- Submissions

Full Text

Advancements in Civil Engineering & Technology

Towards A Real-Time Data-Driven Approach for Proactive Injury Prevention in Construction

Esther Obonyo1* and Junqi Zhao2

1 Engineering Design and Architectural Engineering, The Pennsylvania State University, USA

2 Architectural Engineering, The Pennsylvania State University, USA

*Corresponding author: Esther Obonyo, Associate Professor, Engineering Design and Architectural Engineering, The Pennsylvania State University, University Park, PA, USA

Submission: August 17, 2018;Published: August 30, 2018

Volume2 Issue2August 2018

Abstract

There is a need for more proactive injury prevention strategies that can enhance the progress towards zero injuries and fatalities in construction. There is a specific focus on Musculoskeletal Disorders (MSD), which according to the National Institute for Occupational Safety and Health (NIOSH)’s definition is a “soft-tissue injuries caused by sudden or sustained exposure to repetitive motion, force, vibration, and awkward positions” that “affect the muscles, nerves, tendons, joints, and cartilage in the upper and lower limbs, neck and lower back. “There are some knowledge gaps impeding the design and development of intervention strategies. This paper presents preliminary findings from research directed at investigating the potential for addressing this need through leveraging emerging sensor-based technologies using real-time data. The proposed approach leverages emerging lowcost wearable sensing and advanced data analytics techniques. One of the key barriers to injury prevention is the lack of reliable data on the complex interactions across contributing factors.

Lessons can be learned from a “Web of Causation” approach that is being used to characterize and analyse the development progress of the disease. This is a data-intensive approach. It is the contention of this paper that the required data collection and processing needs can be addressed using emerging Wearable Technologies (WT). The collected motion data can be used to improve the detection of activities that have MSD-related risks and enhance the understanding of the nature of the risk. The output can be used to perform more robust quantitative assessments of risk factors. It can also be used to develop proactive strategies that can be used to minimize the occurrence of MSD.

Keywords: Construction safety; Injury prevention; Data analytics; Musculoskeletal disorders

Introduction

In 2014, Workers’ compensation programs paid an estimated $62.3 billion in benefits across all sectors (Workers’ Compensation 2016). In the U.S., the construction industry employs approximately 4.0% of the total labor force but accounted for an estimated 18.6% of all fatal and 5.6% of the non-fatal injuries in 2014(U.S. Bureau of Labour Statistics 2016). In 2010 alone, construction workers received nearly three times the average compensation cost for employees in all industry (CPWR 2013). Clearly, this sector has a disproportionately large share of work-related injuries and illnesses. Although significant effort has been invested in promoting safe practices on the job site [1-4], the goal of “zero injuries and fatalities” is still far from being realized. Specific examples of work have been accomplished so far include safety training programs championed by OSHA (Occupational Safety and Health Administration - see [2]; the Electronic Library of Construction Safety and Health (eLCOSH) that is managed by the U.S. National Institute for Occupational Safety and Health (NIOSH) see [3]; and also Construction Industry Institute (CII)’s Safety Knowledge Base [1]. These programs are reactive in nature.

There is an underexploited opportunity to save costs through preventing injuries before they occur. Preventive measures, through promoting positive health outcomes aligns very well with regenerative design and construction [5]. Regeneration in this context emphasizes the need to contribute positive outcomes. The bar that initially shifted from minimizing negative impacts to achieving net zero is now being raised to contributing to positive impacts. There is a growing body of researchers developing proactive solutions for injury prevention [6-8]. Their thinking is closely aligned with this the promotion of positive outcomes but there are some outstanding issues. A key challenge is developing a robust understanding of the underlying risk factors and the injury development process [9].

The slow progress in the development of more proactive injury strategies in construction can be largely attributed to this knowledge gap. The seriousness of this problem is exemplified in the prevalence of Musculoskeletal Disorders (MSD), which according to the National Institute for Occupational Safety and Health (NIOSH)’s definition is a “soft-tissue injuries caused by sudden or sustained exposure to repetitive motion, force, vibration, and awkward positions” that affect the muscles, nerves, tendons, joints and cartilage in the upper and lower limbs, neck and lower back. OSHA estimates that MSD accounts for nearly 33.33% of the total costs spent on worker’s compensation in the U.S. Employers spend as much as $20 million dollars annually on direct cost for MSD-related compensation. Between 2011 and 2014, the MSD-related injuries in construction increased by 14.6% [10]. The reported rate was more than double the average rate for all occupations. Rosenman et al. [11] point out that the problem could be worse given the fact that some work-related injuries go unreported.

