- Submissions

Full Text

Advancements in Civil Engineering & Technology

Mechanical-Thermo-Acoustic Analysis of Blocks of a Composite for Building Popular Houses

Meira DeSouza LG*, Gomes Dos Santos NR, Vieira Meira DeSouza LG and Pereira Neto RV

Department of Mechanical Engineering, Brazil

*Corresponding author:Meira DeSouza LG, Department of Mechanical Engineering, Brazil

Submission: December 11, 2019;Published: December 19, 2019

ISSN: 2639-0574 Volume3 Issue5

Abstract

It was presented the mechanical-thermo-acoustic characterization of a block-making composite for use in civil construction, with cement, marble and/or granite, plaster, EPS, sand, obtained in order to reduce the cost of building a residence, contributing to the reduction of the housing deficit and to removing harmful and immeasurable waste from the environment. The blocks made from the composite material obtained had as main characteristics the low cost, good compressive strength, low thermal conductivity, good acoustic resistance, good aesthetics, versatility, easy manufacturing and assembly processes and fast curing process. The work brings a combined study of the mechanical, thermal and acoustic resistances of the composite designed with the marble and marble/granite residues. It is emphasized that, besides the characterization of the conceived and produced composite, rooms were built, which demonstrated the mechanical viability of the proposed material and the thermal and acoustic resistance tests were performed in prototypes instead of the study restricted to the models. Blocks were manufactured with filling of 500 ml empty PETS bottles. Using the blocks with an area of around 0.2m2, four rooms were built with an area of 7.8m² each. The study determined which is the most viable block in relation to the combination of mechanical, thermal and acoustic resistances.

Introduction

The use of waste, especially those generated massively by industrial processes, represents a very important aspect in the study of composite materials. Composite materials are essential for changing the energy paradigms that can drive the transformations of collective thinking within the capitalist system, as they can produce new materials capable of significantly increasing the efficiency of renewable energy sources. In this context, it is understood that composite materials will play a fundamental role in the search for this paradigm break of thinking only in the most economically viable, for having a long-obtained technological domain. With the optimization and discovery of new materials it will be possible to evolve technologically and imagine a world less harmful to its population. Today it is impossible to imagine this reality in the short term, but only materials can lead to this technological transformation by the evolution of energy exchange efficiency in technological processes. In another aspect, natural and synthetic fibers have deserved prominence in obtaining new materials, with properties suitable for each purpose, such as fillers. Although industrial waste does not provide composites with structural reinforcement, the removal of the environment has a significant benefit to the sustainability of the earth. Removing from the environment what can bring harm is a very important contribution that researchers worldwide have made to minimize the harmful effects that such waste can cause.

Mining and beneficiation of ornamental rocks (marble, granite, quartz, slate and others) produce, at all stages of the process, (mining, beneficiation and finishing) a significant amount of solid waste, with an average material loss of 65 to 75% [1,2]. Besides representing losses in production, this significant amount of waste will affect the environment and productivity. In micro and small companies this waste is usually disposed of in the quarries themselves, causing great environmental and aesthetic impact. Brazilian exports of ornamental stones totaled US $144.69 million and 305,182.14 tons in the first two months of 2016. The average price of exported products fell by 13.68%, from US $549.2 / t in 2015 to US $474.1 / t in 2016. The most significant export increase was recorded for marble slabs [3].

The amount of waste that the ornamental stone industry produces is around 1,610,000 tons per year. The use of this waste for the production of building blocks is a way to reduce the negative environmental impacts caused by its inadequate disposal in the environment, and also to reduce the consumption of natural resources [4,5]. The tailings are discarded in settling ponds and landfills and are formed by materials of high fineness from the process of cutting, polishing and polishing pieces, made from marble and granite slabs [6,7]. The use of waste as fillers in civil construction has been widely sought as a way to lower the cost of building elements. Another strand in evidence is the combination of mechanical, thermal and acoustic properties, in obtaining constructive materials that promote thermal and acoustic comforts, as well as adequate mechanical resistance. Examples of this search are some recent studies developed and shown in the literature, shown below.

