- Submissions

Full Text

Approaches in Poultry, Dairy & Veterinary Sciences

Microbiological Quality Analysis of Raw and Pasteurized Milk Samples Collected from Addis Ababa and Its Surrounding in Ethiopia

Tamirat Tekilegiorgis1*

Department of Quality and Safety Assurance Directorate, Microbiology Laboratory Team, Leader, Ethiopian Meat and Dairy Industry Development Institute, Ethiopia

*Corresponding author: Tamirat Tekilegiorgis, Department of Quality and safety assurance Directorate, Microbiology Laboratory Team, Leader, Ethiopian Meat and Dairy Industry Development Institute, P.O.BOX 157 Bishoftu, Oromiya, Ethiopia

Submission: August 02, 2018; Published: August 17, 2018

ISSN: 2576-9162 Volume4 Issue5

Abstract

This study was conducted to evaluate microbiological quality of raw and pasteurized milk samples collected from different locations in Ethiopia in 2016/2017G.c. Two types of milk samples were collected from different part of Addis Ababa and its surrounding of selected sites. A total of 48 samples were analyzed including 28 raw milk samples from the local producers, collectors and dairy markets and 20 different brands of pasteurized treated milk samples collected from different processing industries and from super market. The samples were examined for determining the Total Bacterial Count (TBC) and Total Coli form Count (TCC). The results revealed that the raw and half of pasteurized milk samples were substandard in terms of TBC and TCC. No growth in terms of TBC and TCC in sample number Ra-12 and no growth at TCC in sample number Ra-3. The range of TBC and TCC in raw milk samples was 5*103 to 3.18*108cfu/ml and 1.81*102 to 3.08*106cfu/ml, respectively. The TBC and TCC range in pasteurized milk samples was from 4.4*101 to 4.43*105cfu/ml and 4.5*101 to 2.3*104cfu/ml, respectively. In some samples the result was much greater of the recommended level by the Ethiopian Standards Agency /ESA/. Exceptionally sample numbers Pa1-6 and Pa-20 of pasteurized milk samples had no growth at all both in terms of TBC and TCC sample number pa-8, 9, 14, and 15 have no growth in terms of TCC. Statistical analysis of data revealed that there is significant difference between results of different samples which implies the contamination of raw and pasteurized milk is above standards. The finding of the study is an indication about the initial bacterial load in raw milk samples as well as in the processed milk sample. So from the consumer point of view, it needs high attention from the regulatory body and other concerned institutions especially on pasteurized types of milk because it is considered to be safe for consumption without any further treatment within the mentioned expiry date. Depends on the result this substandard/lower quality milk leads to high public health hazards. Besides, different regulatory bodies may also realize the importance of frequently inspection of the market milks to ensure whether they meet the minimum standers for the society in terms of quality and safety.

keywords: Addis Ababa; Ethiopia; ESA (Ethiopian standard Agency); Microbiology; Milk; Pasteurized; Raw; TBC (Total bacterial count); TCC (Total coli form count)

Introduction

Raw milk is milk produced by the secretion of the mammary gland of farmed animals, which has not been heated to more than 40 oC or has not undergone any treatment with an equivalent effect [1]. Pasteurization is a heating process to prevent the spoilage of milk. Pasteurization has been used since the early 1900s (heating raw milk to 16 oF for 15 minutes) is expected to remove microorganisms from milk [2].

Milk is one of the most important food products with livestock origin which enjoys special significance in terms of its various nutritional properties such as protein, lactose, fat, minerals and vitamins and other various ingredients dispersed in water, it is considered as complete diet [3] but at the same time, it is highly vulnerable to bacterial contamination and hence is easily perishable [4,5]. Milk is estimated to be sterile in healthy udder cells and not to contain bacteria in the mammary gland at the site of its production, unless there is an intra-mammary infection and/or the animal has a systemic disease .However, as soon as milk is excreted it is immediately colonized by a complex microorganisms that naturally dwell in the teat skin and the epithelial lining of the teat canal.