Other challenges are related to the complexities surrounding the development of chronic disorders such as MSD. Understanding how such problems develop and evolve require a “multi-aspects assessment” of contributing factors [12]. Specific examples of MSDrelated contributing factors include prolonged force, repetitive motion, and overexertion [12,13]. These are often compounded by ergonomic factors such as vibration during working [14]. Managing these factors requires a robust understanding of ergonomics and drivers of behavior change. Clearly, the success of proactive safety management programs will be largely dependent on the availability of reliable data. Many of the safety programs rely on historical data was outlined in Finneran and Gibb [4] review of projects affiliated to CIB’s working commission on Safety and Healthy in Construction (W099). Although analysing the causation of accidents with historical data provides valuable information, real-time data is needed to promote injury prevention through an assessment of risk factors before problems develop into symptoms [8].

Lessons can be drawn from work in global health directed at advancing the understanding of how multiple factors interact with each other in an additive manner to trigger and compound a problem. Epidemiologists address the need for multi-aspects assessment through a “Web of Causation” approach [15]. Through system thinking and modelling methods, this approach provides a framework for an in-depth analysis of the underlying complexities [16]. The analysis of complex interaction among different variables cannot be done in an efficient and effective manner without robust tools, that can rapidly collect and synthesize vast volumes of data. These data-related needs are increasingly being met by using emerging Wearable Technologies (WT). The potential of WT is exemplified in posture and movement tracking applications for optimal performance in athletics [17] as well as healthcare [18]. The deployment of WT in injury prevention application has mostly been in a controlled physical environment that is different from the construction job site. In addition to the operations being executed outdoors, the specific location changes with each project [19]. The construction job site also relies on the input of temporary workers and a dynamic team [20].

This paper reports on preliminary findings from research directed at addressing these challenges through developing a construction industry specific framework for deploying WT. The authors propose an iterative, technology-push and market-pull approach collecting and synthesize real-time data, which can be used for proactive injury prevention. The main body of the paper outlines the pros and cons of existing sensor-based applications in closely related work. It also includes a critique of WT based on the experimental use of assessed two sets of sensor systems. The paper concludes with a description of future work in this research which will be directed at developing low-cost WT system. The initial prototype will target injury prevention for MSD.

Research Approach

The adopted methodology was based on a combination of a comprehensive literature review and experimental use of two lowcost sensor systems. The overarching objective here was assessing their effectiveness and efficiency in capturing and synthesizing data that can be used for MSD-related injury prevention. The identified sensor systems were assessed against the functional requirements for deployment and data collection on the construction site. Secondary data was obtained from repositories of cutting-edge gadgets such as the Wearable Technology platform [21]. The authors experimented with two low-cost sensors-Pocket Lab and LumoLift. The two authors were the subjects for the initial experiments. Pocket Lab is a combination sensor system, comprising accelerometers, gyroscopes, and thermometers. The focus here was using the gyroscope and accelerometer gyroscope and accelerometer to test the feasibility of using the Pocket Lab effectively to track posture. During the experiments, the Pocket Lab was attached to the centre of back. The subject repeatedly turned the upper body from left to right several times. They also bent the upper body as is shown in Figure 1. The gyroscope provides angle velocity while the accelerometer provides vertical acceleration. Pocket Lab comes with a smartphone app. This allowed the authors to visualize the captured data. The authors processed the data to derive the required posture related information. When the sensor system is placed vertical, the vertical acceleration is equivalent to gravitational acceleration (approximately 1g); when it is placed horizontally, the vertical acceleration is 0g. The turning angle between two continuing moments and bending angle in reference to vertical plane was calculated using Equation (1) and Equation (2).

figure 1:Measuring body movement with pocket lab.

For a specified time, T, AVi is angle velocity, VAi is vertical acceleration, and G is gravity.

A different set of tests was conducted using the Lumo Lift, which is a slouching prevention sensor system. It uses a wearable gadget and paired smartphone application. Each of the authors attached the gadget around the collarbone as shown in Figure 2. The gadget was left in place for two days.

figure 2:Test with lumolift.

