- Submissions

Full Text

Advancements in Civil Engineering & Technology

Scanning Electron Microscope Configuration of Recycled Carbon Fiber Composites: Mini Review

Seyed Hossein Mamanpush1*, Azadeh Tavousi Tabatabaei1,2 and Bahareh Tavousi Tabatabaei3

1 Composite Materials and Engineering Center, USA

2 Department of chemistry, Iran

33Department of Engineering, Iran

*Corresponding author: Seyed Hossein Mamanpush, Composite Materials and Engineering Center, USA

Submission: October 25, 2018;Published: November 06, 2018

Volume2 Issue4November 2018

Abstract

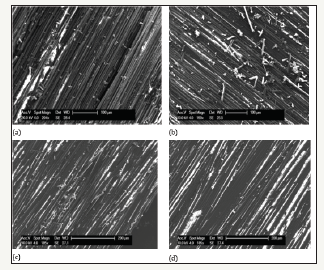

Carbon fiber composites (CFCs) were mechanically refined and classified the scanning electron microscope (SEM) configuration of untreated and heat-treated mechanically recycled carbon fiber epoxy and carbon fiber vinyl ester composite was examined by using scanning electron microscopy (SEM). SEM Results indicate that the main defects in the structure of recycled CFCs are broken fibers, fiber pull-out, fiber-matrix separation. Also Comparing SEM of untreated and heat-treated recycled CFC indicates that there is no significant difference between their micrographs.

Keywords: Carbon fiber composites; Recycling; Scanning electron microscope

SEM Observation

The CFC trimmings and off-cuts were mechanically refined through two methods: hammer milling with a 25.4mm screen and shredding with 19mm wide teeth. The hammer-milled material was then sieved to different fractions as retained in 19.05mm (19.05), passed to 19.05mm and retained 12.7mm (12.7) passed 12.7mm and retained 4.7mm (4.7), and passed 4.7mm (< 4.7), respectively. The materials processed by the shredder were screened with a 12.7mm screen and utilized as-is for the recycled composite process [1]. The SEM configurations of untreated and heat-treated recycled carbon fiber composites (rCFCs) are given in Figure 1. rCFCs were heat-treated at 360 °C for 10min [2-4] based on the thermal properties of rCFCs. [5-8]. SEM configuration of CFCs shows different kinds of defects in the structure of composites including broken fibers, fiber pull-out, fiber-matrix separation. These defects maybe caused reaching of CFC to the end of life or can be created during recycling process [9-10]. Comparing SEM of untreated and heat treated rCFC indicates that there is no significant difference between their micrographs.

Figure 1:SEM configurations of rCFC under different conditions: (a) untreated Epoxy/CFC (b) heat-treated Epoxy/CFC (c) untreated VE/CFC (d) heat-treated VE/CFC.

References

- Hui Li, Karl Englund (2016) Recycling of carbon fiber-reinforced thermoplastic composite wastes from the aerospace industry. Journal of Composite Materials 51(9): 1265-1273.

- Mamanpush H, Golestanian H (2014) Investigating the effects of carbon nanotube orientation on the macroscopic stiffness of nanocomposites. Int J Curr Life Sci 4(4): 1168-1174.

- Mamanpush H, Golestanian H (2014) Evaluation of effective material properties of randomly distributed carbon nanotube composites considering interface effect. Indian J Sci Res 2(1):132-142.

- Thostenson ET, Karandikar PG, Chou TW (2005) Fabrication a characterization of reaction bonded silicon carbide/carbon nanotube composites. J Phys D Appl Phys 38(21): 3962-3965.

- Song YS, Youn JR (2006) Modeling of effective elastic properties fo polymer- based carbon nanotube composites. Polymer 47(5): 1741-1748.

- Mamanpush H, Golestanian H (2014) Effects of carbon nanotube dispersion on the mechanical properties of nanocomposites considering interface effect. International Journal of Current Research 4(8): 4366- 4373.

- Seyed Hossein Mamanpush, Hui Li, Karl Englund, Azadeh Tavousi Tabatabaei (2018) Recycled wind turbine blades as a feedstock for second generation composites. Waste Management 76: 708-714.

- Seyed Hossein Mamanpush, Azadeh Tavousi Tabatabaei, Hui Li, Karl Englund (2018) Data on the mechanical properties of recycled wind turbine blade composites. Data in Brief 19: 230-235.

- Seyed Hossein Mamanpush, Hui Li, Karl Englund, Azadeh Tavousi Tabatabaei (2018) Dataset demonstrating physical properties of recycled wind turbine blade composites. Data in Brief 20: 658-661.

- Seyed HM, Azadeh TT (2018) Innovative method in recycling wind turbine blades: mini review. Evolutions Mech Eng 1(1). 1-2.

© 2018 Seyed Hossein Mamanpush. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)