- Submissions

Full Text

Advancements in Civil Engineering & Technology

Modernization Instruments for Technical Diagnostics Machines

Kirill Epifantsev*

Saint-Petersburg State University of Aerospace Instrumentation, Russia

*Corresponding author: Kirill Epifantsev, Saint-Petersburg State University of Aerospace Instrumentation, Russia

Submission: March 16, 2018; Published: April 03, 2018

ISSN 2639-0574Volume1 Issue1

Introduction

The development of non-destructive testing in Saint-Petersburg State University of aerospace instrumentation (SUAI) is reflected in the appearance of new terms that are used in practice, scientific papers and technical descriptions. Non-destructive control increasingly contacts with adjacent areas involved in assessing the actual technical condition of the facilities, determining the possibility of their further operation and the terms of safe operation (resource problem). In this paper, the methods of non-destructive testing of industrial objects, as well as various types of this method, such as magnetic, electric, which are used to create new laboratory work in the educational process.

Materials and Methods

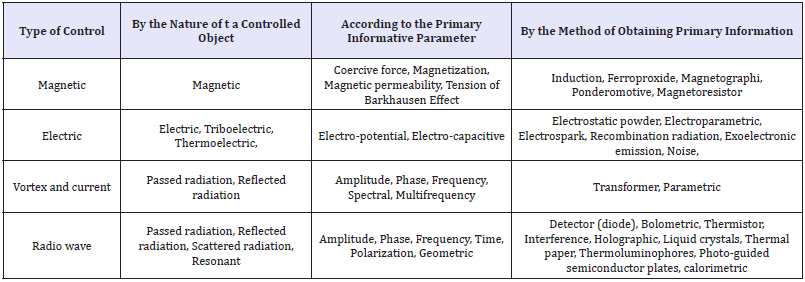

Table 1: Materials and Methods in SUAI.

The main methods of nondestructive testing are in Table 1

- magnetic - based on the analysis of the interaction of a magnetic field with a controlled object;

- electric - based on recording the parameters of the electric field interacting with the controlled object or arising in the controlled object as a result of external influence;

- eddy current - based on the analysis of the interaction of the electromagnetic field of an eddy current transducer with the electromagnetic field of eddy currents induced in a controlled object;

- radio wave - based on recording changes in the parameters of electromagnetic waves in the radio range interacting with a controlled object;

- Thermal - based on recording changes in thermal or temperature fields of controlled objects caused by defects [1-7].

Results

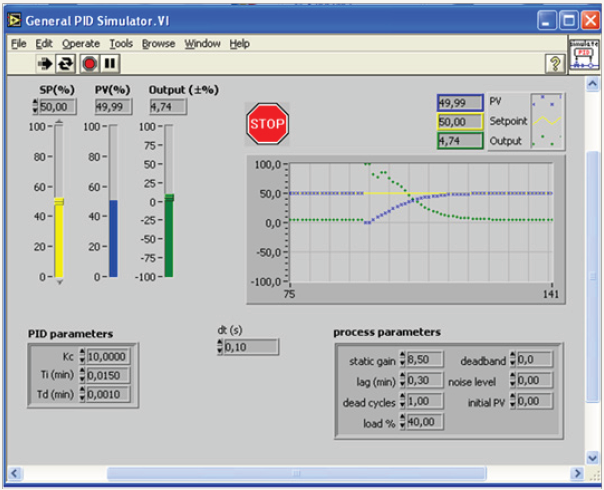

When studying these methods of monitoring to visualize the parameters of the installation, for students there were weighted similar stands in the National Instruments environment. This allows you to automate the research process and significantly save money for the research period Figure 1.

Figure 1: An example of a created measuring virtual instrument Non-destructive methods in Lab View.

Conclusion

The software allows simulating methods for diagnostics on the basis of application of virtual measuring instruments with minimal systematic error. This creates ideal conditions for the creation of new technologies in the field of innovation and the development of tools for express diagnostics of most technological processes.

Acknowledgement

The results of this work were marked on the Competition for the best scientific work about Earth (Tomsk Polytechnic University, 2012); Grant Competition of scientific works of graduate students (Government of St. Petersburg, 2012); Grant of the German Academic Exchange Service (DAAD 2012); The grant for young scientists (Government of St. Petersburg, 2017).

References

- (2018) Non-destructive testing.

- (2017) Methods of conducting non-destructive testing.

- GOST 18353-79 (1980) Non-destructive testing classification of species and methods. In exchange for GOST 18353-73, Moscow, Russia, p. 12.

- (2002) Manual the non-destructive testing system, Types methods and technology of nondestructive testing, Terms and Definitions.

- (2018) The main factors that determine the choice of the method of control.

- (2016) Vibro-acoustic control.

- (2017) Non-destructive methods of control.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.jpg)

.png)

.png)

.png)