Yang W & Jun Moon H [8] investigated the influence of multisensory interaction in the acoustic, thermal, visual and internal environmental comforts with three internal environmental physical factors, acoustic, thermal and lighting conditions in an environmentally controlled laboratory. They concluded that the impact of acoustics on indoor environmental comfort was the highest among the three factors [8]. Echeverria CA et al. [9] studied the sound absorption in a series of 21 isotropic Hybrid Fiber Reinforced Composite (HFRC) prototypes, using the impedance tube method. The experimental results indicated low absorption coefficient at mid-frequencies (500Hz-2.5kHz) and a higher absorption (2.5-6.4kHz) coefficient at higher frequency ranges [9]. Ricciard P & Buratti C [10] investigated thermal, acoustical, and visual conditions in seven classrooms at the University of Pavia, Italy. Measurements of the main descriptors of thermal, acoustical, and visual comfort were carried out and new specific questionnaires were purposely developed, in order to investigate the students’ perception on acoustic and lighting comfort. The analysis of the lighting questionnaire showed that the average measured illuminance value has a high correlation with the perceived visual comfort [10].

Lemeurs D et al. [11] presented experimental and modelling study provides a general overview of the acoustical performance of hemp-lime and hemp-clay for building thermal insulation. They proposed a classification in terms of density to be used as a general guideline to evaluate or optimize the acoustical performances of hemp-based concrete [11]. Buratti C et al. [12] evaluated the thermal, acoustic and environmental performance of recycled waste panels consisting of rice husk (RH) produced by gluing and pressing the raw material. Thermal resistance of RH was equal to 0.59m2K/W, in the same order of magnitude of many traditional systems. Sound absorption coefficients were measured by means of the impedance tube. All the panels present acoustic absorption comparable with traditional ones (peak values 0.87-0.99). Karmann C et al. [13] demonstrated that there is little knowledge from occupied buildings of the impact of radiant heating and cooling systems on indoor environmental quality aspects such as thermal comfort, indoor air quality, and acoustics. They were present the survey results of 1645 occupants in buildings with radiant systems. They concluded that radiant and all-air spaces have equal indoor environmental quality with a tendency towards improved temperature satisfaction in radiant buildings [13]. Pedroso M et al. [14] presented results for materials used currently and alternative materials available in the construction market to control noise in buildings. The characterization at the level of embodied energy, acoustic behavior and costs of these materials was presented. They concluded that there are alternative materials that, from the acoustic behavior, embodied energy and costs points of view, are perfectly viable to replace the currently used products [14].

Kang J et al. [15] pointed out that Soundscape research represents a paradigm shift from noise control policies towards a new multidisciplinary approach as it involves not only physical measurements but also the cooperation of humanity and social sciences to account for the diversity of soundscapes across countries and cultures. The ten questions presented range from the very basic definitions underlying the emerging soundscape science. The last question aimed to identify the most crucial gaps in soundscape research and set the agenda for future advancements in the field. Morales L et al. [16] described the acoustic aspects of the main cathedrals of Andalusia. The monumental size of these buildings and the characteristics of the materials used in their construction render cathedrals highly reverberant spaces. They concluded that both the distribution of the early reflected energy, and the acoustic characteristic of reverberation, spaciousness, strength, and clarity set for favorable transmission of spoken or sung messages and music, exhibit a remarkable dependence on sound-source location and its areas of influence.

Reixach R et al. [17] investigated the acoustic properties of natural fiber reinforced composites. Fibers from orange tree pruning were obtained and subject to different treatments in order to obtain mechanical, thermomechanical and chemithermomechanical pulps. These pulps were used as reinforcement for a polypropylene matrix. The obtained composite materials were submitted to acoustical tests in an impedance tubes device. They compared their results with those obtained using other methods most usual lightweight soundproof solutions. This work presents the mechanical-thermo-acoustic characterization of a composite made of cement, marble and / or granite residue, plaster, EPS, sand, obtained in order to reduce the cost of building a residence and, thus, contribute with existing efforts to reduce the housing deficit and contribute to the removal of harmful and immeasurable waste from the environment [18,19]. The blocks made of the composite obtained had the main characteristics: low cost, good compressive strength, low thermal conductivity, good acoustic resistance, good aesthetics, versatility and easy manufacturing and assembly processes. Another great advantage of the composite produced was its fast curing process allowing considerable agility of the construction process. Also noteworthy is the good finish of the block produced, thus reducing the cost of labor due to the lack of finishing. The composite obtained can also be used for the construction of homes through the on-site launching technique.

