- Submissions

Full Text

Aspects in Mining & Mineral Science

Constructive Parameters of Open Pit Drmno Final Mine Slope in The Function of Diaphragm Wall Construction

Branko Petrović1* and Tomislav Šubaranović2

1 Electric Power Industry of Serbia, Serbia

2 Faculty of Mining and Geology, University of Belgrade, Serbia

*Corresponding author: Branko Petrović, Electric Power Industry of Serbia, Branch MB Kolubara, Lazarevac, Serbia

Submission: June 12, 2018;Published: August 31, 2018

ISSN 2578-0255Volume2 Issue2

Abstract

Drmno open pit exist in complex hydro-geological conditions and efficiency of exploitation significantly depend of god work of dewatering system. Dewatering system include future diaphragm wall on east and north mine boundaries. Constructive parameters of partial and general pit slope must provide not only maximal utilization of coal reserves but enough safety and stability of diaphragm wall. This paper present procedure of determination of general pit slope parameters in diaphragm wall zone.

Keywords: Slope stability; Open pit; Waterproof screen

Introduction

Drmno deposit is located in the eastern part of Kostolac coal basin, i.e. east of Mlava River. It comprises area of about 50km2. Eastern and southern boundaries of deposit are established by nature, meaning predisposed by geological conditions (outcropping and erosion). Northern boundary is represented by Danube River, although coal seam continually spreads under Danube and makes transition into Kovin deposit. North eastern boundary toward Danube and Kličevac village is established on the basis of insufficient number of explorations works. Western boundary is artificial and equivalent with eastern boundary of nearby Ćirikovac deposit (exploitation field).

The first exploratory boreholes in Kostolac basin were carried out in the eighties of 19th century, aiming to find the upper surface of the coal layer. Geologic explorations were performed in Drmno deposit area with shorter or longer breaks since 1944 up till today in several phases: 1950-1958, 1959-1969, 1975-1983, 1986-1989, 1990-2003, and since 2006 till today. Most exploration works were performed in the period till 1983 because of opening and working of Drmno open pit, which supplies steam power plant Kostolac B.

Based on data obtained by geologic and geophysical exploration works, and deep oil drillings, it has been found that Paleozoic crystalline schists and Tertiary and Quaternary sedimentary rocks make up Kostolac coal bearing area, and Drmno deposit as its part. Coal from Kostolac basin is mainly burned in thermopower plants and a smaller part is used for public consumptions. For continual operation of all four blocks in thermopower plants Kostolac with total power of about 1000 MW, including production of about 500.000 t of raw coal for public consumption, open pit mines would need to excavate and deliver in total 9*106 t of coal per year. After revitalization of blocks of thermopower plant Kostolac A and setting up blocks of thermopower plant Kostolac B in fully operational readiness, Kostolac’s thermo complex in next period should to be one of the most reliable electro power supplier in EPS [1-4].