According to the Ethiopian Standards Agency (ESA) (Ref No ES 3460: 2009), the bacteriological quality of whole/raw cow milk is set to be less than 200,000, 200,000-1,000,000, 1,000,000- 2,000,000 and above 2,000,000 coliform units(CFU)/ml for Very good, Good, Bad, and very bad, respectively. Similarly, the grades of milk quality according to the total number of coliform plate count/ml is set to be less than 1000, 1000-50,000, 50,000-500,000 and above 500,000cfu/ml for Very good, Good, Bad, and very bad, respectively. These standards are more or less similar to other international standards according to different literatures. Again, according to the Ethiopian Standards specification for pasteurized liquid milk, to mention only the bacteriological grades, set by the ESA, the total plate count should be less than 50,000 and between 50,000 and 100,000cfu/ml for very good and good quality standards, respectively. The ESA recommends that milk with a total plate count above 100,000 shall not be offered for sale. Again it is indicated that no fecal coliform and not more than 10cfu/ml of non fecal coliform should be present in pasteurized milk.

Health requirements for production animals and hygienic requirements on milk production holdings (e.g., premises and equipment, hygiene conditions during milking, milk collection and transport, staff hygiene) are also regulated, in order to guarantee all the needed standards of microbiological characteristics. As a consequence, only reaching the legal standard is not ideal to stay in global market of dairy products. The safety of dairy products with respect to food born disease is of great concern around the world. This is especially true in developing countries where production of milk and various milk products takes place under unsanitary conditions and poor production practices [6]. The consumption of raw milk and its derivatives is also common in Ethiopia [7], which is not safe from consumer health point of view as it may lead to the transmission of various diseases. On the other hand bacteria can cause spoilage of the milk and spoilage and poor yields of products [8].

Many studies have been done on its constituents and physicochemical characteristics. From other important measures of quality in food industries and between customers, are microbial content and hygiene condition of the pasteurized and raw milk which can affect on the quality of raw, pasteurized milk and consequent products of them. Nowadays to conserve the customers` health, measures other than protein and fat content such as specific gravity, acidity, coli form and E. coli count, Solid Not Fat and total bacterial count are being determined for milk.

Contaminations of raw milk within milking process are originated from production in substandard way the udder, the exterior of the udder and the milking equipment used, air, feed, soil, feces, grasses and adulteration [9,10]. Another key issue often associated with the quality of milk is the dealers equipment used for transportation and storage are the source for the formation of bacterial biofilms, which may lead to an increased opportunity for microbial contamination [9,11,12]. It is hypothesized that the various ways in feeding and housing strategies of cows may influence the microbial quality of milk [10]. The water used for rinsing milking machine and equipment may also be responsible for the presence of high load of micro-organisms including pathogens in raw milk [13]. The coli form count is related to the unsanitary milking process and dirty cow`s environment [14]; Further contaminations increase for some reasons including the cooling and storage temperature plus holding time [15]. Milk quality in Ethiopia is still assessed by physical and chemical tests (milk density and fat content). Despite importance of hygienic and microbiological criteria at the farm level, there is not such information in retail milk products in Ethiopia the bacterial count is a useful method to measure milk quality.

Milk is normally sold as fresh and pasteurized to consumers in Addis Ababa. Approximately raw milk yield is around 4.6billion liter/year (CSA 2018 GC). In Ethiopia most of the produced milk used for production of different type of milk and dairy products such as whole and skim milk, yoghurt, flavored yoghurt, ice cream, butter and cheese . The rest raw milk is sold directly to consumers, for house consumption and traditionally boiled, then it changed to butter, cheese to the market and whey for home use.

The preamble of pasteurized processed milk in Ethiopia is passed for 5 decades and proved to be very adaptive and wellliked among consumers. Recently microbiological status of various types of treated milk is gaining a matter of great interest (society compliant in media Addis Tv). Due to the treatment process, high microbial load in milk is unexpected in the pasteurized milk after the date of manufacture, the recommended date of consumption for the pasteurized milk is 7 days. But the poor initial milk quality, defective processing or problem in preservation at the consumer side may deteriorate milk quality before the original date of expiry. The Ethiopian standard Agency (ESA) has set various chemical and sanitary requirements for the pasteurized milk. In order to protect the public health, microbiological assessments have an important role to play in the dairy industry. This will also reduce economic losses by the early detection of insufficient processing, packaging or refrigeration. Therefore this study was initiated to calculate the raw as well as pasteurized milk quality with the following specific objectives.

Objective

A. To evaluate microbiological quality of both raw as well as pasteurized milk samples and to compare them with the national standard.

