- Submissions

Full Text

Research & Development in Material Science

Preparation and Relative Mechanical Strength of Erbium Monoselenide Films

Jabua Z*, Davitadze K and Minashvili T

Department of Engineering Physics, Georgian Technical University, Georgia

*Corresponding author:Jabua Z, Department of Engineering Physics, Georgian Technical University, Tbilisi, , Kostava-77, Georgia, Email:Z.jabua@hotmail.com

Submission: June 06, 2018;Published: August 20, 2018

ISSN: 2576-8840 Volume7 Issue5

Introduction

Compounds of rare-earth elements with elements of the sixth group of the chemical elements’ periodic table have an interesting electrophysical, optical and other properties [1,2], but their mechanical properties have not been studied. Recently, massive attention has been drawn to the mechanical properties of films since films with interesting electrical properties often exhibit low mechanical strength, which limits their practical application. The aim of the present work has been developing a technology for preparing thin ErSe crystal films on different substrates by vacuumthermal evaporation from two independent sources of erbium and selenium, and by the method of discrete vacuum-thermal evaporation, pre-synthesized ErSe compound and to study their relative mechanical strength using the full erasure method. ErSe films were deposited on a substrate rectangular parallelepiped glass-ceramic with dimensions of 8x15x1mm. Before the preparation of the films, the substrates were chemically cleaned in a mixture of nitric and hydrochloric acid and then washed with distilled water and heated in a vacuum at 650 K for 30 minutes. Experiments showed that films with good adhesion were formed on substrates treated in this way.

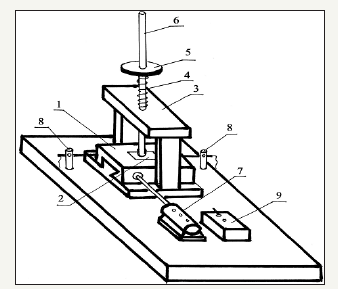

While the preparation of films by vacuum-thermal evaporation from two independent sources, the evaporation of Er and Se was carried out respectively at temperatures of 1250K and 645K, the distances from the evaporators to the substrates were 50mm and 35mm. The angle of slope between Er evaporator axes to the normal of the substrate surface was 250 of the Se evaporator - 400. The rate of deposition varied within ∼35-45Å /sec, the substrate temperature was the 650K. The thickness of the prepared films was 1.5-1.9μm. The source of Er was metal erbium, marked ErM- 1 in which the total content of Dy, Ho, Tm and Y was 0.1%, the source material also contained Fe 0.01%, Ca 0.01%, Cu 0.03%, Ta or Mo 0.02%. The source of Se was material high purity with Se content not less than 99.999 at%. According to X-Ray and electron diffraction studies the films have the structure of NaCl type with lattice constant a = 5.62 ± 0.05Å, which agrees well with the literature data for volumetric ErSe crystals a = 6.661Å [3]. ErSe films were also obtained by the method of discrete vacuum thermal evaporation of a pre-synthesized material. Temperature of the evaporator was 2700K, the substrate temperature - 570K. As well as in the first method a substrate was polycrystalline glass-ceramic. The deposition rate was ∼40-50Å/sec, the film thickness was 1.6- 2.0μm. Analysis of X-ray diffractograms and electron diffraction patterns showed that all films have the structure of NaCl with a lattice parameter a = 5.66 ± 0.05Å, which is close to date for films obtained by vacuum-thermal evaporation from two independent source components. In the presented work we investigated the relative mechanical strength of the prepared films by a complete attrition method. The essence of this method lies in the fact that the mechanical strength of the film and the degree of its adhesion to the substrate can be judged from the work that must be spent in order to completely erase the film from the surface of the substrate. The device for studying the relative mechanical strength of thin films by this method is shown in the Figure 1. It is similar to the one described in [4].

Figure 1:The scheme of installation for measurement the relative mechanical strength of films.

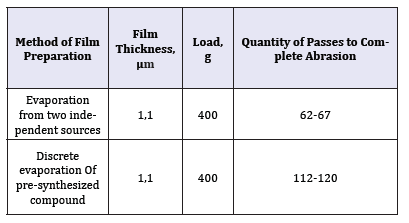

The test film (2) is attached to a massive plate (1). On the film, a rod (6) is supported from above, at the lower end where working material- a piece of suede is attached, which is covered with diamond paste. Load on the rod is carried out by different weights placed on the disk (5). The film moves forward and backward with a special mechanism (7,8) and counts the quantity of passes that are needed to completely erase the film. For the reliability of the result obtained, the investigations were carried out on films of the same thickness and under identical loads. The thickness of the all the studied films had the same thickness - 1.1μm, and the load was also the same and amounted to 400g. The data of the study of the relative mechanical strength of ErSe films prepared by a different technique on a glass-ceramic substrate are given on Table 1. As seen from the Table 1, relative mechanical strength of the films prepared by the discrete vacuum-thermal evaporation of the pre-synthesized material is almost 35% greater than the mechanical strength of the films prepared by vacuum-thermal evaporation from two independent sources.

Table 1:Relative mechanical strength of ErSe films prepared by different techniques on a glass-ceramic substrate.

Such a difference can be caused by the fact that, the crystal lattice of films prepared by discrete evaporation is more perfect than the structure of films prepared by evaporation from two independent sources. The results obtained are in good agreement with the data of [5].

Conclusion

For the first time was developed the technology of preparation of thin crystal films ErSe by method of vacuum-thermal evaporation from two independent sources of components and pre-synthesized ErSe volume material. The relative mechanical strength of the prepared films is studied by method of the complete attrition. It is shown that the relative mechanical strength of films depends on the method of preparation. Films prepared with method of discrete evaporation have considerably (30-35%) high mechanical strength, than films prepared with evaporation from two independent sources. It is possible, that it is connected to the fact that the crystalline structure of the films prepared with discrete evaporation is more perfect.

References

- Gasgnier M (1989) Rare earth compounds (oxides, sulfides, silicides, boron) as thin films and crystals. Phys Status Solidi A 114(11): 11-71.

- Verna AS (2009) Electronic and optical properties of rare earth chalcogenids and pnictides. African physical review 3: 11-29.

- Iarembash EI, Eliseev AA (1975) Chalcogenides of rare eart elements. Moscow, Russia.

- Sinelnikov KD, Shkliarevski NN (1950) Dependence of mechanical strength of aluminum coverings on glass substrate temperature. Works of physical office of physical and mathematical faculty of the Kharkiv State University of AM Gorky, Russia 950(2): 9-15.

- Jabua Z, Kupreishvili I, Gigineisvili A, Iluridze G, Minashvili T (2012) The international science conference dedicated to the 90th anniversary of Georgian Technical University. Transactions basic paradigms in science and technology development for the 21st century. The relactive mechanical strength of Prazeodium Diantimonide thim films. Tbilisi, Georgia, pp. 326-330.

© 2018 Jabua Z. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)