- Submissions

Full Text

Research & Development in Material Science

Effect of Sintering Temperature and Two-Stage Alloying on the Microstructure and Hardness of Tungsten Heavy Alloys W-Ni-Co

Mohammad Reza Samadi1*, Mahdi Raoufi2, Majid Zarezade Mahrizi2 and Zeinab Malekshahi Beiranvand3

1Master graduated, Materials Science and Engineering Department, Faculty of Engineering, Arak University, Iran

2Assistant Professor, Materials Science and Engineering Department, Faculty of Engineering, Arak University, Iran

3PhD graduated, Materials science and engineering department, Faculty of engineering, Tarbiat Modares University, Iran

*Corresponding author: Mohammad Reza Samadi, Master graduated, Materials Science and Engineering Department, Faculty of Engineering, Arak University, Iran

Submission: January 03, 2022;Published: January 24, 2022

ISSN: 2576-8840 Volume 16 Issue 3

Abstract

The main problem in production of Tungsten Heavy Alloys (THA) is the high specific weight and melting point of the tungsten element. Nowadays, powder metallurgy plays a great role in production of these alloys. In this study, W-8Ni-2Co alloys was produced by powder metallurgy method at different condition and their microstructure and properties were investigated. For this purpose, one sample with the one-stage alloying condition was produced at 1450 ̊C sintering temperature and other samples having the same composition, were produced at 1350, 1400 and 1450 ˚C sintering temperatures in two-stage alloying condition. Scanning Electron Microscope (SEM) images showed that at two-stage alloying condition, the microstructure is more uniform and the W-W bonding reduces. In addition, it was shown that increasing the sintering temperature increases the diffusion of the bond phase (Nickel-Cobalt) and as a result, increases microstructure uniformity. The results of densitometry and micro hardness tests at the same chemical composition and sintering temperature showed that density and hardness of sample produced by two-stage alloying technique inceases16% and 31.6% respectively in comparison to the sample produced by one-stage alloying technique. Also, as the sintering temperature enhances the density and hardness increase from 15.4 to 16.832gr/cm3 and 525.2 to 541.4 Hv, respectively.

Keywords: Tungsten Heavy Alloys (THA); One stage and two-stage alloying; Sintering; Temperature; Microstructure; Hardness

Introduction

Tungsten is known as a high melting point (3422 ˚C) metal. It is one of the principal materials for high-temperature applications such as cathode ray tube, and nozzle of the rocket motor, due to its particular characteristics including, high-temperature strength, high creep resistance, high thermal conductivity, high electrical resistance, the lowest vapor pressure, and the lowest heat transfer coefficient [1]. Furthermore, tungsten is one the most suitable materials for protecting against α and γ rays due its high density i.e. 19.3gr/cm3. However, the production process of this metal is difficult even at temperatures higher than brittle-ductile transition ranges, due to its high melting point, hardness and brittleness [2]. THA is a two-phase composite, which is composed of spherical particles of tungsten distributed in a ductile and low-temperature matrix such as nickel, iron, copper and cobalt. The ductile matrix is very effective on improving the mechanical properties of Tungsten. However, production of tungsten and its alloying through conventional methods is difficult due to the very high specific weight and high melting point. One of the most useful methods for production of tungsten and its alloys is powder metallurgy technique which is very remarkable nowadays. The biggest challenge of powder metallurgy processes of heavy metals is complex and costly powder making [3]. THA has high mechanical and sound physical features due to the presence of the tungsten phase with BCC lattice in a matrix with FCC lattice. These include high density of 16.8- 18.5gr/cm3, high strength of 1000-17000MPa, high ductility of 10- 30%, young modulus around 270-340MPa, approperiate thermal conductivity, and corrosion resistance. Thus, THA has potential to use in different applications such as counterweight and radiation absorbers. In addition, it is widely used in bullets and space rockets due to its high diffusive dynamic energy [4,5].

Currently, the main method for THA production is liquid phase sintering. When the sintering temperature is higher than the melting point of nickel (1455 ˚C) and lower than the melting point of tungsten (3410 ˚C), nickel as liquid phase fills the cavities between tungsten particles due to capillary force [6]. Addition of Nickel and cobalt to tungsten enhances sintering process via enhancing the diameter of throat regions [7].

Chen et al. [8] examined the effect of two-stage alloying on the microstructure of W-7Ni-3Co alloy and showed that two-stage alloying method prevents the creation of intermetallic compounds, increases the microstructure homogeneity and uniformity, reduces the W-W bonding and therefore increases the mechanical properties. German et al. [9] Investigated the effect of temperature on the activated sintering of tungsten in the presence of different amounts of nickel and cobalt. They showed that increasing the temperature enhances the density of samples. So that, by increasing the temperature the rate of density increase is reducing. The progress of sintering procedure was also observed in samples containing nickel, at all temperatures and all concentrations. That means, for beginning the tungsten sintering, nickel has higher activator power than cobalt. Also, it was shown that the growth rate of densification in samples containing nickel was reduced due to the growth of tungsten grains and periodization of remained vacancies [9].