B. To identify the risk areas of contaminant in the milk value chain and suggest corrective action.

Material and Methods

Study area and sampling procedure

The study population in this research was raw and pasteurized milk in Addis Ababa and it’s surrounding. The altitude is approximately 2355masl. The mean/ average minimum temperature was 16 °C and the maximum 20 °C, respectively. In this cross sectional study sampling was done by selecting different farmers, milk collectors, collection centers, shops/ super markets, and milk processing industries with random sampling and the others from retails representing pasteurized milk to customers.

Working place and study period

All the laboratory tests of this work were carried out in the Department of milk and milk product Quality and safety assurance directorate, Dairy Microbiology Laboratory, At Ethiopian Meat and Dairy Industry Development Institute, Bishoftu, Ethiopia from 2016 to 2017.

Sample collection

In this study, raw milk samples were purchased from local dairy markets, collection centers and the processed milks were bought from different shops/super markets and dairy processors in and around Addis Ababa city. A total of 48 samples were studied 28 raw milk (designated as Ra-1 to Ra-28) of the remaining 20 pasteurized milk (designated as Pa-1 to Pa-20) that are different brands. All the samples were aseptically collected using sterile test tubes and also with their pouch’s on a sample collector ice box at 4 °C and were transported to the laboratory without delay.

Microbiological Analysis

Standard plate count

The microbial content of milk indicates the hygienic levels during milking that include cleanliness of the milking utensils, proper storage and transport as well as the wholesomeness of the udder of the individual cow [16]. Standard Plate Count (SPC) is one of the most commonly used microbial quality tests for milk and milk products.

The total bacterial and coli form count was made by adding 1ml of milk sample into sterile test tube having 9ml peptone water. After thoroughly mixing, the sample was serially diluted up to 1:10- 3 and 1:10-7 and duplicate samples (1ml) were pour plated using 15-20ml autoclaved Standard Plate Count Agar (SPCA) and Violate Bile Red Agar (VBRA) solution then mixed thoroughly. The plated sample was allowed to solidify and then incubated at 37 ºC for 48 and 24 hours to SPCA and VBRA, respectively. Colony counts were made using colony counter [17].

After counting and recording bacterial colonies in each peterdish, the number of bacteria in millimeter milk was calculated by the formula given by American Public Health Association (APHA) [18]

Where: N= number of colonies per milliliter of milk,

ΣC = sum of colonies on plates counted,

n1 = number of plates on lower dilution counted,

n2 = number of plates in next higher dilution counted and

d = dilution from which the first counts are obtained.

When computing TBC and TCC, only the first two significant digits were recorded and the bacterial count was reported as colony forming unit per milliliter of milk (CFU/ml).

Data management and analysis

Bacterial count was done before the analysis and SPSS version 23 software was used for the analysis after Microsoft excel spread sheet was employed for raw data entry. Then the result interpreted as log10 transformation of descriptive statics and directly as it is.

Results and Discussion

Total bacterial count (TBC)

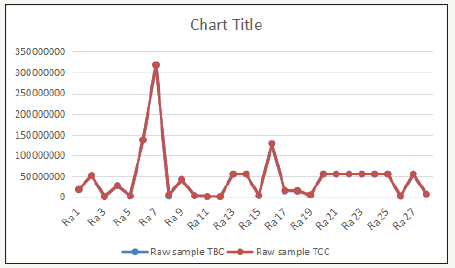

figure 1:Graphic representation of raw milk sample result.

Table 1:Result of raw milk sample.