The work brings a combined study of the mechanical, thermal and acoustic resistances of the composite designed with the marble and marble/granite residues. The works found in the literature of composite materials aimed at the manufacture of blocks generally only bring mechanical characterization. It is emphasized that, besides the characterization of the conceived and produced composite, rooms were built, which demonstrated the mechanical viability of the proposed material and the thermal and acoustic resistance tests were performed in prototypes instead of the study restricted to the models. Relevant literature presents. Blocks were filled with filling of 500ml empty PETS bottles. With the blocks with an area of around 0.2m², four rooms were built that constituted a house, with an area of 7.8m² each. The study determined which is the most viable block in relation to the combination of mechanical, thermal and acoustic resistances. Preliminary tests were performed to determine the most suitable composite formulation. To reach the construction phase of the blocks, the following steps were taken: waste collection, transportation to the place of manufacture of the blocks, preparation of the molds, cleaning of the mold parts. Then each constituent material was separated, and then each element was mixed to prepare the composite, which was poured into the mold.

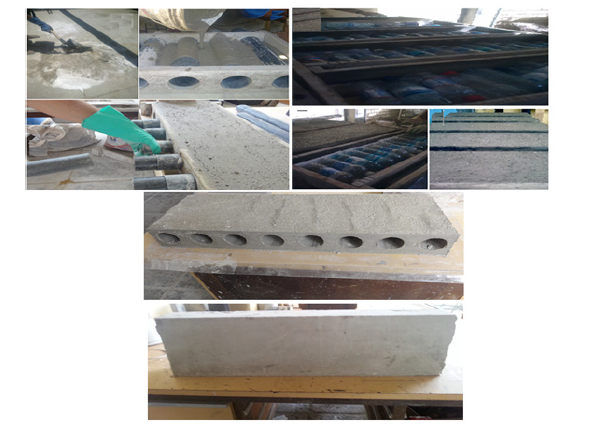

The proposed composite was obtained using variations of cement proportions, marble residue powder / granite residue powder, plaster, EPS and sand. Water was added at approximately 50% of the dry volume for the mixing and homogenization of the composite. The amount of each mixed constituent was measured by volume for ease of operation. Type CP II cement containing 35 to 70% blast furnace slag and quick plaster was used. Styrofoam pieces collected from appliance stores were used. The marble and granite residues were collected in marbles, mixed with water to form a pulp. They were generated after the pieces of granite and marble were polished and cut in aqueous medium, moving a dense mud that after drying was called marble/granite powder mud. Once manufactured, the blocks were transported to the building site. Figure 1 shows some of the steps of the manufacturing process of blocks types 1 and 2, with the dimensions: 0.80m x 0.28m x 0.10m [18,19].

Figure 1:Stages of the manufacturing process for Type 1 void blocks and Pets 2 type bottle fillers.

Among the formulations that used the tested residues, RM / RMG, the one with the highest resistance was 1C + 1G + 1RM + 2A with a favorable value for both masonries, sealing and structural, above 3.5MPa. The formulations with the introduction of industrial residues presented mechanical strength also compatible with the requirements of the relevant standard for both types of masonry, between 3.5 and 4.5MPa. As one of the objectives of the work was the search for a material that would allow the manufacture of blocks with adequate mechanical and thermal resistances, the formulation 1C + 1 G +1 ISO + 1RM + 2A was chosen for the composite production and subsequent fabrication of the blocks. blocks for future building of the rooms. Four rooms were built: room 1-type 1 blocks and residues of crushed marble and styrofoam; room 2-eight hole bricks; room 3-type 2 blocks with marble/ granite dust and crushed styro-foam residues; room 4-blocks type 1 and crushed marble/granite and styro-foam dust residues. Figure 2 shows the four rooms built. All rooms had an internal area of 7.8m2 (3.00m x 2.60m) and the height of the walls ranged from 2.20 m west side and 2.40m east side. Due to the ease of transport and lower cost, asbestos-free fiber-cement roof tiles were chosen as cover.

Figure 2:The four rooms under construction and after construction.

Thermal tests

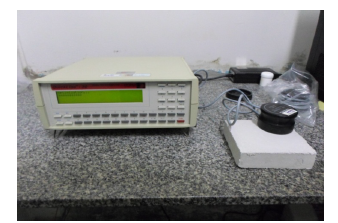

One of the aspects of the work concerns the possibility of verifying the thermal resistance behavior of the built block. To confirm this possibility, thermal tests were performed to determine the thermal conductivity, thermal diffusivity and heat capacity of the composite produced [18]. Thermal parameters were measured using Quick-line 30 (Anter Thermal Properties Corp.) equipment which measures thermal properties based on the analysis of the material’s thermal response to excitation through a thermal flow. Figure 3 shows the equipment, the sensor and one of the samples used in the composite thermal test.

Figure 3:Quick-line 30 equipment used in composite thermal testing.