The effect of sintering temperature on microstructure and hardness of W-8Ni-2Co alloy had not been investigated by researchers till now. In this study, the influence of increasing the sintering temperature on the microstructure and properties of the alloy was studied after two-stage alloying at three temperatures of 1350, 1400 and 1450 ˚C. Also, to compare the effect of two-stage alloying and one-stage alloying technique on properties, a sample with the same chemical composition was produced via one-stage alloying technique and sintering temperature of 1450 ˚C.

Experimental Procedure

The characteristics of tungsten, nickel and cobalt powders for the alloying process are presented in Table 1. The alloying procedure was done using a planetary stainless steel ball mill. Initial alloying powders’ mixture having W-8Ni-2Co composition was produced in 30 and 70 grams’ weight via one-stage and twostage alloying conditions, respectively.

Table 1: Characteristics of the produced powders for alloying.

In order to observe the morphology of initial powders, SEM images of powders was prepared. Tungsten, nickel and cobalt powders were mechanically alloyed in a planetary ball mill for 24 hours, 360 rpm rate and balls to powder weight ratio of 1:5. This examines the effect of single-stage alloying on the microstructure, mechanical and physical properties of the produced alloy (sample A). At first, the sizes of balls were chosen differently to obtain higher efficiency.

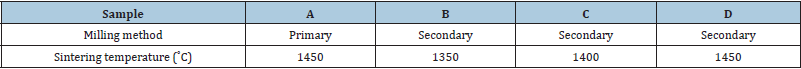

Two-stage alloying was performed for (B), (C) and (D) samples. The condition of alloying for these samples is shown in Table 2. In the first step, nickel and cobalt were alloyed together. Cobalt easily dissolves in nickel and creates a nickel-cobalt phase. In the second step, the created composition of the first step was alloyed with tungsten.

Table 2: Conditions of two-stage alloying.

Following the ejection of the powders from the milling box, alloying powders were compressed by a cold-pressing die applying 250MPa pressure. The mandrel having 10mm diameter and 8cm length was used. In order to perform the compressive operation on powders and improving their adhesion, a mixture of PVA binder and water were mixed in accordance with the following mechanism. Initially, 2wt% of PVA binder was added to 200mm distilled water. This compound was mixed on a magnetic stirrer-heater at 70 ˚C for 6 hours to get higher homogeneity and uniformity. Then, adequate time for final solution was given to reach the room temperature.

Compressed samples were inserted in a tube furnace for sintering. During the sintering of samples, a mixture of hydrogen argon gas having a 1:3 ratios was continuously blown. During the cooling of samples inside the furnace, 99.999 % pure argon gas was utilized. The properties of sintered specimens are observable in Table 3.

Table 3: Properties of specimens after sintering.

After sintering the samples, initial preparation was performed on the samples to examine microstructure and distribution of bond phase (nickel-cobalt) within the tungsten particles. The surface area of samples was coated with gold to increase the electrical conductivity and capturing proper micrographs. TESCAN-MIRA-III FE-SEM device was used to get micrographs and energy dispersive X-ray spectroscopy (EDS) analysis. The density of specimens was calculated by the Archimedes principle for bulk materials. After grinding and polishing the samples, the micro-hardness test was performed using a JENUS micro-hardness machine. 400gr loading for 20 seconds was applied for micro-hardness testing at room temperature and the average amount of 3 measurements were reported.

Results and Discussion

If tungsten, nickel and cobalt powder particles become alloyed simultaneously, the creation of an intermetallic compound in the alloy is possible. Thus, to prevent the creation of intermetallic compounds, nickel and cobalt were alloyed in the first step. Since nickel and cobalt do not make any intermetallic compound, cobalt easily dissolves in nickel and nickel-cobalt phase obtains. This mixture does not form an intermetallic compound with tungsten particles. So the resulted mixture is alloyed together with tungsten in the second step [8,10]. Finally, the created mixture is being sintered following the compression. Figure 1 shows the samples A, B, C, and D produced after sintering.

Figure 1: Illustration of samples A, B, C, and D after sintering.

Figure 2 depicts the result of the SEM images of initial powders. According to Figure 2, tungsten particles are almost spherical while, nickel particles have rectangle section and cobalt particles are quite worm shape.

Figure 2: SEM images of (A) tungsten, (B) nickel and (C) cobalt powders.