Ra: Raw Milk Sample; TBC: Total Bacteria Count; TCC: Total Coliform Count

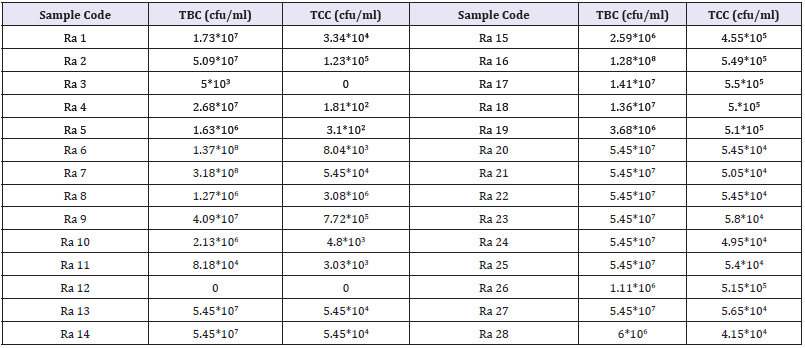

figure 2:Coli form bacterial growth in VBRA sample media

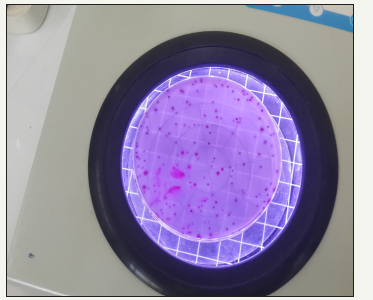

figure 3:Control media VBRA no growth

The total bacterial count is the number of bacteria in a sample that can grow and form countable colonies on Standard Plate Count Agar (SPCA) after being held at 37 °C for 48 hours. The results of bacterial distribution of the raw milk samples are presented in Table 1 and (Figure 1-3). The raw milk samples had high bacterial load which ranged from 5*103- 3.8*108cfu/ml (Mean 6.15log10 cfu/ ml). The most frequent cause of high bacterial load is normally as a result of poor cleaning of the milking system. Bacterial count may be high due to milking dirty udders, maintaining an unclean milking and housing environment and failing to rapidly cool milk to less than 40 °F [19]. The Mean TBC result of this study in raw milk was 6.15log10 cf/ml which is less than the study of [20] 7.58log cfu/ml in Bahir Dar Zuria and Mecha districts, Ethiopia; [21] 7.07log cfu/ ml in Debre Zeit town, Ethiopia, [22]. 7.07Log10 CFU/mlin DebreZeit town, Ethiopia. And the result by [23] who reported bacterial count from 7.36-7.88Log10 CFU/ml of raw cows’ milk in Borana, Ethiopia.

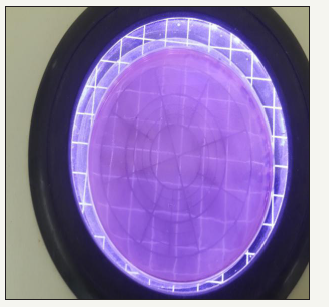

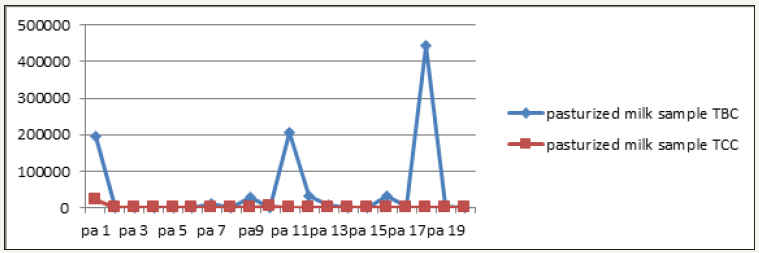

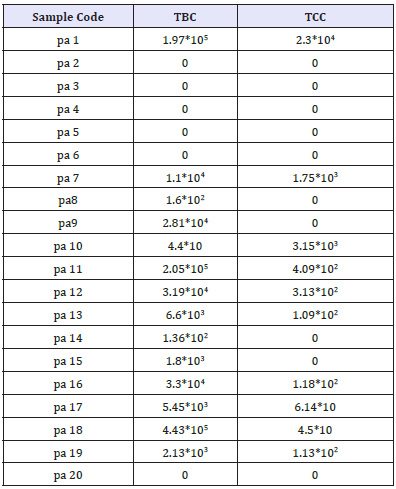

figure 4:Graphic representation of pasteurized milk samples.

Table 2:Result of pasteurized milk sample.

Pa: Pasturized Milk; TBC: Total Bacterial Count; TCC: Total Coli form Count

The TBC of the pasteurized milk samples in this study was ranged from 4.4*10 to 4.43*105cfu/ml (mean 2.42log10 cfu/ml) (Table 2) and (Figure 4), except sample number pa 11 and pa 18 the other milk samples are slightly lower than that recommended by ESA (not exceeding 50,000cfu/ml). This result was lower than [24] found the bacterial count in pasteurized milk samples were in between 7.5×107 to 1.24×108cfu/ml and The result of [25] who found 2.6*105 to 19*107cfu/ml. Interestingly, seven milk samples (pa1-6 and pa 20) showed no growth at all. As expected, TBC of each of the pasteurized milks in this study was not minimal or nil. This was an indication that there might be problem in pasteurization process.

