- Submissions

Full Text

Advancements in Civil Engineering & Technology

The Usage of a Locomotive Tractive Power in the Different Operating Modes and the Efficiency Control

Alexander Jr Zarifyan*

Rostov State Transport University, Russia

*Corresponding author: Alexander Jr Zarifyan, LLC „INTELPRO TMH” leading traction system engineer, Rostov State Transport University, Mashinostroiteley St., Novocherkassk, Russia

Submission: July 11, 2018;Published: August 24, 2018

ISSN 2639-0574Volume2 Issue1

Introduction

A significant share of energy consumed by rail systems is used to move the trains [1]. In our opinion, it is necessary to study carefully the efficiency of freight electric locomotives in different modes of operation.

Modern freight electric locomotives have a multi-engine electric traction drive (up to 16 traction motors) with tractive effort control system on each axle. Therefore, the approach of the Scalable Power Control Technology [2,3], which regulates the quantity of locomotive traction motors (TM) in traction mode, seems quite reasonable. In our case, if full locomotive tractive power is not needed within operation, the redundant motors must be automatically switched off [4,5]. But when additional tractive power is required, the locomotive must use sufficient number of motors.

The goal of this paper is to analyze the indicators of freight locomotive efficiency in different operational modes and searching for dependences of electric locomotive efficiency, also representation of the electric locomotive efficiency control system [6,7]. As a result, energy consumed by locomotives can be reduced.

The object of this abstract is the double-section 8-axle heavy freight electric locomotive 2ES5 «Scythian» [8] produced by CJSC «Trans-mash holding». The locomotive is powered by AC 25kV, 50Hz network. The nominal tractive power is 8800 kW. In each section, there are four independent power channels. Each channel contains main transformer winding, 4qs-rectifier, autonomous voltage inverter and traction motor. The energy efficiency of an electric locomotive is characterized by its coefficient of performance (COP, i.e. locomotive efficiency) and its capacity of utilization coefficient (CUC). It is necessary to distinguish between the locomotive’s COP in nominal power stationary mode (a precise value of this COP is listed in the technical documentation), and the operational COP. Locomotive’s operational efficiency depends on operational modes at different time allocations [9].

Methods

There are still significant opportunities to reduce the electrical energy consumption when the locomotive operates at incomplete load. As a matter of fact, the freight locomotives of JSC “Russian Railways” mainly work on “round-trip” lines. In forward direction, a locomotive drives a heavily loaded train weighing 6000 tons or more, and nearly all the power capacity is used. But in the reverse direction, the locomotive drives an empty train which weighs 3-4 times less, and the locomotive power is used only partially.

The heavy train experiences

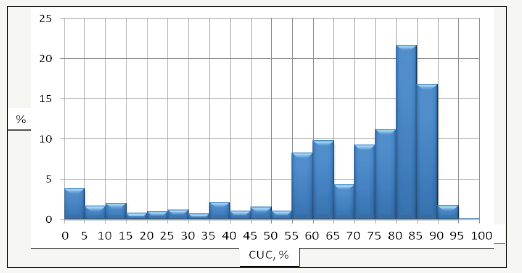

There was an experienced ride with 9090 t freight train in February 2018. The train went uphill on 9.1% slope. The ride of 21,7km distance continued for 43min. This test ride was successful, the wheels slip speed and traction motors temperature were normal. The CUC average value is 82.4%. The COP average value is 82%. The locomotive power is most fully used in acceleration modes and on the uphill with heavy train.

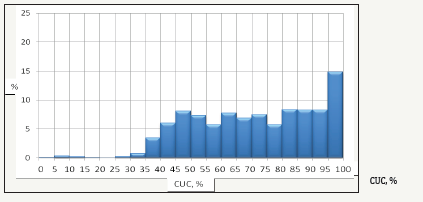

figure 1:9090 t train on uphill. Distribution of consumed energy (%) by the degree of power use

The regular experience

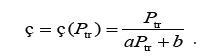

On the flat railway with empty train, locomotive tractive power is used in part. As an example, let consider the ride on flat railway. The train weighs 2192t. A 108km ride takes 142min. The average value of the locomotive efficiency on the flat way is 72%. The average value of the capacity of utilization coefficient is 10.4%. Let us compare bar charts for heavy uphill ride (Figure 1) and regular ride on flat railway (Figure 2). Efficiency COP and usage of locomotive power CUC is greatly less on a flat railway with a light train. After considering these examples, let’s try to find the way to increase efficiency in light operational modes.