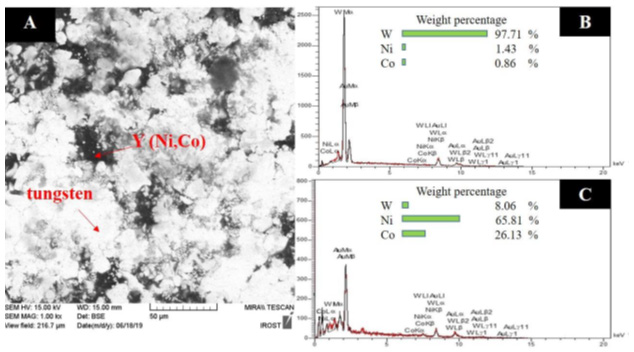

The deposition of nickel particles on the surface of powder particles in grain boundary areas creates nickel-rich areas as a solid solution phase. Tungsten atoms dissolve in this layer and reach to throat region due to the high diffusion rate and again dissolves in the throat region [11]. Figure 3 presents the SEM image and EDS analysis for sample A.

Figure 3: SEM image and EDS analysis for sample A. (A) SEM micrograph of the sample surface (B) EDS analysis for the white region (C) EDS analysis for the black region.

The SEM images of samples produced after sintering at various temperatures are displayed in Figure 4. According to Figure 4, the amount of uniformity increased after sintering. So that with increasing the sintering temperature, the black regions which are the bond phase of the nickel-cobalt system, have been welldistributed within the white regions of tungsten particles. This reduces the bonding of W-W particles as well, which are weak areas due to the brittleness and rapid crack growth [12]. In addition, with changing from one-stage alloying in sample (A) to two-stage alloying in samples (B), (C) and (D), the uniformity of the system can greatly increase, respectively. Because the bonding of W-W particles in the sample (A) is very strong and the bond phase in the microstructure has not been able to diffuse within the tungsten particles.

Figure 4: SEM micrographs of samples following the sintering. (A) sample A, (B) sample B, (C) sample C and (D) sample D.

It can be concluded that the effect of two-stage alloying on creating a uniform microstructure is much more compared to increasing the sintering temperature. Because amount of uniformity and distribution of bond phase increases with changing the alloying condition in samples (B) and (C) compared to sample (A), even in higher sintering temperatures. The greatest uniformity of bond phase distribution and accordingly, the weakest W-W bonding was observed in the microstructure of sample (D), produced with two-stage alloying and has the highest sintering temperature. The microstructure of W-8Ni-2Co alloy examined in present study and the microstructure of W-7Ni-3Co alloy examined in previous study [8] demonstrated the increased distribution of bond phase within the tungsten particles in two-stage alloying.

The results of energy dispersive X-ray spectroscopy (EDS) as shown in Figure 5 demonstrated the distribution of elements on the whole surface of samples have the same chemical composition of W-8Ni-2Co. In addition, the results showed that two-stage alloying and better distribution of bond phase (nickel-cobalt) cause increasing the presence of nickel and cobalt in the microstructure. Furthermore, increasing the sintering temperature enhances the diffusion of bond phase between tungsten particles which causes increasing the presence of nickel and cobalt in the microstructure.

Figure 5: Energy dispersive X-ray spectroscopy results for (A) sample A, (B) sample B, (C) sample C and (D) sample D.

The results of energy dispersive X-ray spectroscopy showed that the samples (B) and (C) have lower sintering temperatures, the quantity of nickel and cobalt in their microstructure is higher than the sample (A) due to the two-stage alloying conditions. That means the effect of two-stage alloying on the uniformity and distribution of the bond phase in the microstructure is more than the effect of increasing the sintering temperature.

The density of the samples was calculated from equation (1) where w is the real weight of the sample, w’ is the apparent weight of the sample, ρ’ is the density of utilized fluid, and ρ is the density of the sample. Equation (1):

The results of densitometry, observed in Table 4, shows an intense increase in the density values of two-stage alloyed samples due to the sound distribution of the bond phase between tungsten particles and filling the cavities and empty rooms. In addition, increasing the sintering temperature and as a result, increasing the diffusion of the bond phase and filling the cavities of the work piece enhances the density. As mentioned above, the amount of uniformity in the microstructure and distribution of the bond phase increases severely through two-stage alloying. Thus, the density of samples (B), (C) and (D) are much more than the sample (A).

Table 5 shows the result of surface micro-hardness testing. The average results of 3 measurements from different parts of the surface were reported.

Table 4: Result of densitometry test.

Table 5: Results of vickers micro-hardness testing.

According to the results, the hardness and uniformity of samples have direct relationship. In such a way that, increasing the uniformity and appropriate distribution of tungsten particles (which are the hard phase in the microstructure of heavy tungsten alloys) on the surface of samples increases hardness in the whole sample as well. According to Figure 6 for increasing the hardness of samples, the effect of two-stage alloying and performing uniformity and more distribution of the tungsten phase on the surface of samples is more than increasing the sintering temperature.