Total coli form count

Average Coli Form Count (TCC) in the raw milks ranged from 1.81*102 to 3.08*106cfu/ml (Mean 3.59log10 cfu/ml) which was higher than that obtained by [26], who found TCC of < 1000cfu/ ml. However, when comparing this result with other countries the mean coliform counts 3.59log10 cf/ml of raw milk in this study is less than the reports of [27] from India (5.89log cfu/ml); [28] from Tanzania (5cfu/ml), and [29] from Kenya (4.67log cfu/ml) and [30] from Mali (6log cfu/ml).

The result of this study was much greater than study by [31] which founed 1.24log10 cfu/ml again it was greater than the study reported by [22] who reported a mean coliform count of 1.82Log10 CFU/ml raw milk sample in a study conducted in Debrezeit, Ethiopia. Reasons for higher coliforms counts in raw milk may be as a result of poor hygiene, contaminated water, unsanitary milking practices, and improperly washed and maintained equipment [32- 34].

The result of TCC in pasteurized milk in Table 2 and Figure 4 was ranges from 4.5*10 to 2.3*104cfu/ml this study was less than the study of [25] 1.2*105 to 6.9*104cfu/ml. The coli form bacteria are supposed to be absent in pasteurized milk as they can’t survive the pasteurization temperature. There are several reasons for the occurrence of bacterial contamination in the pasteurized milk samples such as defect in pasteurization machinery, to survive even after pasteurization, and contamination in the post-pasteurized process, contamination in packaging materials, defects in pipe lines, poor processing and handling conditions and/or maintenance of substandard hygienic practices by working personnel, milk quality, sanitation of process plant, [35] but TCC may still be detected in the pasteurized milk samples [33,34]. So the absence of bacteria in pasteurized milk revels the fact that the dairy company produced high quality of pasteurized milk. According to ESA not over 10cfu/ ml is acceptable for ‘Grade A’ pasteurized milk ES 3462:2009. These results of detecting the coli form bacteria test indicates that processed milk available in Ethiopia are of some are good quality and the greater are of very bad and will cause health risk to consumers so corrective action is necessary.

In Ethiopia milk is produced and marketed to consumer as raw and pasteurized or not subjected to quality standard. About 98% of the annual milk produced by subsistence farmers who live in rural areas where dairy products processing in the country is basically limited to smallholder level and hygienic qualities of products are generally poor [36]. Moreover, in the traditional practice the status of the cleanliness of the milkmen, the quality of water used for cleaning purposed not secured, the udder of the cow, the milking environment and the milking equipments could be the chief sources of the initial milk contamination [37].

The traditional milk equipment are reported to be often porous and therefore a reservoir for many organisms and difficult to clean [38]. All these reasons might increase the microbial load of milk produced in traditional practices of Ethiopia. Producers need to pay particular attention for the type as well as cleanliness of milk equipment. Milking equipment should be easy to clean. Aluminum and stainless steel equipment are mostly preferred [7].

Even if, it is not practical to produce milk that is always free of coliforms their presence in raw milk maybe tolerated. However, if present in large numbers, over 100 coliform organisms per milliliter of raw milk, it means that the milk was produced under improper procedures [39]. Hence their presence in large number in dairy products is an indication that the products are potentially hazardous to the consumers’ health [40].

Earlier research conducted in different part of the country revealed that the microbial counts of milk and milk products produced and marketed are generally much higher than the acceptable limits [41]. The higher number of cfu/ml implies that the sanitary conditions in which milk has been produced and handled are substandard subjecting the product to microbial contamination and multiplication. It is indicated that total bacterial count is a good indicator for monitoring the sanitary conditions practiced during production, collection, and handling of raw milk [42]. Hence training of milk handlers about hygiene can significantly reduce the bacterial load in milk. A good example for this could be reduced total bacterial count observed in milk sampled from farmers who received training on hygienic milk production and handling [43,44].