Preliminary Findings

The prevalence of MSD in construction makes the sector an ideal testbed for the quantitative assessment and prevention of risk factors. Based on the analysis of causation factors, the authors established that the conventional and emerging tools for risk management are still not sufficiently developed. Conventional ergonomic assessment strategies include self-report, observation, and vision-based measurement in construction [22]. The development and progression of chronic problems such as MSD can be attributed to multiple contributing factors that interact with each other in an additive manner. These factors must, therefore, be characterized using a multi-aspect assessment approach. The underlying complexities can be mapped using the Web of Causation approach, which is a framework for capturing different causation factors in epidemiology. Clearly, managing risk factors through such an approach is a data-intensive undertaking.

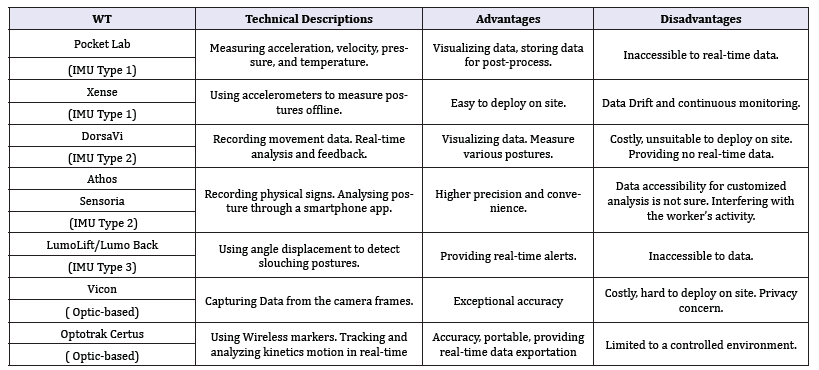

Emerging WT coupled with remote sensing application can be used as both data capture and processing tools. The systems with high potential for applicability in tracking posture and gait in construction can be broadly categorized into two groups - Inertia Measurement Units (IMU) and Optic-based sensors (Table 1). An IMU-based sensor typically contains gyroscopes and accelerometers, measures angular velocity and linear acceleration, reports a body’s specific, angular rate [23]. An Optic-based sensor converts light rays into electronic signals and measures posture changes via tracking the body attached markers’ movement [24]. Generally speaking there are 3 types of IMU-based sensor systems: Type 1. Exporting historical raw data stored in the sensor; Type 2. Turning raw data into physiological parameters (inaccessible raw data); Type 3. Analysing raw data to provide real-time feedback (inaccessible raw data).

Table 1:WTH reviews.

Significant progress has been made with respect to designing robust data capture and processing tools for managing the risk of chronic conditions such as MSD. This notwithstanding, there are still several outstanding challenges. One key barrier to the largescale deployment of WT in construction is their pricing. The WT with the highest potential for applicability in construction is also very expensive. The solution providers charge as much as $1,500 a person to track posture and gait for a fixed amount of time. Some providers retain control over the underlying algorithms and can charge as much as $10,000 to process captured data into actionable information. There are some additional size-related implementation barriers. The existing gadgets can create physical discomfort when worn and also interfere with the workers’ productivity [22,25]. In addition, the review of existing systems, which included conversations with business development representatives from two companies revealed that many of the existing WT solutions have been deployed as prototypes. Users usually do not have access to the collected data. This is because data collected through existing WT is analysed and interpreted by an application that is integrated or paired with the device as a closed system.

Some of these challenges were also observed during the experimental test. The data generated by the Pocket Lab cannot be used in its raw format. The authors had to interpolate it into variables that can be used to assess MSD-related risk factors. The data generated was also stored in the gadget before being exported. Although the LumoLift system monitors users’ postures in real-time, all the raw data and the underlying algorithm used to convert it into actionable information is hidden in a closed system. Warning vibration is triggered when a slouching posture is detected. The authors had concerns over its reliability because of the frequency of the vibrations. There was no way of verifying the accuracy of the system’s definition of a healthy posture because the underlying algorithm used to set off the trigger was not visible. There is also a potential user acceptance problem because of the frequency vibrations which over time can become a distraction to daily activities.