Figure 6: Comparing the effect of sintering temperature and alloying condition on the micro hardness of samples.

Comparing the micro-hardness values for samples with the same chemical composition and sintering temperature (1450 ˚C) but different alloying conditions, showed 32 % increasing in hardness of W-7Ni-3Co alloy and 31.6% increasing in hardness of W-8Ni-2Co alloy via two-stage alloying in these alloys [8]. Therefore, it was concluded that the effect of two-stage alloying in increasing the uniformity and appropriate tungsten phase distribution is almost the same for different compositions of heavy tungsten alloys. Also, it can be seen that increasing the nickel quantity (and thus improving sintering and reaching higher diffusion of bond phase between tungsten particles) in this research enhances the amount of hardness in W-8Ni-2Co alloy more than W-7Ni-3Co alloy. This increasing is 5.5% in one-stage alloying and 4.9% in two-stage alloying, respectively [8]. Increasing the microstructure uniformity of heavy tungsten alloys and suitable distribution of nickel-cobalt bond phase between tungsten particles improve the properties of the alloys. The result of this research showed that two-stage alloying condition and increasing the sintering temperature improve the uniformity of the system. Then improvement of system uniformity cause reduction of the W-W bonding which is brittle and reduces the mechanical properties of the samples. The density of samples increases due to the more uniform distribution of the bond phase in the microstructure that fills pores and closes cavities. Moreover, the hardness of samples increases via increasing the uniformity. And the proper distribution of tungsten particles in the microstructure as well, which are the hard phase of heavy tungsten alloys.

Conclusion

The key results of the preset study are as below: a) Two-stage alloying significantly increases the microstructure uniformity.

b) Increasing the sintering temperature from 1350 to 1450 ˚C increases the amount of bond phase (nickel-cobalt) diffusion in the microstructure. This increases the uniformity and proper distribution of the bond phase between tungsten particles.

c) Two-stage alloying enhances the density from 14.111 to 16.832gr/cm3 where chemical composition and sintering temperature are the same. Moreover, increasing the sintering temperature causes an enhancement of density from 15.4 to 16.832gr/cm3.

d) Applying two-stage alloying results in an addition of hardness of 370.5 to 541.4Hv. Also, increasing the sintering temperature causes hardness to increase from 525.2 to 541.4Hv.

e) The effect of two-stage alloying on increasing the microstructure uniformity and distribution of the bond phase is more than that for sintering temperature. Therefore, it can be concluded that two-stage alloying has a greater role in increasing the density and hardness of samples.

References

- Reiser J, Rieth M, Dafferner B, Hoffmann A (2012) Tungsten foil laminate for structural divertor applications-basics and outlook. Journal of Nuclear Materials 423(1-3): 1-8.

- Greger M, Čížek L, Widomská M (2004) Structure and mechanical properties of formed tungsten based materials. Journal of Materials Processing Technology 157: 683-687.

- Gong X, Fan JL, Ding F, Song M, Huang BY (2012) Effect of tungsten content on microstructure and quasi-static tensile fracture characteristics of rapidly hot-extruded W–Ni–Fe alloys. International Journal of Refractory Metals and Hard Materials 30(1): 71-77.

- Sunwoo A, Groves S, Goto D, Hopkins H (2006) Effect of matrix alloy and cold swaging on micro-tensile properties of tungsten heavy alloys. Materials Letters 60(3): 321-325.

- Srikanth V, Upadhyaya G (1984) Effect of tungsten particle size on sintered properties of heavy alloys. 39(1): 61-67.

- Wang GY, Gu SN, Yang S (2017) Microstructure and properties of tungsten heavy alloys fabricated by laser direct deposition. Materials Science and Technology 33(4): 415-420.

- Samsonov G, Yakovlev V(1969) Activation of the sintering of tungsten by the iron-group metals. 8(10): 804-808.

- Chen CL, Ma S (2018) Study on characteristics and sintering behavior of W-Ni-Co tungsten heavy alloy by a secondary ball milling method. Journal of Alloys and Compounds 731: 78-83.

- German R, Munir Z (1976) Enhanced low-temperature sintering of tungsten. Metallurgical Transactions A 7(12): 1873-1877.

- Bakar H, Handbook A (1992) Materials Park, Ohio, USA.

- Li C, German R (1983) The properties of tungsten processed by chemically activated sintering. Metallurgical Transactions A 14(10): 2031-2041.

- Wenqi G, Jinxu L, Cuicui L, Shukui L (2013) Asymmetry between compression and tensile properties of 80W-Cu Alloy. Rare Metal Materials and Engineering 42(11): 2289-2292.

© 2022 Mohammad Reza Samadi. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)