Conclusion

Milk and milk products play a crucial role in human nutrition both urban and pre-urban area of the country. However, evidences showed that the microbial properties milk and Ethiopian traditional fermented milk products made from different dairy producer were substandard in quality. This is due to absence of standard hygienic condition followed by producers during milk production. The hygienic conditions under smallholder conditions is limited to letting the calf to suckle for few minutes and/or washing the udder before milking. Moreover, unhygienic cleaning and handling of milk containers and inadequate dairy infrastructure coupled with limited knowledge of the hygienic production and handling of milk and milk products result in the contamination of the milk. Therefore, strict hygienic control measures along the food chain to improve the hygienic conditions of milk is necessary.

From this present study, it can be concluded that the microbiological quality of most of the raw milk samples and half of pasteurized milk collected from different areas of Addis Ababa and its surrounding were un satisfactory as indicated by their high bacterial loads and presence of coli-form bacteria which are public health concerns. After pasteurization treatment milk is expected to be safe but some of them were found to be un safe for the consumers. There is a need for improved communication to consumers on the hazards and control measures associated with consumption of raw drinking milk and improper pasteurized milk, Infants, children, pregnant women, old people and those with a weakened immune system have a higher risk of falling ill from drinking raw milk and such unsafe pasteurized milk or improper pasteurized milk.

There are standards for TBC and TCC internationally and nationally. The results clearly manifested that the milk hygienic quality is not satisfying for consumers because of milking methods, milk temperature, packaging, handling, cleaning, transportation, shops conditions (un proper refrigerators).

Recommendation

A. Only authorized producers registered for supplying raw milk through food graded materials and cold track transportation way are allowed to place raw milk to dairy processors.

B. Food graded materials have to be used to transport raw milk, the duration of transportation to consumption spots must be very short, raw milk is to be boiled before consumption and stored between 0 oC and 4 oC.

C. It is not allowed to stock any milk batch in the storage material for more than 24h, as certain pathogens are capable of multiplying at low temperatures and prolonged storage may boost their growth.

D. Any residual milk must be removed carefully and the machine must be cleaned prior to refilling. Internal and external cleaning procedures for milk container should be part of good hygienic practices (GHPs). The safety issue is that biofilms may survive the cleaning process. To that end, special cleaning treatments, e.g., pre-rinsing with water, circulation of sanitizing and/or alkali/acidic solutions and final cleaning with water are required.

E. The prompt application of a cooling treatment after milking and of cold temperatures for storage, which are a routine practice to control the microbiological quality and safety of raw milk, are thus not effective to have a fall-off in the growth rate of psychotropic bacteria early processing is necessary

F. Government role in the marketing system is a must thing to break the illegal trade system as well as to the promotion of the sector and the payment system has to be changed to quality based payment system

G. The food and medicine health administration control authority and other relevant stack holders must take more responsibility to control and reduce the risk of milk contamination as well as public health hazards in Addis Ababa and it’s surrounding without any excuses in this regard.

H. Specifically this listed sectors have a great role in the regulation, testing, supporting, taking action in the sector they have to play their Owen role in the development of the industries Ethiopian standard Agency (ESA), Ethiopian food, medicine and health administration control authority( FMHACA), Conformity Assessment (CA), Ethiopian public health institute (EPHI), Ethiopian consumer protection control authority (ECPA), Ministry of agriculture and livestock, Ministry of industry (MOI), Ethiopian meat and dairy industry development institute (EMDIDI).

I. Finally, consumers have to take some precautions because pasteurized and raw milk transportation from selling points to home, handling and storage practices can also be a critical point and potentially have an impact on the microbiological quality of drinking milk.

Acknowledgment

The author is grateful to the Ethiopian meat and dairy industrial development institute staffs especially for the department of milk quality and safety assurance directorate for their technical support in analyzing the sample and higher officials for availing facilities. In addition I would like to appreciate and give my gratitude to Dr. Tekeba Esheta and Mr. Kelifa Hussein for their valuable comment as well as W/ro Mekalia Bezabehe and W/ro Azeb Tessema for their help in laboratory testing and all participants.

References

- European Parliament and the Council of the European Union (2004) Regulation (EC) No 853/2004 of the European Parliament and of the Council of 29 April 2004 laying down specific hygiene rules for on the hygiene of foodstuffs. Official Journal of the European Union, pp. 1-151.

- Imele H, Kamage A, Mendi S (2002) Effect of pasteurization temperature on the total milk flora. Animal Health and Production in Africa 48(3): 177-181.

- Haug A, Hostmark AT, Harstad OM (2007) Bovine milk in human nutrition-A review. Lipids Health Dis 6: 25.

