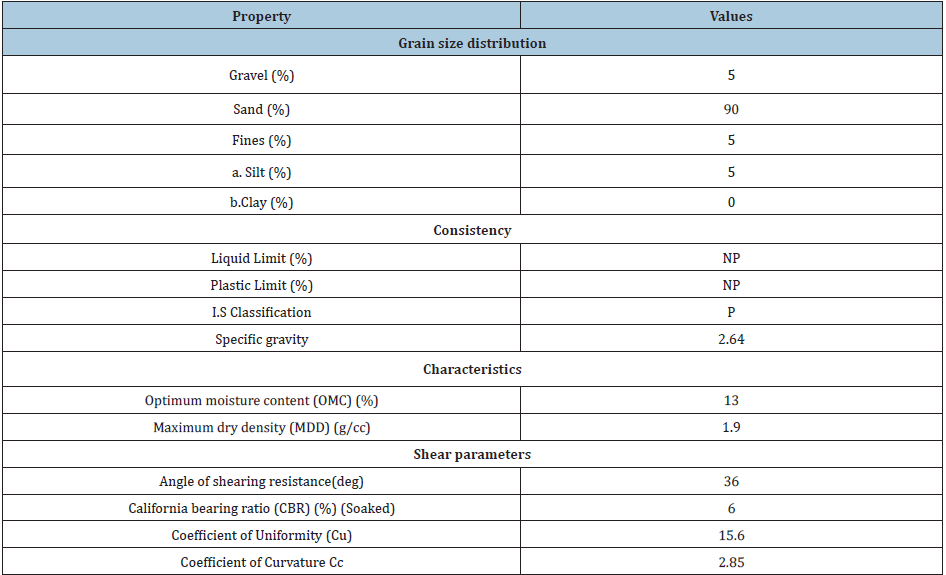

Table 1:

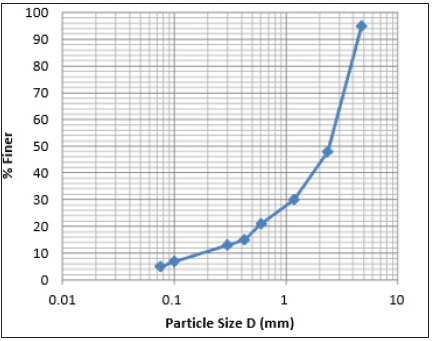

Figure 1:Gradation curve of crusher dust.

Figure 2:Compaction curve of crusher dust.

Methodology

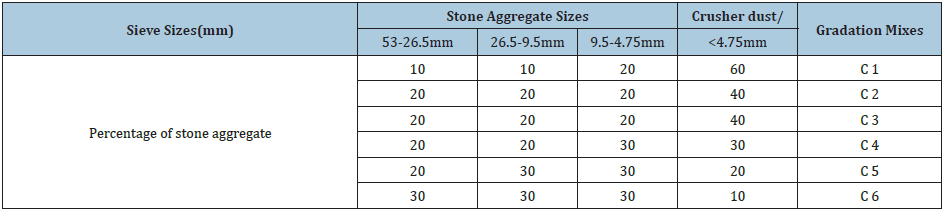

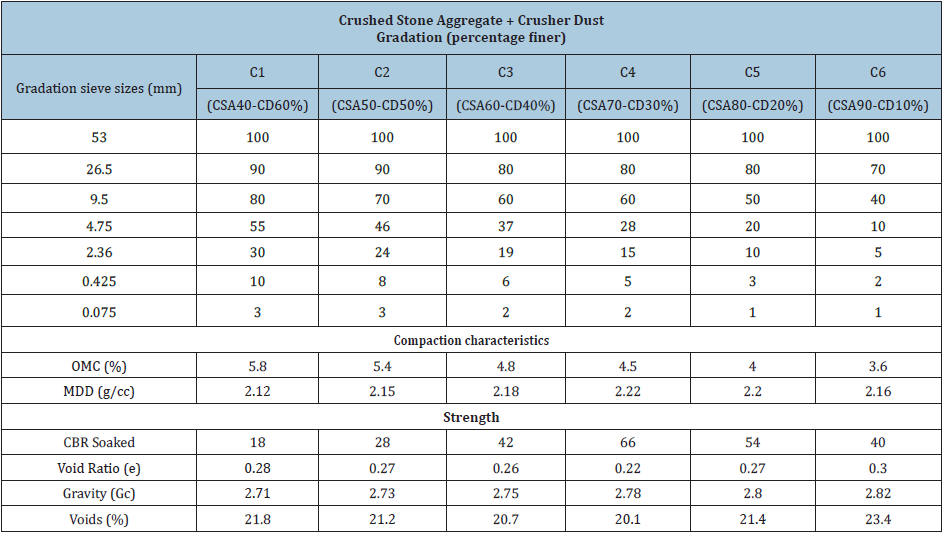

Crushed stone aggregate was obtained from nearby stone crusher plants of Cadet College Petaro (Field Picture). After brushing the aggregate, it was washed and dried. A set of sieves such as 53mm, 26.5mm, 9.5mm etc. have identified for the gradation of stone aggregate and for the fine aggregate 4.75mm, 2.36mm, 0.425mm, 0.075mm sizes were identified. Various percentages of stone aggregate were added to the Crusher Dust as listed below and also the percentage of Crusher Dust. Stone aggregate mixed with Crusher Dust was graded to various gradation mixes in accordance with NHA Pakistan specifications and named as C1, C2, C3, C4, C5, and C6 (Table 2).