Thermal comfort test

Measurements were made with open and closed doors and windows. There was no movement of people beyond the meters themselves and no appliances capable of producing heat inside. Data collection was performed on days with good solarimetric conditions [18,20-25]. Type K thermocouples were fixed in the central region of the housing unit 1.5 meters above the floor. The cromel-alumel thermocouples were connected to a digital thermometer to measure the temperature of the indoor environment. Data acquisition on the walls was performed manually by means of a manual reading infrared thermometer positioned on the wall at a distance of 0.1m. Temperatures were measured from 08:00 to 14:00. The temperatures of the inside and outside surfaces of the tile were measured with an infrared thermometer also every thirty minutes. They were measured at three points on both surfaces. A thermal stress meter recorded the following meteorological parameters, between eight and fourteen hours, every half hour: indoor air temperature, wind speed, wet and dry bulb temperatures. relative air. Global solar radiation was measured with an Instrutherm radiometer every five minutes.

Acoustic test

The instrument used to generate the beep was a function generator. To transmit the sound, four speakers and Leadership sub-wolf speakers were coupled to the equipment to direct the sound to the wall. The instrument used for sound pressure measurements was a LT Lutron decibel meter, model SL-4012 [18,23,26-28]. The equipment had the ability to measure the equivalent sound pressure level (Leq) as per IEC 60804, and parallel measurements of Lp, Lpk (time weighted): Start / Stop, 30- 140db in a single range. It had real-time octave (1/1) band filter (16Hz-16Hz)-average, minimum, maximum and real-time octave (1/3) band filter (12.5Hz-20Hz)-average, minimum, maximum. The sound pressure levels of the measurement points were determined according to the weighting of the C scale, expressed in dB, according to the adopted technical standard. Meter slow response indication was used. Sound was emitted from the inner wall, and attenuation or enlargement was measured at the outer wall. Measurements for acoustic performance evaluation occurred in the period from 8:00 to 16:00. The decibel meter was located 0.50m from the floor, leaning against the wall in all rooms. Figure 4 shows the equipment used in the acoustic test.

Figure 4:Acoustic test of composite blocks. a) equipment directing the measurement point, b) measurement performance c) Equipment used in the acoustic test.

Results and Discussion

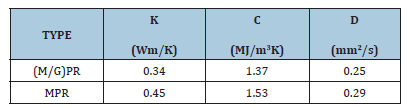

The average thermal conductivity of the marble powder composite has increased by 32.3% over marble/granite, the thermal diffusivity by 11.6% and the volumetric thermal capacity by 16% (Table 1). For the volumetric thermal capacity and diffusivity, the marble/granite residues presented better results. Regarding the comparison between the most commonly used building materials, 8-hole bricks and concrete blocks, the thermal conductivity of the composite in the chosen formulation was much lower, being 62% lower for marble/granite waste and 80% lower than concrete blocks, which demonstrated the feasibility of producing a higher thermal comfort of the composite blocks, as they provide a higher thermal resistance. The thermal conductivity of the composites with marble dust and marble dust/granite residues through the averages of values found came very close to the expressed conductivity of the gypsum plates and inferior to the bricks, proving that they behaved as materials with greater insulation.

Table 1:Presents the average thermal test results for marble/granite and marble residue composites.

After proving that the composite material produced had a much lower thermal conductivity than the conventional construction materials, concrete block and eight-hole brick, it was started to perform tests aiming to prove that the blocks would provide greater thermal comfort in their design. inside. For this diagnosis, the external and internal temperatures of the walls and the temperature of the internal environment of each room were measured. For a comparative analysis it was essential that all rooms were subject to the same environmental and solarimetric conditions. It was intended to demonstrate that the rooms built with blocks made of composite material provided greater thermal comfort. However, it was noticed that the temperatures of the outer surfaces of the room built with conventional eight-hole bricks were always higher than those of alternative rooms. This was due to a higher absorption of solar radiation as a function of the color and material of the wall, which was towed.

However, it was noticed that the temperatures of the internal walls of the conventional room were always higher than those of the room walls with alternative blocks, but due to the greater absorption of the plastered wall, the comparative analysis was compromised. However, the comparative analysis between the alternative rooms can be done, and since the conductivity of the composite material was much lower, it was understood that the thermal comfort provided by the blocks that built the rooms was higher. Another fundamental parameter for the comfort analysis would be the thermal sensation inside the rooms. As we had no equipment to determine this parameter, a thermal sensation test was performed by calculating the effective temperature. Another alternative check was to enter the rooms and spend a few minutes under your comfortable conditions. Then one went to another and the procedure was repeated. Thus, it was perceived and determined which room was most comfortable. It is noteworthy that the conditions for thermal comfort are various and that this theme would be the object of further study. It would require a data acquisition system capable of holding and storing multiple points at the same time for a real analysis of the comparative behavior between the conventional and alternative materials used.

