- Submissions

Full Text

Research & Development in Material Science

Improved Collectors for Flotation of Bastnaesite

Dylan Everly1, Corby Anderson1*, Vyacheslav Bryantsev2 and Santa Jansone-Popova2

Kroll Institute for Extractive Metallurgy, USA

Chemical Sciences Division, Oak Ridge National Laboratory, USA

*Corresponding author: Corby Anderson, Kroll Institute for Extractive Metallurgy, Colorado School of Mines, Golden, Colorado 80401, USA

Submission: April 01, 2018;Published: April 11, 2018

ISSN: 2576-8840

Volume5 Issue2

Introduction

Bastnaesite is an important mineral because of its abundance and rare earth content. Calcite and barite are the most common gangue minerals associated with bastnaesite. The importance of finding a suitable collector that can be selective against the gangue minerals without heated conditioning is critical to the advancement of the beneficiation of bastnaesite. This review will present some previous research that has been done on bastnaesite flotation and a comparison of new collectors used.

Background

Rare earth elements have been receiving a considerate amount of attention over the last few decades because of their increasing use and importance in today’s industry. Bastnaesite is a fluorocarbonate and is one of the most abundant minerals that contain rare earth elements. The major rare earth elements composing bastnaesite are cerium, lanthanum, and praseodymium, but this may differentiate between ore bodies. The major reserves of Bastnaesite are in China, United States, and Brazil [1]. Applications for the rare earth elements are: catalysts, glass coloring, phosphors, magnets, and polishing. Flotation is a preferred beneficiation technique for effective concentration of the Rare Earths [2-7].

Objectives

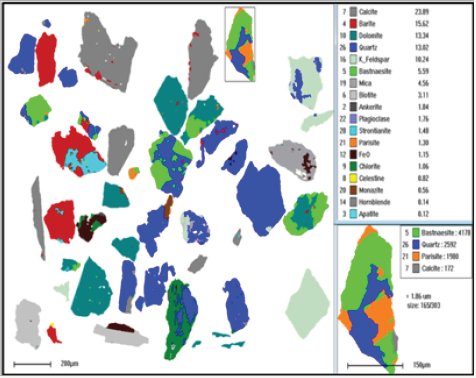

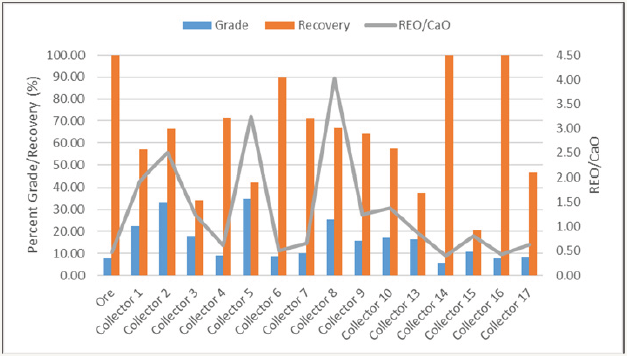

The first objective was to present a mineralogical analysis study of bastnaesite ore. This is shown in Figure 1. Next a literature study was performed and some reference is included. Finally, the goal of current work was to evaluate and optimize conditions for the top performing flotation collectors using micro flotation to achieve high selectivity for the beneficiation of bastnaesite and to improve recovery and economics of mining. These results are illustrated in Figure 2.

Figure 1: Automated mineralogical image of bastnaesite ore +100 mesh.

Figure 2: Micro flotation comparative testing of 17 novel collectors on bastnaesite ore.

Conclusion

A literature review was done on the beneficiation of bastnaesite along with detailed characterization of bastnaesite ore obtained from the Mountain Pass mine. Micro flotation studies were then performed, and candidate collectors were down selected from seventeen possible formulations based on the recovery and grade of desired and undesired minerals. The fundamental and further bench scale studies on the down selected collectors will be reported in subsequent publications.

Acknowledgement

This work was supported by the Critical Materials Institute, an Energy Innovation Hub funded by the U.S. Department of Energy, Office of Energy Efficiency and Renewable Energy, Advanced Materials Office.

References

- Gupta CK, Krishnamurthy (2005) Extractive metallurgy of rare earths. CRC Press, USA, pp. 1-484.

- Anderson CD (2015) Improved understanding of rare earth surface chemistry and its application to froth flotation. Doctoral Thesis, Colorado School of Mines, Golden, CO, USA, pp. 1-268.

- Anderson CD, Taylor P, Anderson CG (2017) Rare earth flotation fundamentals; a review. American Journal of Engineering Research 6(12): 155-166.

- Everly D (2017) Flotation of bastnaesite ore using novel collectors. MSc Thesis, Colorado School of Mines, Golden, CO, USA.

- Jordens AY, Cheng P, Waters KE (2013) A review of the beneficiation of rare earth element bearing minerals. Minerals Engineering 41: 97-114.

- Pradip (1981) The surface properties and flotation of rare-earth minerals. Doctoral Thesis, University of California, Berkeley, Berkeley, CA, USA.

- Pradip, Fuerstenau DW (2013) Design and development of novel flotation reagents for the beneficiation of mountain pass rare-earth ore. Minerals & Metallurgical Processing 30(1): 1-9.

© 2018 Corby Anderson. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)