Conclusion and Further Work

This paper has described the opportunity to use preventative injury management to accelerate the progress towards the realization of zero injury and fatalities in construction. This need is greater in chronic diseases such as MSD, which when left unchecked result in health problems that escalate costs for employers. For example, in 2014, Workers’ compensation programs paid an estimated $62.3 billion in benefits across all sectors [26]. MSDrelated injuries in construction have been identified as one of the leading contributors to this problem. Because there are several complex contributing factors that result in the development of MSD, it will be difficult to characterize the underlying issues without a multi-factor assessment framework. The authors have presented the Web of Causation approach as a feasible solution to this need. There is also a need for robust data collection and processing tools. This paper has shown that significant progress has been made with respect to developing WT to address these needs.

The seriousness of MSD in construction has been driving the NIOSH’s consistent endeavours towards mitigating the MSD risks in construction. Exemplary efforts form NIOSH include

A. Developing both theoretical models and mobile application for calculating manual lifting risk index;

B. Proposing inexpensive simple tools or alternative practices for workers;

C. Large-scale surveillance of MSD risks using census data and survey, and

D. Facilitate transferring knowledge into MSD prevention practices. The proposed proactive prevention approach in this paper is aligned with the NIOSH’s on-going efforts.

Particularly, the miniature and wireless wearable IMU sensors can be a practical and affordable data sensing tool for construction workers. The collected motion data offer the chance for evidentbased quantitative MSD risk monitoring and assessment. Various human activity analysis can be conducted with the collected motion data, such as detecting MSD-related activities and inferring risk level. The risk monitoring result can also be used to trigger warning for real-time injury intervention. In summary, the proposed approach can be integrated into the current endeavours to facilitate quantitative MSD risk detection and assessment, and further propel the MSD intervention towards real-time level for workers in construction job site.

Despite the advantages from WT for collecting motion data, there are still outstanding challenges related to the use of existing solutions:

1) Pricing - many of the high potential systems are very expensive;

2) Working around the physical constraints of executing construction activities outdoors in a congested site;

3) The size of the gadget can create physical discomfort or interfere with the performance of work, and; 4) the high potential IMU-based sensor system does not provide access to actionable, real-time data.

These limitations will be addressed as part of the planned future work. The authors are working collaboratively with systems engineers to adapt and enhance two sensor systems. The first prototype will leverage on Mbient Lab, an IMU-based sensor unit. The second prototype will be based on the use of “tattoo sensors”, which are flexible, stretchable, and thin enough for direct attachment to the skin. The “tattoo sensors” have been previously used to measure motion change for flying drones in a lab-based setting [27-31]. Comparative studies will be conducted to assess the feasibility of deploying these sensors to address the data capture and processing requirements for preventing MSD-related injuries [32-35].

References

- Jaselskis EJ, Anderson SD, Russell JS (1996) Strategies for achieving excellence in construction safety performance. Journal of Construction Engineering and Management 122(1): 61-70.

- Sokas RK, Jorgensen E, Nickels L, Gao W, Gittleman JL (2009) An intervention effectiveness study of hazard awareness training in the construction building trades. Public Health Reports, pp. 161-168.

- Gillen M (2010) The NIOSH construction program: research to practice impact and developing a national construction agenda. Journal of Safety Research 41(3): 289-299.

- https://dspace.lboro.ac.uk/dspace-jspui/handle/2134/12523

- https://www.wbc16.com/media/cib-scpt-roadmapv3.pdf

- Carbonari A, Giretti A, Naticchia B (2011) A proactive system for real-time safety management in construction sites. Automation in Construction 20(6): 686-698.

- Zhang S, Teizer J, Lee J K, Eastman C M, Venugopal M (2013) Building information modelling (BIM) and safety: automatic safety checking of construction models and schedules. Automation in Construction 29: 83- 195.

- Hallowell MR, Hinze JW, Baud KC, Wehle A (2013) Proactive construction safety control: measuring monitoring and responding to safety leading indicators. Journal of Construction Engineering and Management 139(10): 04013010.

- Suraji A, Duff AR, Peckitt SJ (2001) Development of causal model of construction accident causation. Journal of Construction Engineering and Management 127(4): 337-344.

- https://www.bls.gov/home.htm

- Rosenman KD, Kalush A, Reilly MJ, Gardiner JC, Reeves M, et al. (2006) How much work-related injury and illness is missed by the current national surveillance system? J Occup Environ Med 48(4): 357-365.