- Kim H, Hardy J, Novak G, Ramet JP, Weber F (1983) Off-tastes in raw and reconstituted milk. FAO Animal Production and Health Paper.

- OECD (2005) Dairy policy reform and trade liberalization. Organization for Economic Co-operation & Development Publishing, Paris, France.

- Mogessie A (1990) Microbiological quality of ayib, a traditional Ethiopian cottage cheese. Int J Food Microbiol 10(3-4): 263-268.

- Zelalem Y (2003) Sanitary conditions and microbial qualities of dairy products in urban and peri-urban dairy shed of the central Ethiopia. LAMBERT Academic publishing. p. 85

- Oliver SP, Jayarao BM, Almeida RA (2005) Foodborne pathogens in milk and the dairy farm environment: Food safety and public health implications. Foodborne Pathog Dis 2(2): 115-129.

- Latorre AA, Van Kessel JS, Karns JS, Zurakowski MJ, Pradhan AK, et al. (2010) Biofilm in milking equipment on a dairy farm as a potentialsource of bulk tank milk contamination with Listeria monocytogenes. J Dairy Sci 93(6): 2792-2802.

- Coorevits A, De Jonghe V, Vandroemme J, Reekmans R, Heyrman J, et al. (2008) Comparative analysis of the diversity of aerobic-spore-forming bacteria in raw milk from organic and conventional dairy farms. Syst Appl Microbiol 31(2): 126-140.

- Giacometti F, Serraino A, Finazzi G, Daminelli P, Losio MN, et al. (2012) Field handling conditions of raw milk sold in vending machines: Experimentalevaluation of the behaviour of Listeria monocytogenes, Escherichia coli O157:H7, Salmonella Typhimurium and Campylobacter jejuni. Ital J Anim Sci 11(1): e24.

- Marchand S, De Block J, De Jonghe V, Coorevits A, Heyndrickx M, et al. (2012) Biofilm formation in milk production and processing environments; influence on milk quality and safety. Compr Rev Food Sci Food Saf 11(2): 133-147.

- Bramley AJ, McKinnon CH (1990) The microbiology of raw milk. In: Robinson RK (Ed.), Dairy Microbiology: The Microbiology of Milk), Elsevier Science Publishers Ltd., London, pp: 163-208.

- Smiddy MA, Martin JE, Huppertz T, Kelly AL (2007) Microbial shelf-life of high-pressure-homogenised milk. International Dairy Journal 17(1): 29-32.

- Murphy SC, Boor KJ (2000) Troubleshooting sources and causes of high bacteria counts in raw milk. Dairy Food Environ Sanit 20(8): 606-611.

- Spreer E (1998) Milk and dairy product technology. Mixa, Marcel Dekker, INC., New York, USA, pp. 39-58.

- Marth EH (1978) Standard methods for the examinations of dairy products. American Public Health Association, Washington, DC, USA, p. 416.

- American Public Health Association (APHA) (1992) Standard method for the examination of dairy products, (16th edn), APHA, Washington, USA.

- Saxena M, Rai P (2013) Microbiological and chemical analysis of raw, pasteurized and UHT milk during preservation in India. Int J Chem Tech Res 5(6): 2804-2809.

- Asaminew T, Eyassu S (2010) Microbial quality of raw cow’s milk collected from farmers and dairy cooperatives in Bahir Dar Zuria and Mecha district, Ethiopia. Agriculture and Biology Journal of North America.

- Solomon M, Mulisa M, Yibeltal M, Desalegn G, Simenew K (2013) Bacteriological quality of bovine raw milk at selected dairy farms in DebreZeit town, Ethiopia. Compr. J Food Sci Technol Res 1(1): 1-8.

- Mosu S, Megersa M, Muhie Y, Gebremedin D, Keskes S (2013) Bacteriological quality of bovine raw milk at selected dairy farms in Debre Zeit town, Ethiopia. Comprehensive Journal of Food Sciences and Technology Research 1(1): 1-8.

- Worku T, Negera E, Nurfeta A, Welearegay H (2012) Microbiological quality and safety of raw milk collected from Borana pastoral community, Oromia Regional State. African J Food Sci Technol 3(9): 213-222.

- Hossain TJ, Alam K, Sikdar D (2010) Chemical and microbiological quality assessment of raw and processed liquid market milks of Bangladesh. Res J Dairy Sci 4(4): 28-34.