Table 2:

Result and Discussion

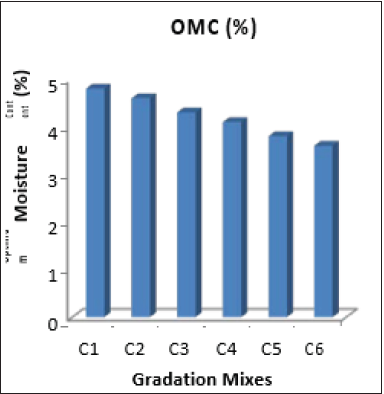

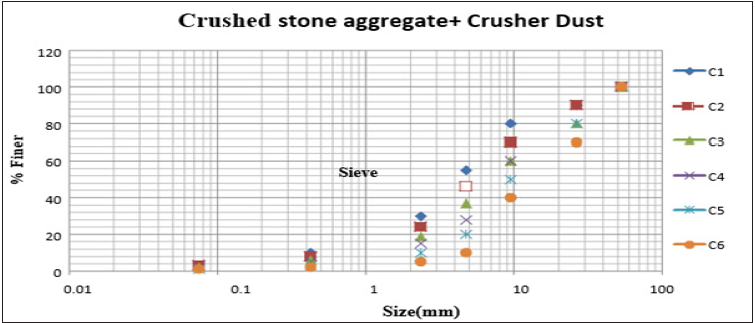

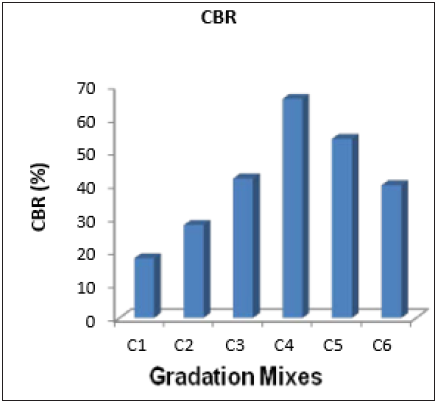

The gradations mixes were subjected to various geotechnical characterizations such as gradation, compaction, strength (CBR), void ratio etc. The results are listed below Table 3 and Figure 3-6.

Figure 3:

Figure 4:

Figure 5:

Figure 6:

Table 3:

Compaction characteristics

For the purpose of knowing the compaction characteristics of the designated gradation mixes C1, C2, C3, C4, C5 and C6 Modified proctor compaction test was performed as per standard Proctor test, ASTM D698 and AASHTO T 99 test methods and the results are shown in Table 3 and Figure 3 & 4. From the results of compaction test data, it is identified that maximum dry densities values are increasing with decrease in percentage of crusher dust with respect to Crushed Stone aggregate up to 25-20% and decreasing i.e. 2.12g/cc to 2.22g/cc and 2.22g/cc to 2.16g/cc respectively. Contemporarily it is also identified that OMC values are decreasing with decrease in percentage of crusher dust i.e., from 5.8 to 3.6%. Notable decrease in optimum moisture contents can be explained as at the higher percentages of crusher dust more water is needed to coat the crusher particles as it depends on composition, size and shape of crusher dust particles and at lower percentages less water is required due to less quantities of crusher dust particles available in the mixes. Attainment of lower and higher maximum dry densities can be explained in the following way. At higher percentages of crusher dust (50-60%) with respect to crushed stone aggregate more number of voids are opened up and all these not properly filled by crusher dust sediments forming honey combed structures with higher void ratios, at lower percentages of crusher dust(<20%) opening up of voids are taking place and crusher dust particles are not sufficient to fill up these voids resulting in development of honey combed structures. Effective replacement attained at 20-30% of crusher dust is due to filling up of formed voids partly with smaller size coarse aggregate and remaining by crusher dust particles responsible for attainment of higher densities. For a range of 20-30% of crusher dust addition, the gradation mixes became densely compacted with attainment of less void ratios and high densities.