- Rwamamara R, Lagerkvist O, Olofsson T, Johansson B, Kaminskas KA (2010) Prevention of work-related musculoskeletal injuries in construction industry. In proceedings of 10th international conference modern building materials structures and techniques, pp. 1292-1296.

- Alwasel A, Elrayes K, Abdel RE, Haas C (2013) A human body posture sensor for monitoring and diagnosing msd risk factors. In: 30th International Symposium on Automation and Robotics in Construction and Mining. Curran Associates Inc, Montreal, Canada, pp. 1322-1331.

- Kittusamy NK, Buchholz B (2004) Whole-body vibration and postural stress among operators of construction equipment: a literature review. J Safety Res 35(3): 255-261.

- Krieger N (1994) Epidemiology and the web of causation: has anyone seen the spider? Soc Sci Med 39(7): 887-903.

- Green LW (2006) Public health asks of systems science: to advance our evidence-based practice can you help us get more practice-based evidence? Am J Public Health 96(3): 406-409.

- Gruetzemacher R, Gupta A, Wilkerson GB (2016) Sports Injury Prevention Screen (SIPS): Design and Architecture of an Internet of Things (IoT) Based Analytics Health App. In: Interanion Conference on Informational Resources Management. Cape Town.

- Majumder AJA, Rahman F, Zerin I, Ebel W, Ahamed SI (2013) Prevention: Towards a novel real-time smartphone-based fall prevention system. In Proceedings of the 28th Annual ACM Symposium on Applied Computing: ACM, pp. 513-518.

- Dubois A, Gadde LE (2002) The construction industry as a loosely coupled system: implications for productivity and innovation. Construction Management & Economics 20(7): 621-631.

- Sydow J, Lindkvist L, DeFillippi R (2004) Project-based organizations embeddedness and repositories of knowledge: editorial. Organization Studies 25(9): 1475-1489.

- https://www.wearable-technologies.com/gadgets-of-themonth/? year=2016

- Wang D, Dai F, Ning X (2015) Risk assessment of work-related musculoskeletal disorders in construction: state-of-the-art review. Journal of Construction Engineering and Management 141(6): 04015008.

- https://www.cl.cam.ac.uk/techreports/UCAM-CL-TR-696.pdf

- Grattan KTV, Sun T (2000) Fibre optic sensor technology: an overview. Sensors and Actuators a: Physical 82(1): 40-61.

- Valero E, Sivanathan A, Bosché F, Abdel WM (2016) Musculoskeletal disorders in construction: a review and a novel system for activity tracking with body area network. Appl Ergon 54: 120-130.

- https://www.nasi.org/research/2016/workers-compensationbenefits- coverage-costs

- Jeong JW, Yeo WH, Akhtar A, Norton JJ, Kwack YJ, et al. (2013) Materials and optimized designs for human‐machine interfaces via epidermal electronics. Adv Mater 25(47): 6839-6846.

- Chen J, Ahn C, Han S (2014) Detecting the hazards of lifting and carrying in construction through a coupled 3d sensing and imus sensing system. Int Conf for Computing in Civil and Building Engineering, pp. 1110-1117.

- https://www.cpwr.com/publications/construction-chart-book

- https://www.bls.gov/data/#injuries

- Jebelli H, Ahn CR, Stentz TL (2014) The validation of gait-stability metrics to assess construction workers’ fall risk. In: International Conference on Computing in Civil and Building Engineering, pp. 997-1004.

- Park MW, Makhmalbaf A, Brilakis I (2011) Comparative study of vision tracking methods for tracking of construction site resources. Automation in Construction 20(7): 905-915.

- Saito H, Watanabe T, Arifin A (2009) Ankle and knee joint angle measurements during gait with wearable sensor system for rehabilitation. In World Congress on Medical Physics and Biomedical Engineering, pp. 506-509.

- Watanabe T, Saito H (2011) Tests of wireless wearable sensor system in joint angle measurement of lower limbs. Conf Proc IEEE Eng Med Biol Soc 2011: 5469-5472.

- Yang K, Aria S, Ahn CR, Stentz TL (2014) Automated detection of nearmiss fall incidents in iron workers using inertial measurement units. In Construction Research Congress, pp. 935-944.

© 2018 Esther Obonyo. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)