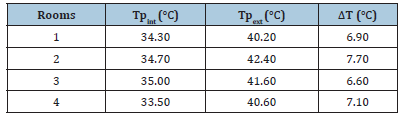

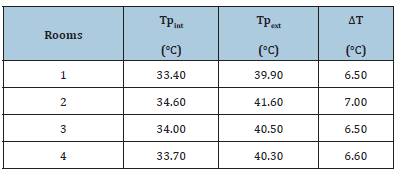

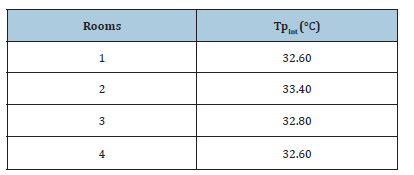

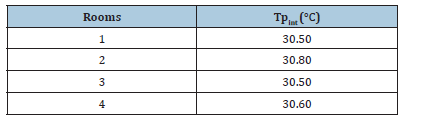

However, it is understood that the results obtained constitute a preliminary indication to diagnose thermal comfort conditions associated with the thermal resistance provided by the blocks used in the construction of the rooms. Table 2 & 3 present the results of the parameters measured during the east and west wall tests, for the diagnosis of thermal comfort. The two adopted configurations were analyzed: open and closed door and window, in the east and west walls. For a better comparison between the rooms in the two configurations tested, the average external and internal temperatures are presented in Table 4 & 5.

Table 2:Average temperatures of the walls of the roomsopen configuration.

Table 3:Average temperatures of the walls of the rooms-configuration closed.

Table 4:Interior temperature of each room-closed setting.

Table 5:Interior temperature of each room-open configuration.

The average internal and external temperatures of the two walls of the rooms exposed to radiation for the configuration with open doors and windows showed that the alternative rooms with voids, with temperature variation of 7.10 ºC, presented higher thermal resistance, which allowed us to assume that it would provide greater thermal comfort. In relation to the inner walls, this room was the one that presented the lowest temperature and in relation to the outside temperature, the room with the conventional bricks presented the highest temperature due to the absorptivity of its walls, which induced a larger temperature difference. between the outer and inner surfaces. Table 3 presents the average temperature values on both sides of the walls for the closed configuration.

All rooms built with composite material blocks had the same behavior with respect to thermal resistance and could therefore also provide thermal comfort. It was noticed that the temperatures of the west, inner and outer walls were always higher than those of the east walls, as the percentage of solar illumination on the east walls was decreasing throughout the morning, which was not the case with the west walls in that from noon onwards there was always an increase in the sunny area. Other factors that may have influenced this higher west wall temperature were the lower incidence of wind and the heat buildup caused by heating the other sunny walls in the morning. Regarding the ambient temperature inside each room, the average results obtained are shown in Table 4. It was observed that the average internal temperature of each room built with the blocks of composite material, for voids and filling in the configuration with closed doors and windows, was practically the same. The room built with conventional eight-hole bricks had a higher internal temperature of 2.5%. From the data in Table 5 it was noticed that all the rooms presented similar behavior and it could not be said that the rooms built with the blocks offered higher thermal resistance than the conventionally built room, for the reasons already highlighted.