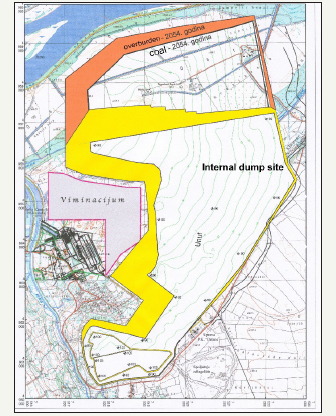

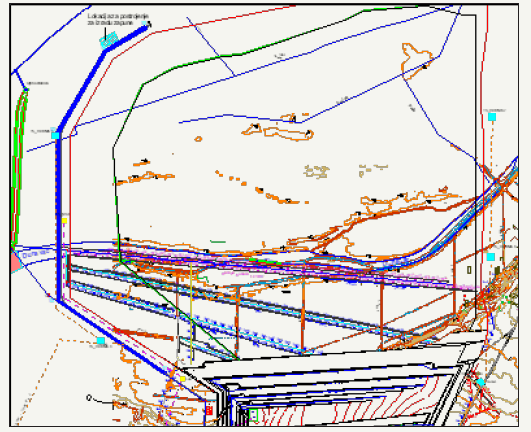

Blocks on location of thermopower plant Kostolac B are the newest ones in EPS system and its operation is planed up to 2020, when revitalization is planned, and then continuing of exploitation up to 2040. Currently thermopower plant Kostolac B, with total power of 697 MW (2*348,5 MW) supplied with coal from open pit mine Drmno which is designed for annual capacity of 9 million tons of coal. The overlying or underlying sediment and rocks of coal seams in basin contain water bearing strata (aquifer). Open pit mine development in such situation requires dewatering and depressurization of the aquifers through continuously pumping out of water to keep the mine pit dry and maintain safe working conditions. This potentially lowers the water table within and outside the mining area and makes water inaccessible for many operational shallow and/or deep tube-wells within the influence area, mostly used for irrigation and domestic purposes. Therefore, efficient water management is a critical issue for the successful operation of an open pit mine as well as to maintain the existing water supply system to the environment and community. In that case, like optimum solution for open pit water protection system include waterproof screen on the west and north-west side of mine (Figure 1 & 2).

figure 1:Final contour of open pit Drmno in the end of exploitation.

figure 2:Line of waterproof screen.

Slope stability in water prof screen zone

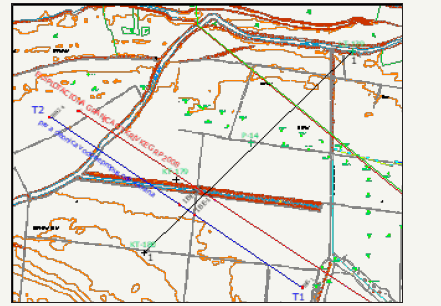

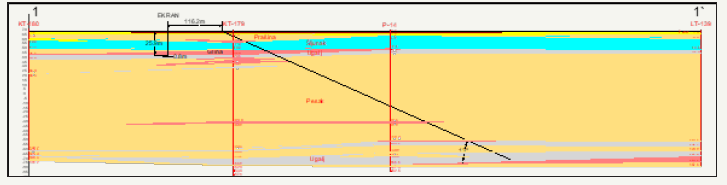

Influence of open pit slope on waterproof screen stability are investigate using results of new geotechnical and geomechanical investigation and using appropriate software for different conditions of pore-water preasure. Calculations of factor of safety are made on one characteristic section which is present on Figure 3 & 4.

figure 3:Location of first part of waterproof screen and section line 1-1`.

figure 4:Section 1-1` (L:H=0.5:1).

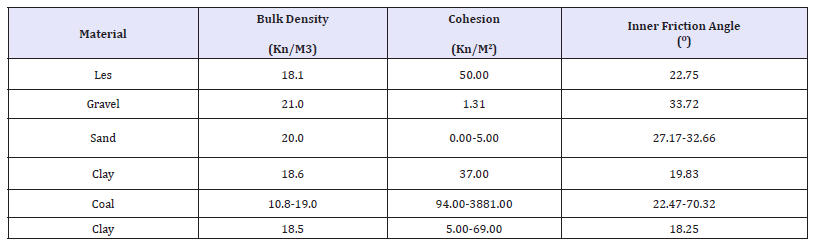

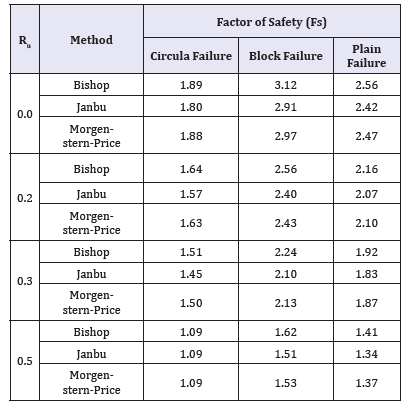

Using software uses limit equilibrium theory to compute the factor of safety of earth and rock slopes using a variety of methods to calculate the factor of safety. It has the ability to model heterogeneous soil types, complex stratigraphic and slip surface geometry, and variable pore-water pressure conditions using a large selection of soil models. Analyses can be performed using deterministic or probabilistic input parameters. In addition, stresses computed using finite element stress analysis may be used in the limit equilibrium computations for the most complete slope stability analysis available. Relevant geomechanically paremeters, for slope stability calculation are shown in (Table 1 & 2) (Figure 5-7).