- Dealegn G (2015) Proceedings milk quality for consumers’ safety; Current status of raw and pasturized milk quality in the dairy industries in Ethiopia, Ethiopian meat and dairy industry developemnt institute (EMDIDI), Ethiopia.

- Saitanu IA, et al. (1996) Microbiological quality of raw cow milk. Thai J Vet Med 26(3): 193-214.

- Rai CK, Dwivedi HB (1990) Bacteriological quality of milk supplied in kanapur city by different sources. Indian Dairyman 42:520-523.

- Kurwijila RL, Hansen KK, Macha IE, Abdallah K, Kadigi HJ (1992) The bacteriological quality of milk from hand and machine milked dairy herds in Morogoro, Tanzania. Afr Livest Res 2: 59-67.

- Ombui JN, Arimi SM, Mcdermott JJ, Mbugua SK, GithuaAA, et al. (1995) Quality of raw milk collected and marketed by dairy cooperative societies in Kiambu District, Kenya. Bull Anim Health Prod Afr 43: 277-284.

- Bonfoh B, Wasem A, Traore AN, Fane A, Spillmann HC, et al. (2003) Microbiological quality of cows’ milk taken at different intervals from the udder to the selling point in Bamako (Mali). Food Control 14(7): 495- 500.

- Sisay M, Teka F, Ousman M (2015) Microbiological quality of raw cow’s milk from dairy farms in dire Dawa city, Eastern Ethiopia. World Journal of Dairy and Food Science 10(1): 9-14.

- Marjan S, Das KK, Munshi SK, Noor R (2014) Drug-resistant bacterial pathogens in milk and some milk products. Nutn Food Sci 44 (3): 241- 248.

- California Department of Food and Agriculture (2008) New Coliform standard for milk sold to consumers. California Department of Food and Agriculture, USA.

- Dey S, Karim MH (2013) Study on physicochemical and microbial quality of available raw, pasteurized and UHT milk during preservation. Int J Sci Invent Today 2(2): 150-157.

- Tekinsen KK, Elmali M, Ulukanli Z (2007) Microbiological quality of UHT milk consumed in Turkey. Internet J Food Safety 7: 45-48.

- Zelalem Y, Faye B (2006) Handling and microbial load of cow’s milk and irgo-fermented milk collected from different shops and producers in central highlands of Ethiopia. Ethiop J Anim Prod 6(2): 67-82.

- Haile W, Zelalem Y, Yosef TG (2012) Hygienic practices and microbiological quality of raw milk produced under Different farm size in Hawassa, Southern Ethiopia. Agricultural Research and Reviews 1(4): 132-142.

- O’Connor CB (1994) Rural Dairy Technology. International Livestock Research Institute (ILRI), training manual, Addis Ababa, Ethiopia, pp. 1-119.

- Walstra P, Wouters JM, Geurts TJ (2006) Dairy science and technology. (2nd edn), CRC Press Taylor & Francis Group, UK, p. 763.

- Godefay B, Molla B (2000) Bacteriological quality of raw milk from four dairy farms and milk collection center in and around Addis Ababa. Berl Munch Tierarztl Wochenschr 113(7-8): 276-278.

- Zelalem Y (2010) Microbial properties of Ethiopian marketed milk and milk products and associated critical points of contamination: an epidemiological perspective, East Africa Dairy Development (EADD) Program, Addis Ababa, Ethiopia.

- Fatine H, Abdelmoula E, Doha B, Hinde H, Abdelmajid S, et al. (2012) Bacterial Quality of Informally Marketed Raw Milk in Kenitra City, Morocco. Pakistan J Nutrition 11(8): 662-669.

- Nebiyu RG (2008) Traditional and improved milk and milk products handling practices and compositional and microbial quality of raw milk and buttermilk in Delebo water shade of Wolayita zone. MSc. Thesis, Hawassa University, Ethiopia.

- Sintayehu Y, Fekadu B, Azage T, Berhanu G (2008) Dairy production, processing and marketing systems of Shashemene- Dilla area, South Ethiopia. IPMS (Improving productivity and Market Success) of Ethiopian Farmers Project Working Paper 9. ILRI (International Livestock Research Institute), Nairobi, Kenya.

© 2018 Tamirat Tekilegiorgis. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)