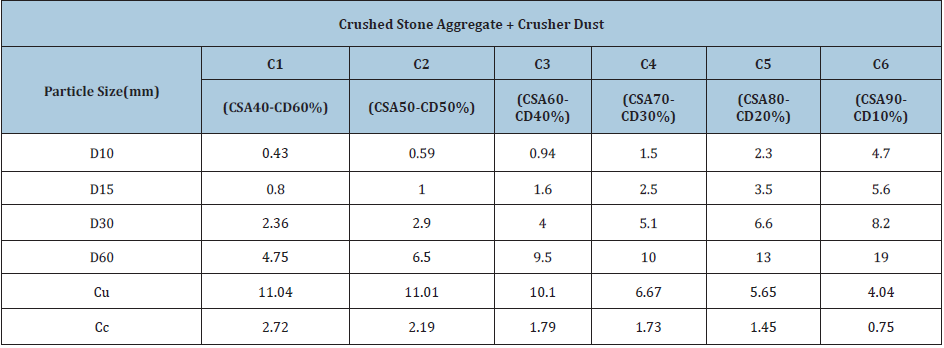

Particle size distribution curves

For the above gradation mixes C1, C2, C3, C4, C5 and C6 particle size distribution curves and their results were developed, and these are shown in Table 4 and Figure 5. From the test results it is observed that increase in the percentage of crusher dust decreases Cu and Cc values i.e. notable variation between Cu values from 11.04 to 4.04 and Cc values from 2.72 to 0.75 respectively. At higher percentage of crusher dust with respect to aggregate a wider variation in range of particles have been observed these may lead to higher values of Cu and Cc whereas at lower percentage of crusher dust lesser variation in range of particles have been observed and these may lead to lower values of Cu and Cc and make the mixes honey combing and less dense. Between the range of 20 and 30% of crusher dust the concerned gradation mixes try to maintain well graded conditions with dense packing in addition to shape and size of crusher dust particles may also be responsible for generation of these values.

Table 4:Grain size parameters.

California bearing ratio test

The collected Crushed Stone aggregate and crusher dust was dried and taken to the required proportions for the designated mixes C1 to C6 and compacted at their maximum dry densities in the CBR moulds and soaked for 4 days. After completion of the required soaking period the samples were tested in the CBR test apparatus at a strain rate of 1.25mm/min as per ASTM D1883- 05 Standard Test Method for CBR (California Bearing Ratio) of Laboratory-Compacted Soils From the test results of CBR the following identifications were made. According to results as the percentage of crusher dust decreases CBR values are increasing. It is clear that maximum values have been obtained at 30% dosage i.e. 66, a little decrease was observed from 30-20%. Let us consider the other parameters such as void ratio, percentage voids and maximum dry densities into account, it is found that a value of 20-30% crusher dust make the gradation mix ratio dense and offer more shear strength due to mobilization of friction resistance under compression.

Suitability of the gradation mixes a sub- base, base course materials

Comparing gradation mixes C1 to C6, with the gradation mixes of NHA Pakistan sub-base courses it is identified that at higher percentages of crusher dust these mixes are nearing to Grade- II and Grade- of close graded mixes and at lower percentages of crusher dust these are nearing to Grade-I. It can also be seen that the majority of the gradation mixes satisfying the Grades of coarse graded granular sub-base materials. Hence, the gradation mixes of crusher dust and Crusher stone aggregate with an addition of 20- 30% with respect to Crusher stone Aggregate attaining CBR value greater than 50 can be recommended as Base course and Sub-base course materials and the mixes having CBR greater than 30 can be used as Sub-base material.

Conclusion

As per the results the sizes of crusher dust sediments are mostly of medium to fine sand sizes uniform gradation of particles and of slightly lower specific gravities have closer packing with respect to crusher stone aggregates resulting higher densities and CBR values can be used as Sub-base base courses in flexible payment constructions.

References

- Ampadu SIK (2007) A laboratory investigation into the effect of water content on the CBR of a subgrade soil. Experimental unsaturated soil mechanics 112: 137-144.

- ASTM (2006) Standard test method for determination of water (moisture) content of soil by direct heating.

- Bahoria BV, Parbat DK, Naganaik, PB (2013) Replacement of natural sand in concrete by waste products: A state of art. Journal of Environmental Research and Development 7(4A): 1651.

- Delatte N (2018) Concrete pavement design, construction, and performance. CRC Press, USA.

- Donza H, Cabrera O, Irassar EF (2002) High-strength concrete with different fine aggregate. Cement and Concrete Research 32(11): 1755-1761.

- Gee GW, Or D (2002) 2.4 Particle-size analysis. Methods of soil analysis 4(598): 255-293.

- Ilangovana R, Mahendrana N, Nagamanib K (2008) Strength and durability properties of concrete containing quarry rock dust as fine aggregate. ARPN Journal of Engineering and Applied Sciences 3(5): 20-26.

- Kumar P, Chandra S, Vishal R (2006) Comparative study of different subbase materials. Journal of Materials in Civil Engineering 18(4): 576-580.

- Nagpal L, Dewangan A, Dhiman S, Kumar S (2013) Evaluation of strength characteristics of concrete using crushed stone dust as fine aggregate. International Journal of Innovative Technology and Exploring Engineering 2(6): 102-104.

- Nanda RP, Das AK, Moharana NC (2010) Stone crusher dust as a fine aggregate in concrete for paving blocks. International Journal of Civil and Structural Engineering 1(3): 613.

- Räisänen M (2004) From outcrops to dust: Mapping, testing, and quality assessment of aggregates.

- Sabat AK (2013) Prediction of California bearing ratio of a soil stabilized with lime and quarry dust using artificial neural network. Electronic Journal of Geotechnical Engineering 18: 3261-3272.

© 2020 Mushtaque Ahmed Pathan. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)