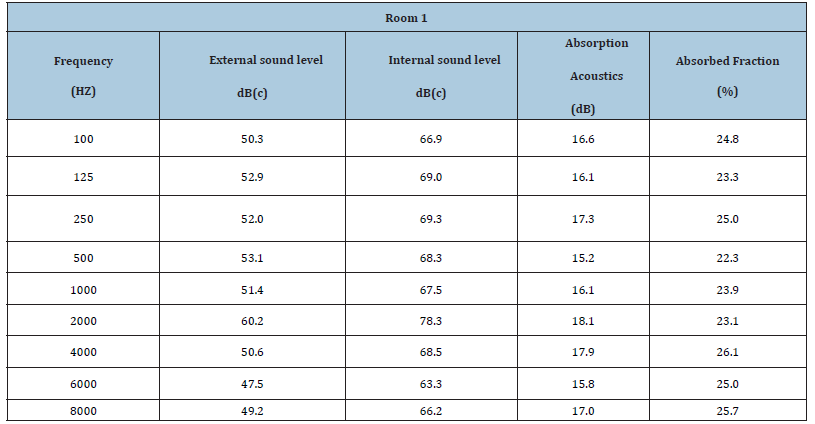

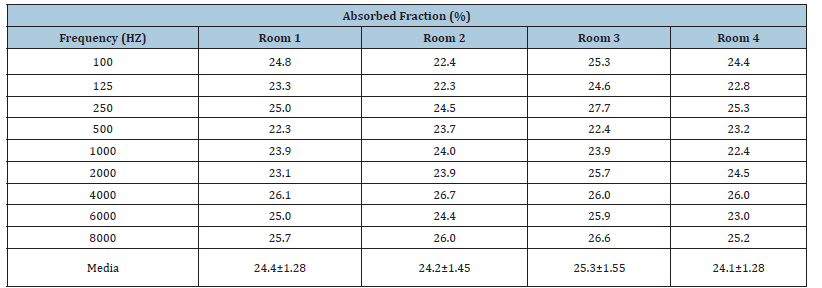

For this configuration, similar behavior was observed once again in relation to the average internal temperature of each room, with no thermal resistance supremacy of the blocks made of composite material in relation to the conventional eight-hole brick. Despite this similarity it was noticed that the most comfortable thermal sensation was provided by the blocks filled with PET bottles, which represented an ecologically positive factor, since the use of numerous Pets bottles caused the removal of materials harmful to the environment. It is also noteworthy that the blocks produced had the advantage of not requiring plastering, which reduced the labor cost of the building. In addition, the time to build the building was also shorter due to the larger area of the blocks. It is noteworthy that for a new construction the length of the blocks should be reduced to allow even more agility of the construction process. The average results of the acoustic parameter measurements performed in each room are presented. A comparative analysis of these parameters was performed between the rooms built with the blocks of composite material manufactured and the conventional bricks used for the construction of the walls of room 2. Table 6 presents the average acoustic parameters for room 1.

Table 6:Average acoustic parameters for Room 1.

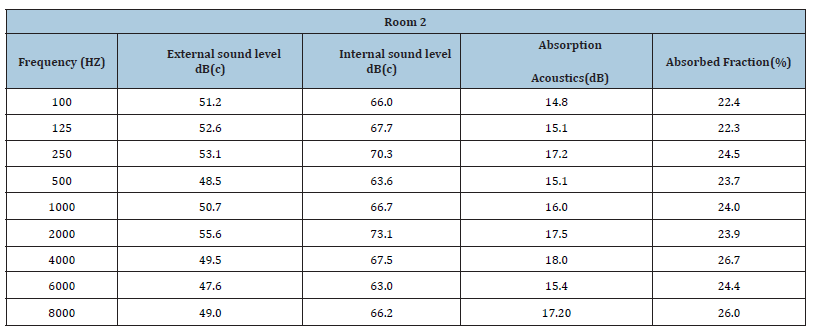

It was noticed that for this room built with hollow blocks of composite material that used marble residue dust the highest acoustic absorption occurred at the frequency of 4000Hz, corresponding to 26.1% and the lowest was at the frequency of 500Hz. Acoustic absorption averaging for all frequencies yielded 24.4%. Table 7 presents the average acoustic parameters for Room 2, built by conventional bricks. For this room, built with conventional eight-hole bricks, we obtained an average acoustic absorption like that of room 1, reaching a maximum absorption of 26.7% for 4000Hz. The average absorption of all frequencies corresponded to 24.2%. Table 8 presents the average acoustic parameters for Room 3, made up of blocks of composite material filled with Pets bottles.

Table 7:Average acoustic parameters for Room 2.

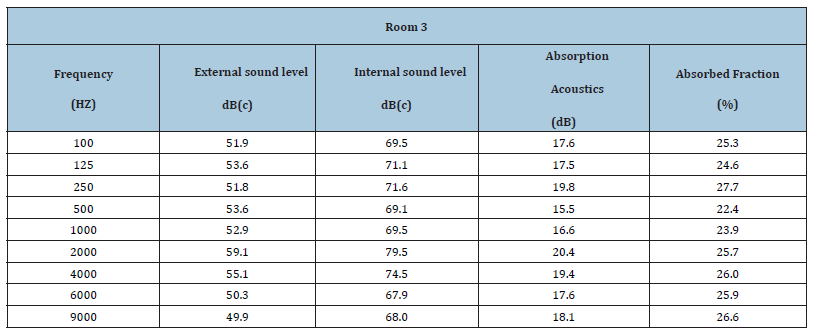

Table 8:Sound level as a function of frequency Room 3.