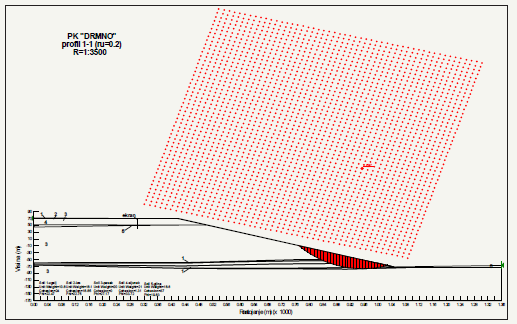

figure 5:Section 1-1`- critical circular failure with pore-water pressure ru=0.2 (Fs=1.63).

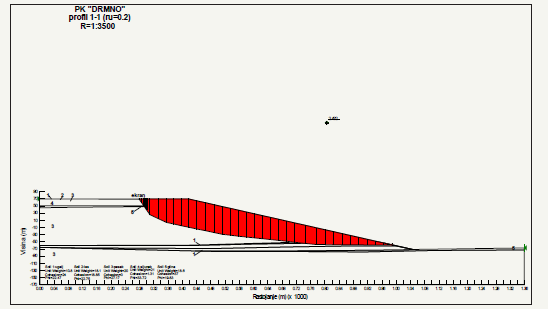

figure 6:Section 1-1`- critical block failure with pore-water pressure ru=0.2 (Fs=2.43).

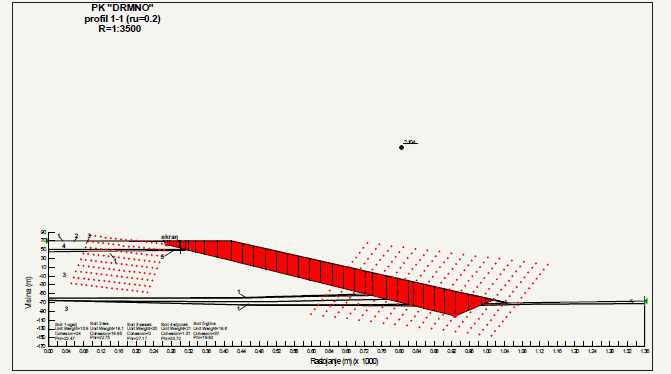

figure 7:Section 1-1`- critical plain failure with pore-water pressure ru=0.2 (Fs=2.10).

Table 1:

Table 2:

Conclusion

These work present results of calculation of safety factor of open pit final slope in zone of waterproof screen. Results of calculation clearly show interactive relationship between these two objects (open pit and waterproof screen) and it is necessary to manage mining works in this zone to function and stability waterproof screen would not be violated in the exploitation time.

References

- (2014) Technical mining project for open pit mine Drmno for a capacity of 9*106 tons of coal per year -Book No. 1 - Technical project exploitation, transport and disposal of overburden in open pit mine Drmno, University of Belgrade, Faculty of Mining and Geology, Belgrade, Serbia.

- (2014) Technical mining project for open pit mine Drmno for a capacity of 9*106 tons of coal per year -Book No. 2 - Technical project of exploitation and transportation of coal, University of Belgrade, Faculty of Mining and Geology Belgrade, Serbia.

- (2014) Technical mining project for open pit mine Drmno for a capacity of 9*106 tons of coal per year -Book No. 3 - Technical project digs protection of water, University of Belgrade, Faculty of Mining and Geology, Belgrade, Serbia.

- (2015) Simplified mining project on the rehabilitation drainage open pit coal Drmno, University of Belgrade, Faculty of Miningand Geology, Belgrade, Serbia.

© 2018 Branko Petrović. This is an open access article distributed under the terms of the Creative Commons Attribution License , which permits unrestricted use, distribution, and build upon your work non-commercially.

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

a Creative Commons Attribution 4.0 International License. Based on a work at www.crimsonpublishers.com.

Best viewed in

.jpg)

Editorial Board Registrations

Editorial Board Registrations Submit your Article

Submit your Article Refer a Friend

Refer a Friend Advertise With Us

Advertise With Us

.jpg)

.jpg)

.bmp)

.jpg)

.png)

.jpg)

.png)

.png)

.png)