Results

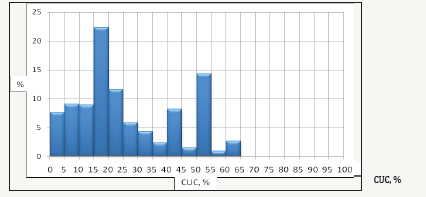

Because the locomotive 2ES5 has data recorder on board, a lot of experimental data was collected in different operational modes. Let’s show efficiency of an electric locomotive in traction mode, depending on tractive power on Figure 3 [5-7]. The analytical dependence of the electric locomotive efficiency on the tractive power was found by statistical processing (look at red line on Figure 3):

Coefficients a=1.055, b=564.3 with 0.95 confidence interval.

figure 2:2192 t train on flat way. Distribution of consumed energy (%) by the degree of power use

figure 3:Efficiency of an electric locomotive in traction mode.

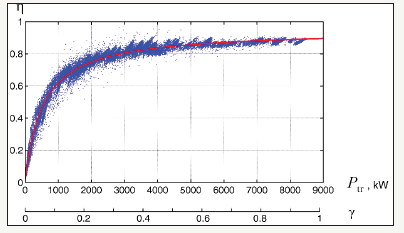

figure 4:Computer simulation (DAC) of 2192t train on flat way. Distribution of consumed energy (%) by the degree of power use

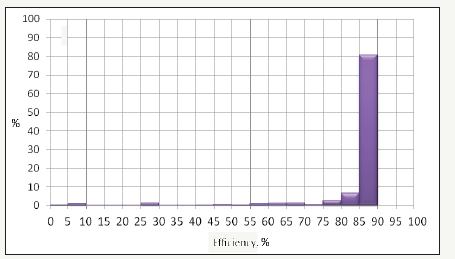

figure 5:Computer simulation (DAC) of 2192t train on flat way. The distribution of energy consumed by an electric locomotive (%), according to the efficiency of its transformation into useful work.

Results and dependencies allowed us to develop algorithm of increasing locomotive efficiency: Discrete-Adaptive Control system (DAC). This control system distributes tractive effort to optimum quantity of traction motors, and redundant motors are switched off [6,7]. Switched-on motors are using by almost full power, so and they have high efficiency. To determine the optimum quantity of motors in the traction mode, we choose capacity utilization coefficient as a criterion. The efficiency control system was checked by computer simulation on 108km flat way under the same conditions as real ride from above in this paper. Traction motors quantity regulator was added in detailed rolling stock computer model. Results are shown on Figure 4 (to compare with Figure 3) and Figure 5. In computer simulation of the DAC algorithm, with the same executed useful work, the energy consumption from the catenary decreased from 3017 to 2623kWh, or by 13%. An average locomotive efficiency reached 84%, compared to 72% efficiency in the sample ride. The distribution of energy consumed by an electric locomotive (%), according to the efficiency of its transformation into useful work.

Conclusion

a. Indicators of freight locomotive efficiency in different operational modes were analyzed.

b. Dependence of electric locomotive efficiency on the tractive power was found by statistical processing of experimental data.

A locomotive efficiency discrete-adaptive control system is represented. This control system increases the locomotive efficiency by distributing tractive effort to optimum quantity of traction motor.

References

- Brecher A, Sposato J, Kennedy B (2014) Best Practices and Strategies for Improving Rail Energy Efficiency: Technical reports. Office of Research and Development. Washington, USA.

- Bondi, André B (2000) Characteristics of scalability and their impact on performance. Proceedings of the 2nd International workshop on Software and performance,pp. 195-203.

- Ma K, Li X, Ming C, Wang X (2011) Scalable power control for manycore architectures running multi-threaded applications. ACM Sigarch Computer Architecture News 39: 449-460.

- Andryushchenko AA, Zarifyan AA, Kolpakhchyan PG (2015) Energy efficiency indicators of passenger electric locomotives with asynchronous traction drive feeding from DC contact network. Izvestiya PGUPS 2: 21-29.

- Andryushchenko AA, Zarifyan AA, Kolpakhchyan PG (2015) Increasing energy efficiency of electric passenger locomotives with asynchronous locomotive driving unit. Proceedings of Petersburg transport university 4: 5-14.

- Zarifyan AA (2016) Algorithm for increasing the energy efficiency of electric locomotives with asynchronous traction drive feeding from DC contact network. Vestnik RGUPS 1: 50–61.

- Andryushchenko AA, Zarifyan AA, Orlov Yu A, Soltus KP (2017) Method of locomotive energy efficiency control when working with partial load. Patent RU 2617857.

- https://www.alstom.com/products-services/product-catalogue/railsystems/ trains/products/prima-heavy-freight-locomotives

- Gapanovich VА, Avilov VD, Arjannikov BA (2012) Energy saving in railway transport. In: Gapanovich VA (Ed.), MISiS Publishing House, Moscow, p. 620.

© 2018 Alexander Jr Zarifyan. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)