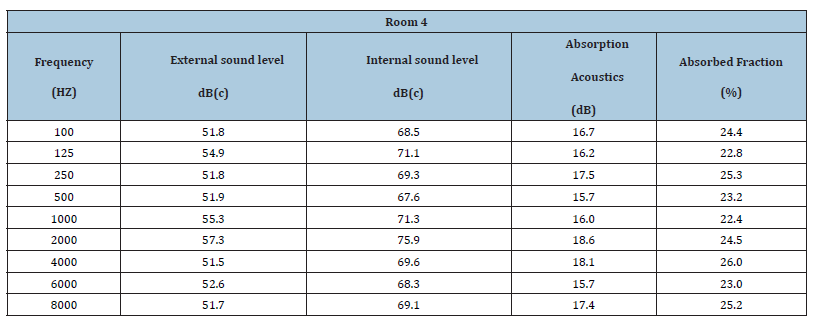

Table 9:Sound level as a function of frequency Room 4.

Table 10:Sound level as a function of frequency Room 4.

For this room there was a slight increase in the level of sound absorption compared to the room built with conventional eighthole bricks. The average absorption of all frequencies was around 25.3%. There was a higher absorption capacity for high frequencies. Table 9 presents the average acoustic parameters for Room 4, built with type 1 blocks and marble/granite residues. The absorption capacity of the walls of this room behaved similarly to the one built with conventional and plastered bricks, with an average value for all frequencies of around 24.1%. The behavior of the anterior room was repeated for greater absorption capacity at high frequencies. Table 10 presents the average sound absorption levels for all rooms.

Conclusions and Suggestions

Based on the results of the mechanical, thermal and acoustic tests performed with the composite under study, the following conclusions and suggestions are presented.

Conclusion

A. It was feasible to obtain a composite for use as a building

material from marble and granite waste powders and crushed EPS.

B. The use of crushed EPS residue caused mechanical

damage to the composite but increased the thermal resistance of

the block made with it.

C. The best combination ratio between mechanical and

thermal resistances was the one that used 1C + 1G + 2A + 1EPS

+ 1RM / G and was therefore chosen for the manufacture of the

blocks.

D. The thermal conductivity of the composite (0.34-045W/

mK) was much lower than that of traditional concrete (07-

09W/mK) and eight-hole brick between 06 and 07W/mK, This

demonstrated the feasibility of producing a higher thermal comfort

of the composite blocks, as they provide a higher thermal resistance.

E. The thermal diffusivity of the composite was lower than

relative to conventional masonry because of its higher thermal

resistance capacity.

F. All rooms made of composite material blocks had identical

heat resistance behavior and could therefore provide thermal

comfort as well.

G. The most comfortable thermal sensation was provided

by the Type 2 blocks, which represented an ecologically positive

factor, since the use of numerous Pets bottles led to the removal of

environmentally harmful materials.

H. Pet bottle-filled blocks had greater acoustic absorption

capacity for all tested frequencies, with a supremacy of around

5.0% over conventional brick and up to 5.2% over blocks made of

voids.

I. Regarding the frequency level there was a similar behavior

for all rooms with higher absorption for the high frequency range

above 1000Hz.

J. The highest level of sound absorption was for room 3

(marble dust composite + hollow block) at 250Hz.

K. For all tested building elements there was a higher

absorption capacity for the higher frequency ranges.

L. Both types of blocks used had similar sound absorption

capacity, superior to type 2 block.

M. For the high frequency bands there was a greater acoustic

absorption capacity for all blocks, with supremacy for those made

of PETS bottle-filled composite material.

N. The most viable block type combining thermal and

acoustic resistances was type 2, with Pets bottle fillings.

Suggestions

a. Make the blocks filled with more efficient materials for

sound absorption or include a new material to be added to cement,

sand and plaster, such as cork grains.

b. Test the acoustic absorption capacity of other residues

already studied, wood dust, eggshell dust, acai fibers, vegetable

bushing, corncob dust, among others.

c. Fabricate blocks with other geometries and test their

mechanical-thermo-acoustic capabilities.

References

- FIEMG (2015) Environmental technical guide for the ornamental stone industry/State Environmental Foundation, Federation of Industries of the State of Minas Gerais. FEAM, Belo Horizonte, Brazil.

- Costa LCF (2017) Obtaining and studying a polyester matrix composite and marble waste filler, Master's dissertation PPGEM/UFRN, Brazil.

- Galetakis M, Soultana A (2016) A review on the utilization of quarry and ornamental stone industry fine by-products in the construction sector. Constr Build Mater 102(1): 769-781.

- Bastos RS (2013) Concrete produced with waste from the processing of ornamental stones as a partial cement substitute. 55th CBC2013, Joinville, Brazil.

- Corinaldesi V, Moriconi G (2010) Recycling of rubble from building demolition for low-shrinkage concretes. Waste management 30(4): 655-659.

- Matta VRP (2012) Influence of the addition of marble and granite cutting residue on the properties of hardened Portland cement mortars. 20th

- Yang W, Jun Moon H (2019) Combined effects of acoustic, thermal and lighting conditions of comfort of discrete senses and overall indoor environment. Building and Environment.

- Echeverria CA, Pahlevani F, Handoko W, Jiang C, Con Doolan et al. (2019) Engineered hybrid fiber reinforced composites for sound absorption building applications. Resources, Conservation and Recycling 143(1): 1-14.

- Ricciard P, Buratti C (2018) Environmental quality of university classrooms: Subjective and objective evaluation of thermal, acoustic, and lighting comfort conditions. Building and Environment 127: 23-36.

- Degrave Lemeurs M, Gle P, Menibus AH (2018) Acoustical properties of hemp concretes for buildings thermal insulation: Application to clay and lime binders. Construction and Building Materials 160: 462-474.

- Buratti C, Belloni E, Lascaro E, Merli F, Ricciardi P (2018) Rice husk panels for building applications: Thermal, acoustic and environmental characterization and comparison with other innovative recycled waste material. Construction and Building Materials 171: 338-349.

- Karmann C, Schiavon S, Graham LT, Raftery P, Bauman F (2017) Comparing temperature and acoustic satisfaction in 60 radiant and all-air buildings. Building and Environment 126: 431-441.

- Pedroso M, Brito J, Silvestre JD (2017) Characterization of eco-efficient acoustic insulation materials (traditional and innovative). Construction and Building Materials 140: 221-228.

- Kang J, Aletta F, Gjestland TT, Brown LA, Bottledooren D, et al. (2016) Ten questions on the soundscapes of the built environment. Building and Environment 108: 284-294.

- Morales L, Giron S, Galindo M, Zamarreno T (2016) Acoustic Environment of Andalusian Cathedrals. Building and Environment 103: 182-192.

- Reixach R, Del Rey R, Alba J, Arbat G, Espinach FX, et al. (2015) Acoustic properties of agroforestry waste orange pruning fibers reinforced polypropylene composites as an alternative to laminated gypsum boards. Construction and Building Materials 77: 124-129.

- Dos Santos NRG (2015) Mechanical, thermal and acoustic characterization of a composite that uses marble, granite and EPS tailings for the manufacture of building blocks. Doctoral Thesis PPGEM-UFRN, Brazil.

- Costa LCF (2017) Obtaining and study of a polyester matrix composite and marble waste load. Master's Dissertation-PPGEM-UFRN, Brazil.

- Souza LGVM (2018) Hybridization effect of a polyester resin matrix composite and cotton fiber fabric filler with an E type fiberglass fabric filler. PhD Thesis PPGEM-UFRN, Brazil.

- Technical Standards, NBR 10151, NBR 10152, NBR 6136, NBR 13818, NBR 15220-1, NBR 15220-2, NBR 15270-1, NBR 6502.

- Araujo BCD (2010) Proposal of acoustic cast element. Thesis, University of Sao Paulo, Brazil.

- Adamczyk J, Dylewski R (2011) Economic and environmental benefits of thermal insulation of building external walls. Building and Environment 46(12): 2615-2623.

- Carfan AC (2011) Analysis of thermal comfort in open areas in the municipality of Ourinhos-SP. Thesis, University of São Paulo, Brazil.

- Correia CMP (2009) Thermo-acoustic comfort of a low-cost housing. Thesis. University of Sao Paulo, Brazil.

- Lima FAS (2016) Obtaining and characterizing a ceramic matrix composite with EPS waste loads and tire scrapes for building popular homes. Thesis. Federal University of Rio Grande do Norte, Brazil.

- Moreno ACR (2013) My house my life: Thermal performance analysis by NBR15.220-3, NBR 15.575, blue house seal and RTQ-R. Dissertation. Federal University of Minas Gerais, Brazil.

- Michalski RLXN (2011) Methodologies for measuring sound insulation in the field and for expressing measurement uncertainty in assessing acoustic performance of buildings. Thesis. Coppe Federal University of Rio de Janeiro, Brazil.

- Aguiar BFR (2012) Study of the sound insulation of a panel based on the cupuaçu bark. Federal University of Pará, Brazil.

© 2019 Meira DeSouza LG. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)